Heat pump drying equipment

A heat pump drying and equipment technology, applied in drying, lighting and heating equipment, dryers and other directions, can solve the problems of aggravated fuel air pollution, high use cost, increased burden on farmers, etc., and achieve good social benefits and use costs. Outstanding effect of saving and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

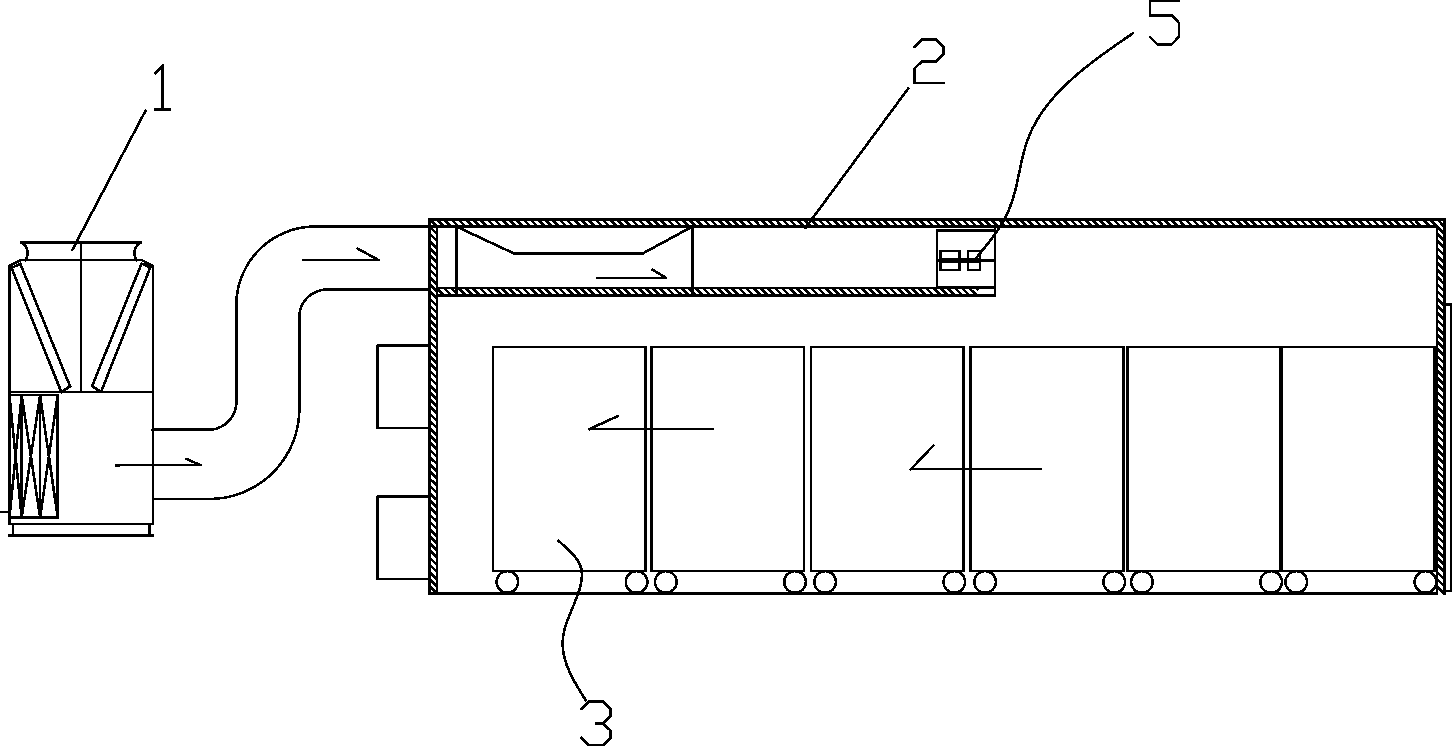

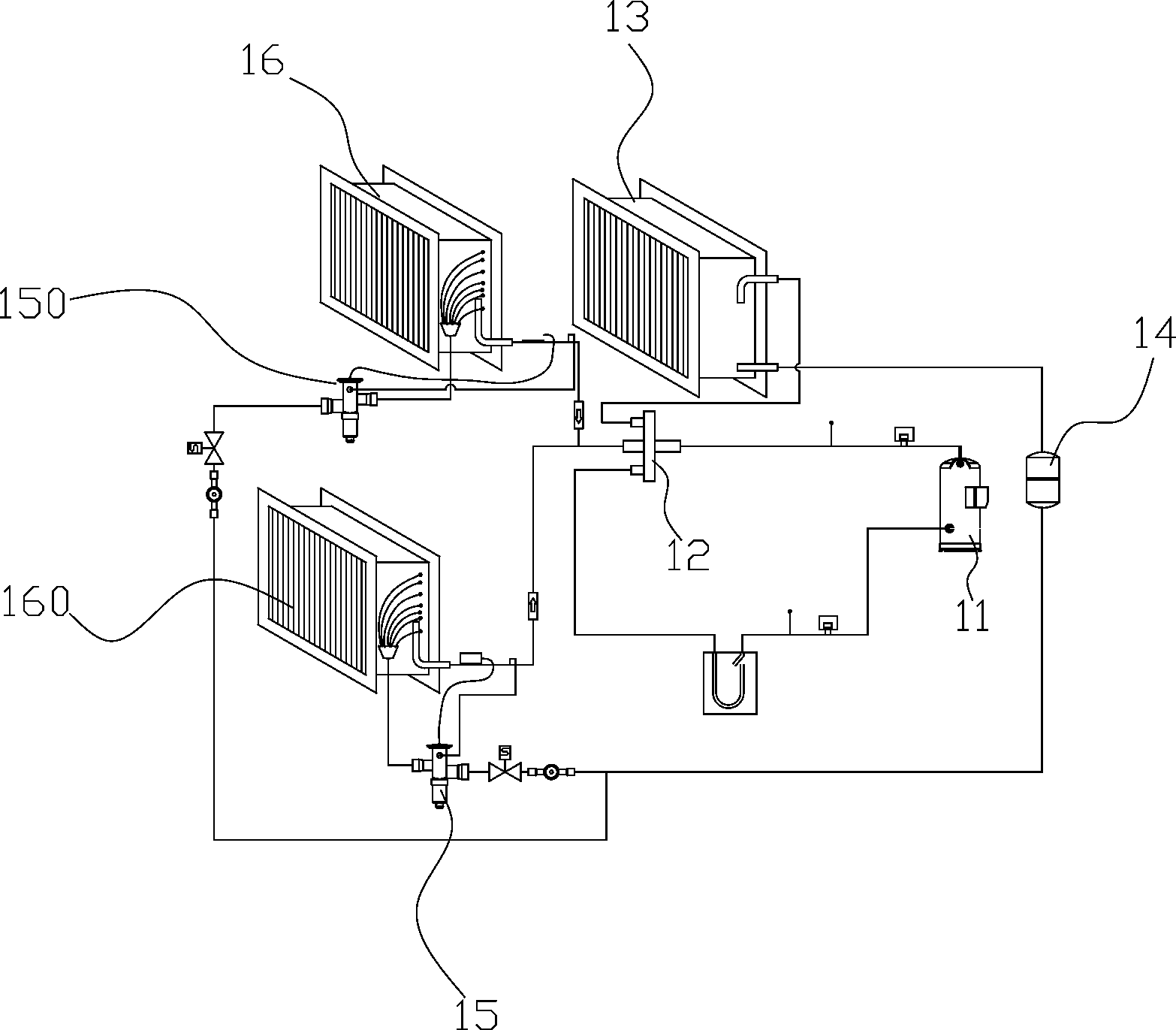

