Waste heat recovery energy-saving device adapted to boiler chimney and chimney including the device

A waste heat recovery and energy-saving device technology, applied in the field of chimneys, can solve the problems of reducing the life of heat exchange tubes and boilers, reducing the heat transfer efficiency of heat exchange tubes, affecting the efficiency of waste heat recovery in the chimney, etc. Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

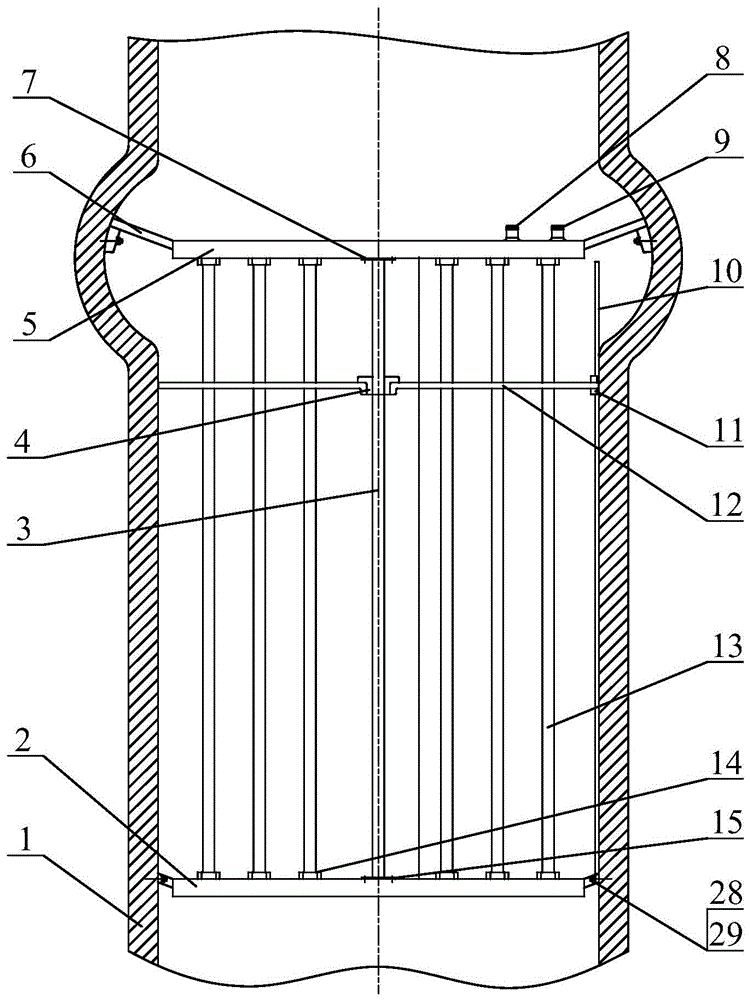

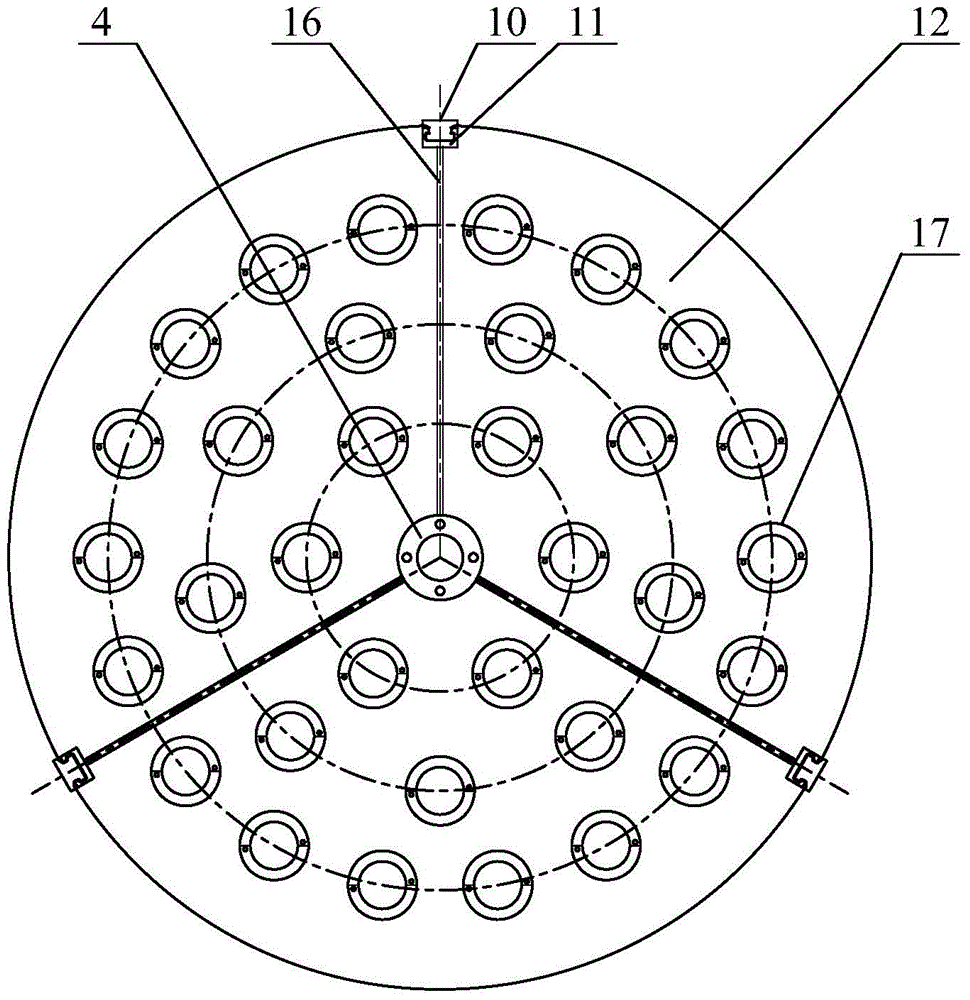

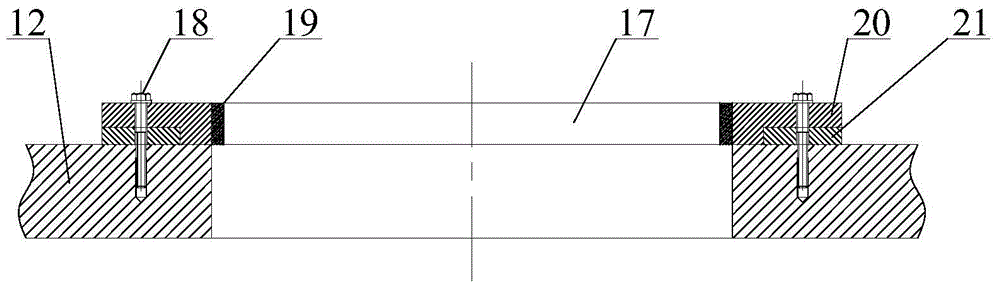

[0022] combine Figure 1~4 , the energy-saving part is the core part of the device, mainly composed of a boiler 23, an air outlet 27, a chimney 1, an inspection port 26, a heat exchange tube 13, an inner wire pipe joint 14, a lower guide ring 2, an upper guide ring 5, an inlet Water outlet 8, water outlet 9, connecting plate 6, connecting plate 28, expansion screw 29, fan 22; Expansion screw 29 is installed in the chimney close to chimney 1 and gas outlet 27 joints, and the position design an inspection hole 26 is installed energy-saving device on chimney. A blower fan 22 is installed at the air inlet of the boiler, which can not only enable the fuel to be fully burned in the boiler but also increase the pressure of the gas at the air outlet to provide greater power for the movement of the sealing disc 12 . When installing the energy-saving device, insert a plur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com