Construction method for one-time turning of large-span T-shaped single pier

A construction method and swivel technology, applied in the field of swivel construction of T-structure bridges, can solve the problems of not being able to be in place at one time, unable to work at high altitudes, and slow construction progress, and achieve the effect of ensuring construction quality, reducing construction procedures, and improving construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

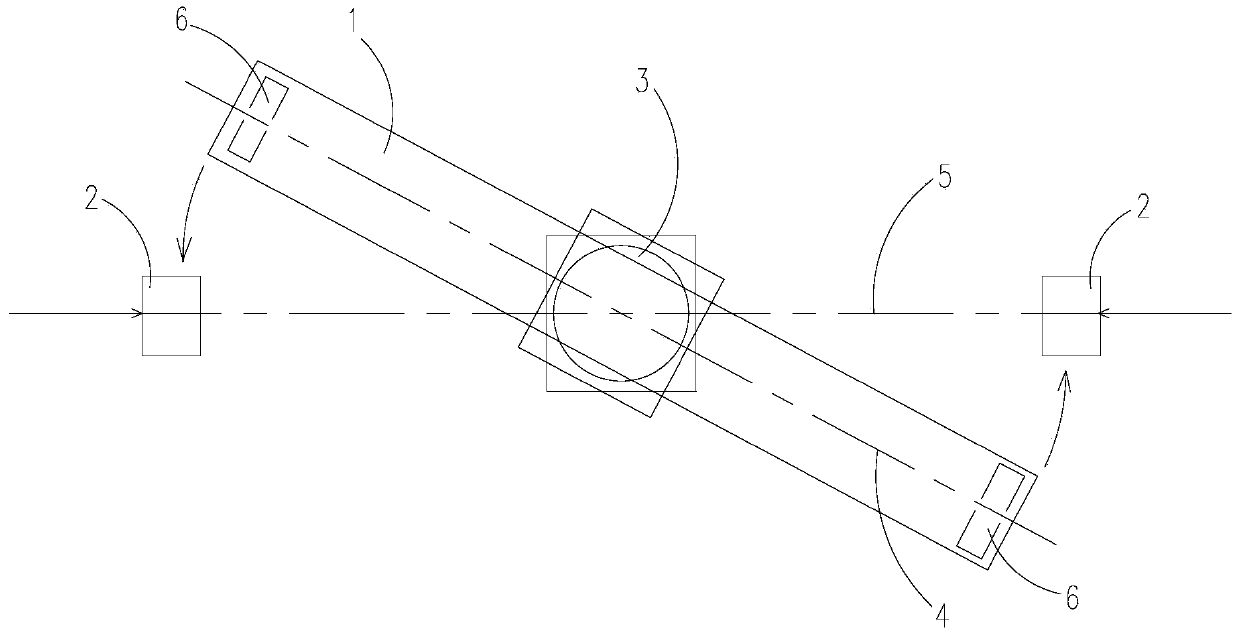

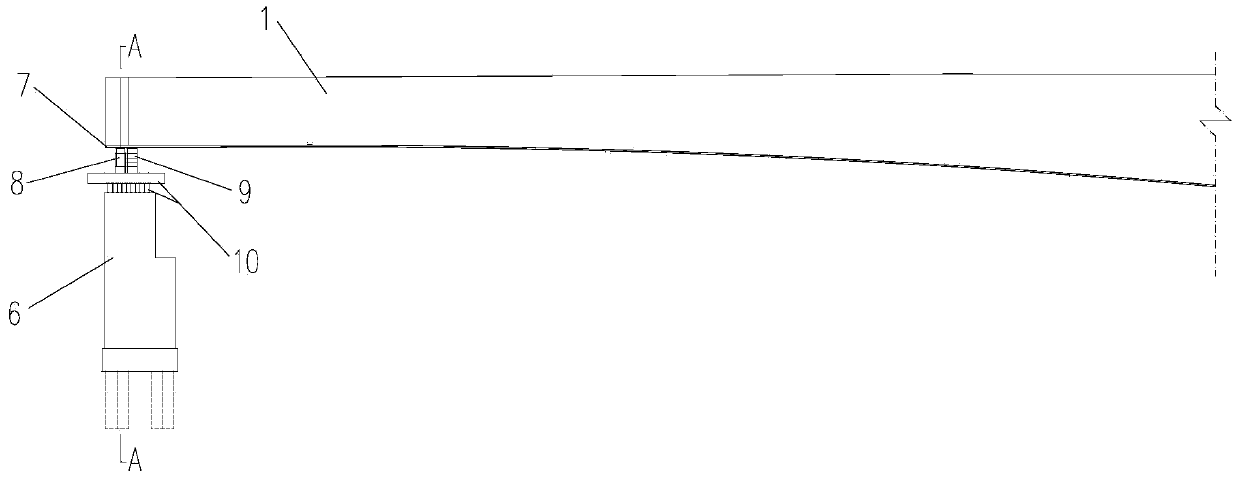

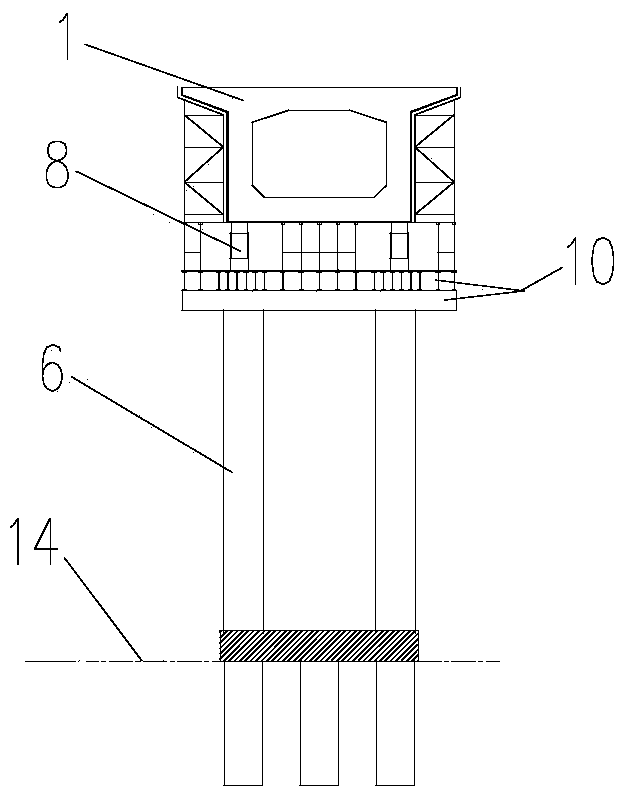

[0026] Such as figure 1 As shown, the construction method of one-time rotation of a large-span T-structure single pier is to carry out the construction and pouring of the swivel cap on the side that needs to cross the line obstacle or special section, install the swivel spherical joint 3 on the swivel cap, and then The beam sections are cast in-situ in large sections, and the beam sections are connected through wet joint construction to form a T-structure main beam 1 with a complete cantilever length. Temporary piers 6 are used to support both ends of the T-structure main beam 1 to prevent downward deflection. The control of the swivel traction system by the girder and synchronous control system realizes the balanced swivel of the main girder 1 of the T structure, and finally installs the support, pours the supporting pad stone 13, and completes the construction of the whole bridge. pass figure 1 The centerline 4 of the beam section before the rotation, the centerline 5 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com