A hook receiving seat for building installation and a building installation structure

A technology for receiving seat and installation, which is applied in the direction of building components, building structure, construction, etc. It can solve the problems of slippage, drooping of connection hole gaps, and safety hazards of de-soldering without fundamentally solving the problems, so as to save installation labor, Effect of increasing connection strength and improving installation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

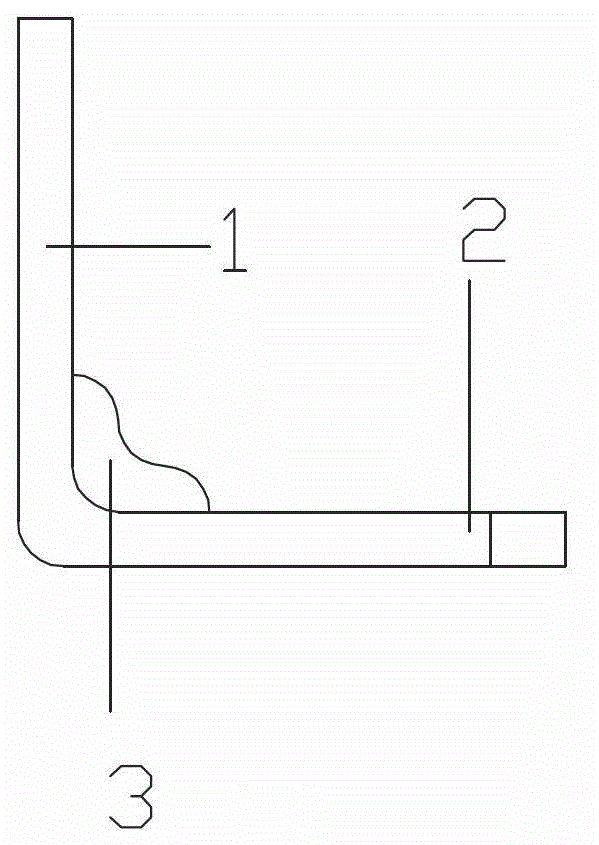

[0036]Refer to attached picture. The hook receiving seat 5a for building installation provided by the present invention is composed of a receiving plate 1 and a mounting plate 2 arranged at right angles. There is a long mounting hole 20 on the plate, and a circle of inner teeth 21 along the wall of the long mounting hole, and a concave-convex positioning configuration 22 for positioning and anti-skid is provided on the surrounding surface of the hole corresponding to the pressing part of the fastener.

[0037] There are notches 23 at both ends of the front part of the mounting plate, which correspond to the two ends of the articulated limit groove. In this way, the hook receiving seat 5a can be made of steel plate sleeves, which can save a lot of money. materials, further reducing costs.

[0038] A reinforced support structure 3 is provided between the receiving plate and the mounting plate.

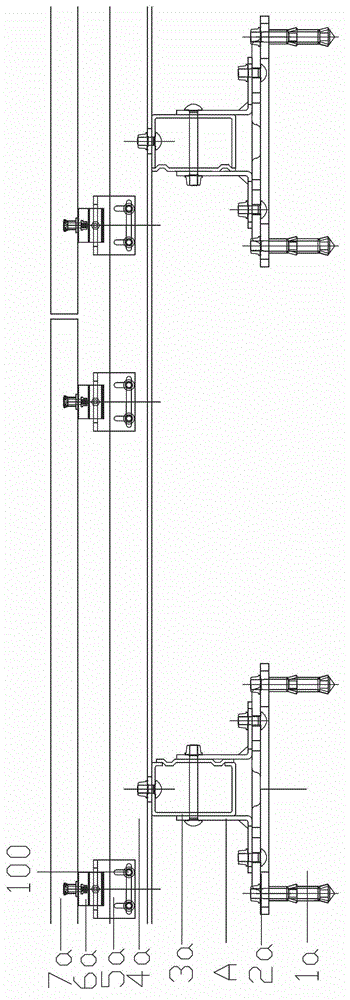

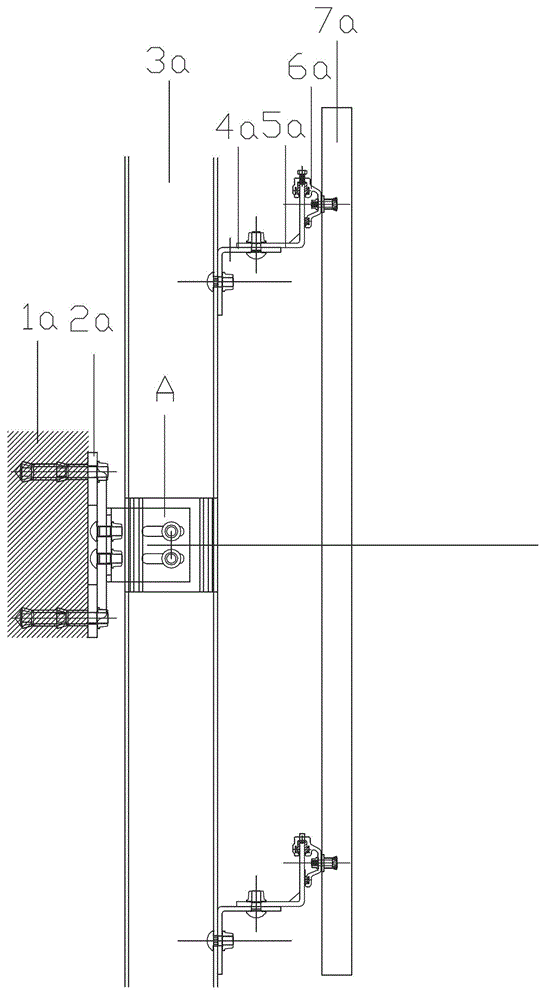

[0039] Such as figure 1 , In the curtain wall installation system shown in 2, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com