Slab for buildings as well as jointly shock-resistant assembly structure and method for wall body and slab

An assembly method and technology for construction, which are applied in the processing of building components, building structures, and building materials, can solve the problems of high cost of chemical sealants, short service life of houses, gasification of floors, etc., and save steel pipe materials and The effect of erecting workers, reducing the number of construction workers, and increasing the speed of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

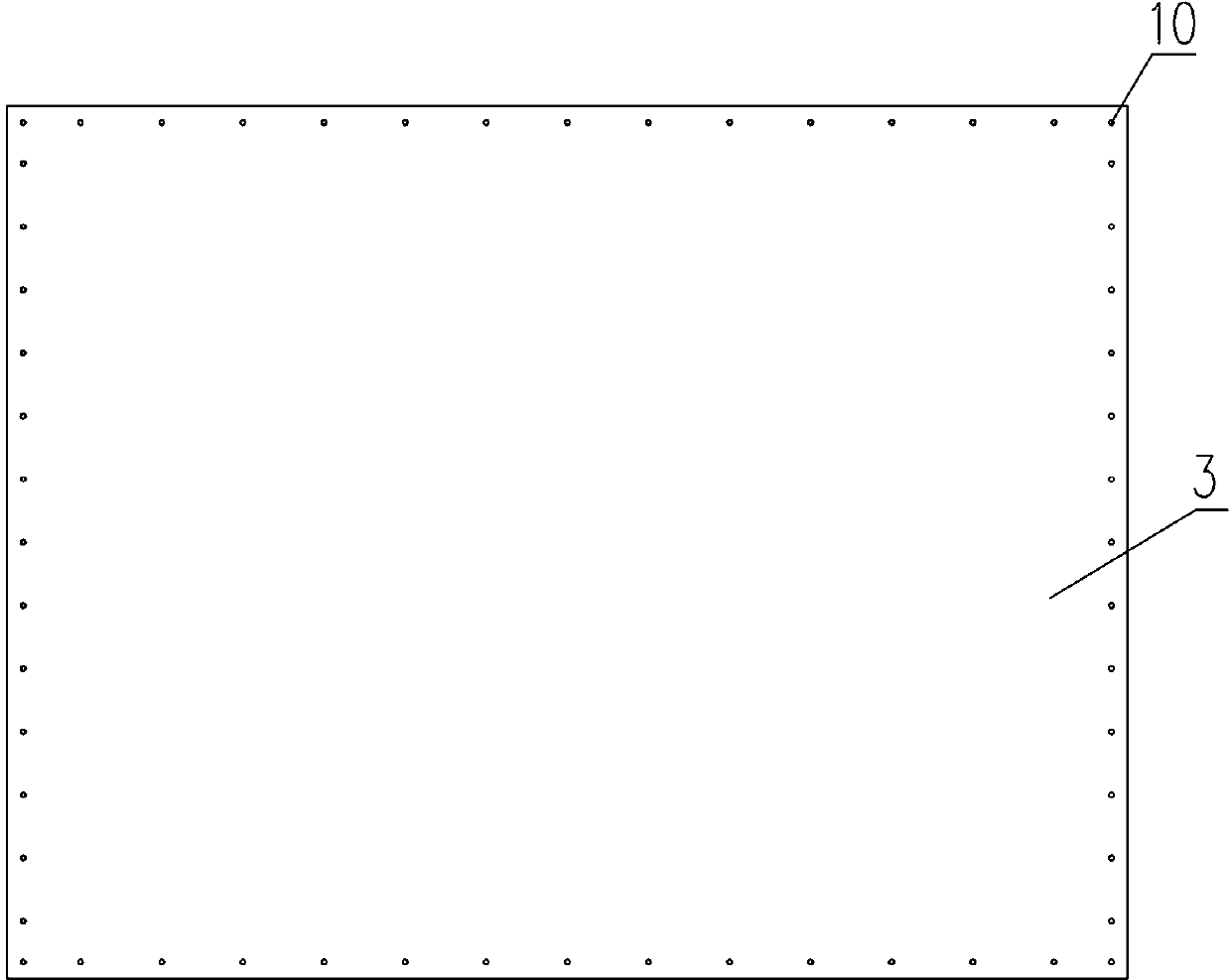

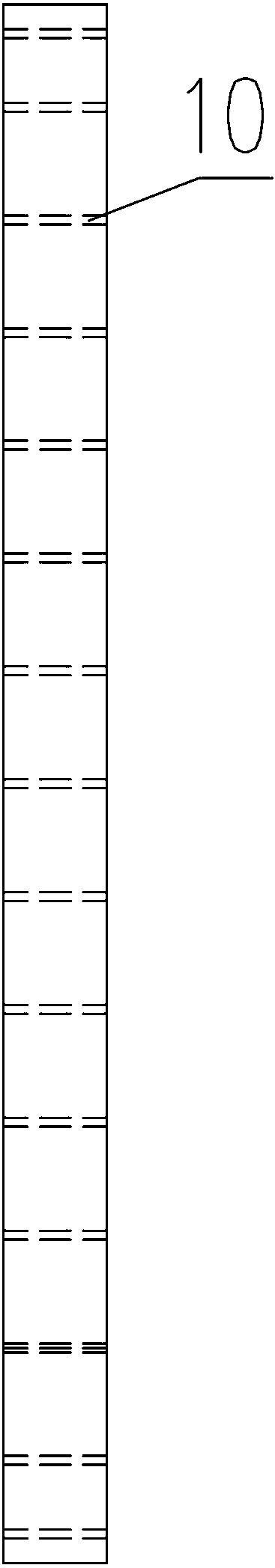

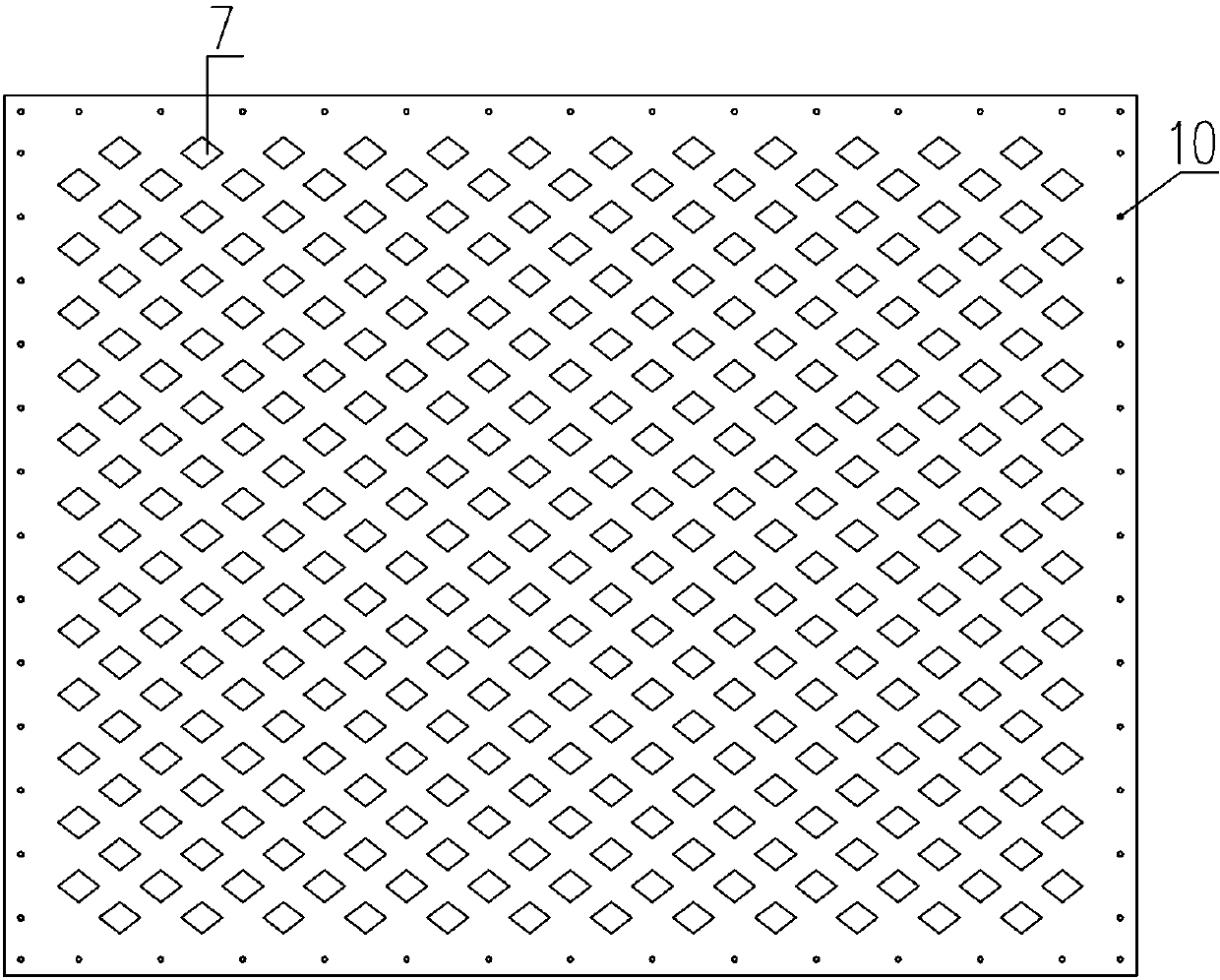

[0022] according to Figures 1 to 8 It can be seen that the floor 3 body of the present invention is prefabricated by lightweight aggregate concrete, and its size and shape are respectively consistent with the size and shape of the center line of the housing bay; one side is provided with a diamond-shaped steel mesh skeleton 5 and a honeycomb blind hole 7 formed by it; It is a flat surface formed by the invisible diamond-shaped steel mesh skeleton 5, and there are vertical bolt through holes 10 around the board surface. ; the steps include:

[0023] Place the prefabricated double-layer diamond-shaped steel mesh skeleton 5 on the horizontal vibrating mold platform, and pour the mixed concrete with quick-drying special cement, fireproof lightweight aggregate and river sand filler on the mold platform, and then vibrate and release the mold for curing Forming, and then on the interlocking hollow or blind hole brick or ring beam block wall, the whole floor slab 3 is transported to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com