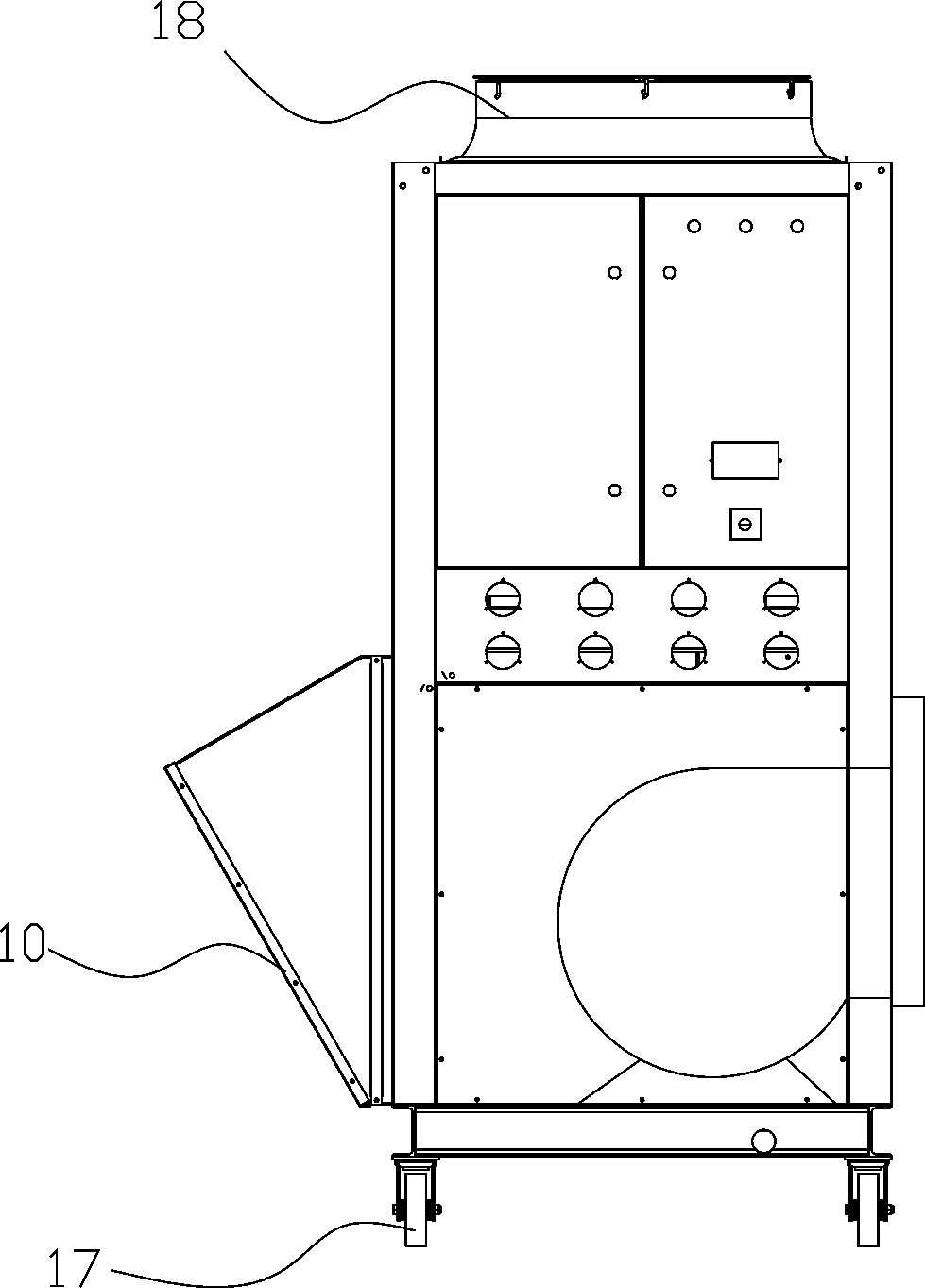

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 3 , heat pump drying equipment, including a heat pump drying unit 1 and a drying tower 2 connected to the heat pump drying unit 1, the heat pump drying unit includes an air inlet 10, and the heat pump drying unit 1 includes an air dehumidification circuit , the air dehumidification loop includes a compressor 11, a four-way valve 12, a condenser 13, a dry filter 14, a first thermal expansion valve 15, and a dehumidification heat exchanger 16 connected in sequence, and the dehumidification heat exchanger 16 is connected to The four-way valve 12, the heat pump drying unit 1 also includes an air circulation pipeline and at least one refrigerant circulation circuit, and the refrigerant circulation circuit includes a compressor 11, a four-way valve 12, a condenser 13, a dry filter 14, the second thermal expansion valve 150, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com