Replaceable steel coupling beam and double-steel-plate high-strength concrete combined coupled shear wall

A high-strength concrete and shear wall technology, applied in the direction of walls, joists, girders, etc., can solve the problems of shear failure, large plastic deformation, and difficult replacement, and achieve the ability to improve the rapid recovery of functions, improve ductility, and improve brittle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

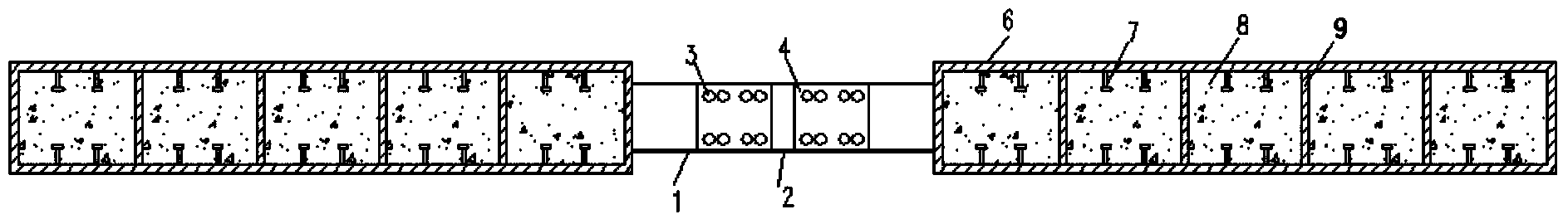

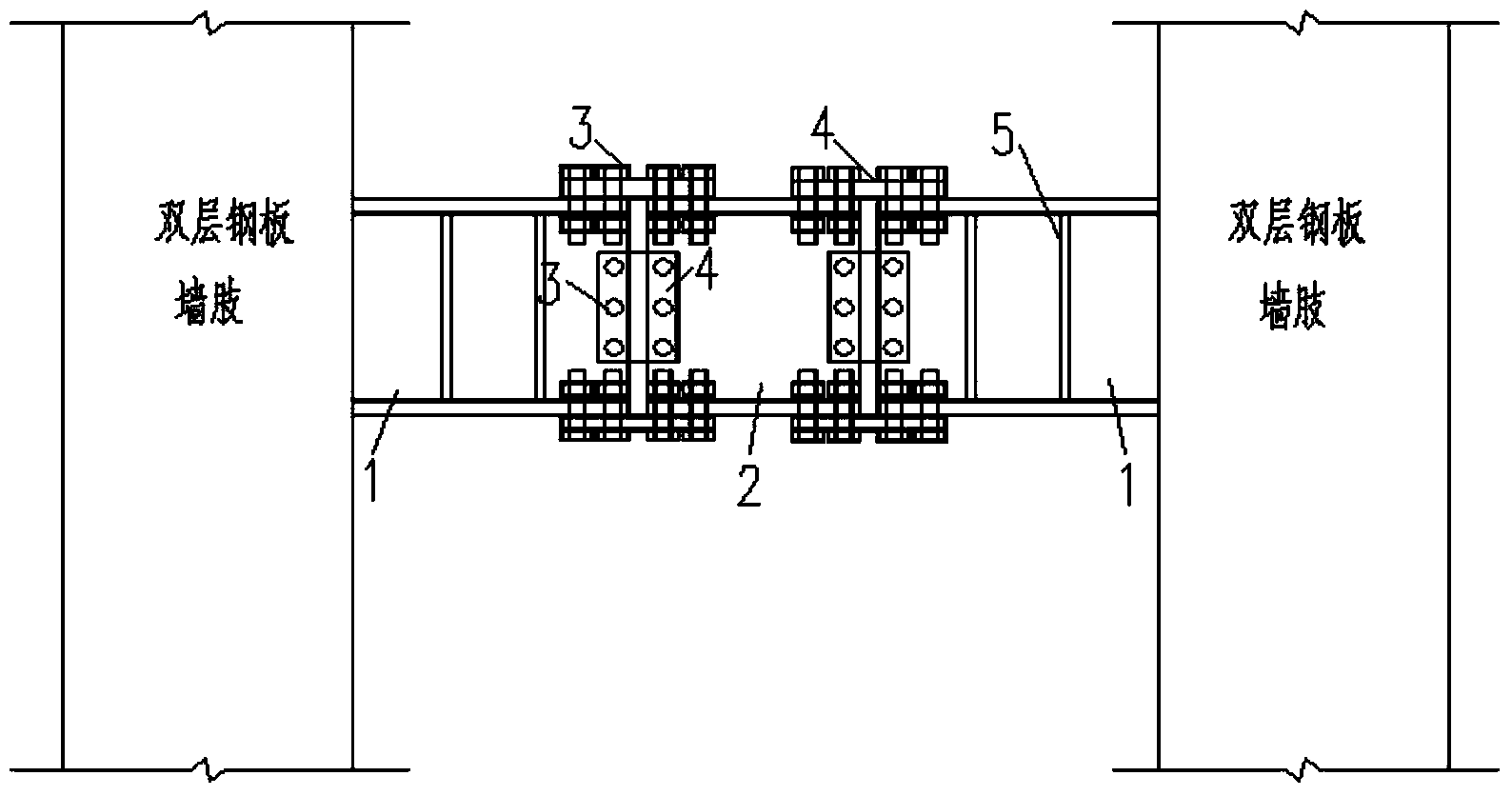

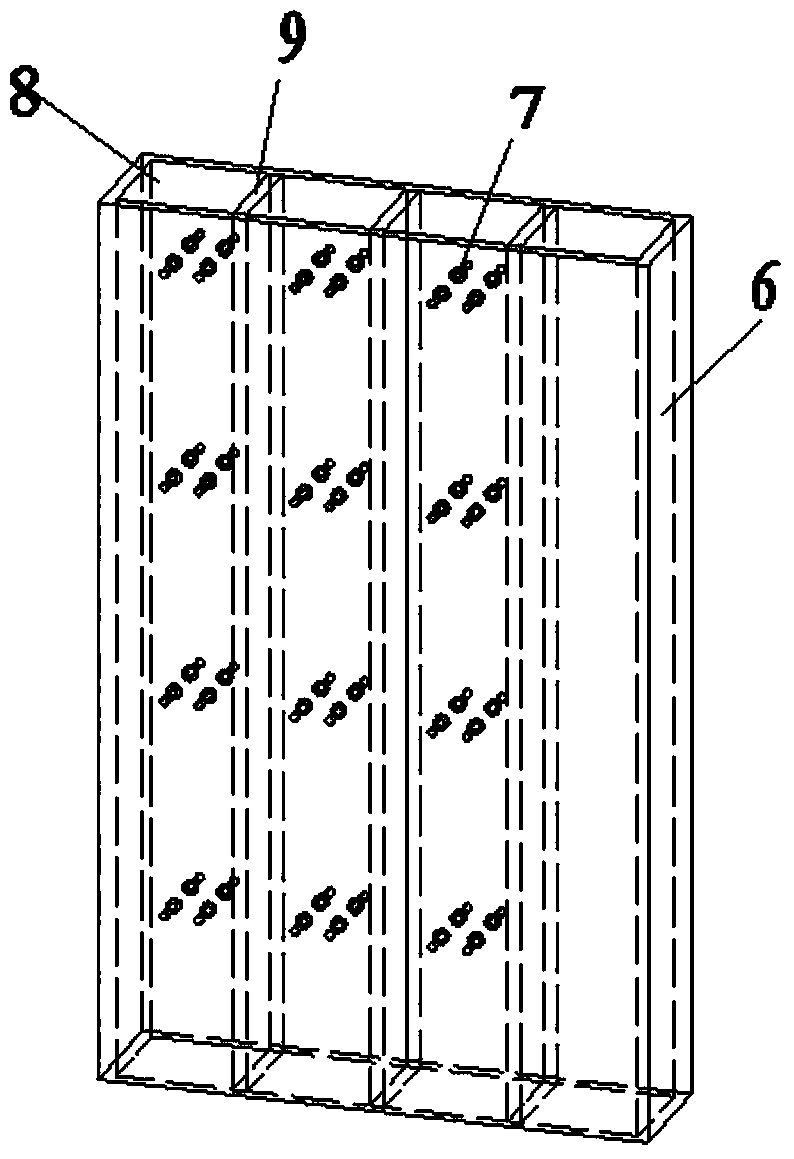

[0026] A new replaceable steel connecting beam-double-layer steel plate high-strength concrete combined shear wall, including a double-layer steel plate high-strength concrete shear wall and a replaceable steel connecting beam, which are consolidated together by welding. The high-strength concrete shear wall with double-layer steel plate includes the outer double-layer steel plate and the high-strength concrete poured between the outer double-layer steel plate. The high-strength concrete shear wall with double-layer steel plate is filled with concrete between the outer double-layer Outer double-layer steel plates are arranged on the outside of the wall; several rows of studs 7 are welded on the opposite surface of the outer double-layer steel plates 6, and the interaction between the concrete and the steel plates is enhanced by setting the studs 7 between the steel plates (such as strengthening steel plate and concrete bonding); the outsourcing double-layer steel plate is a she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com