Pressure-broadening-based alkali metal stream atomic density measuring method

A technology of atomic density and measurement method, applied in measurement devices, specific gravity measurement, instruments, etc., can solve the problems of complex experiments, narrow curve line width, large errors, etc., to achieve the effect of simple and reliable method and avoid density measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

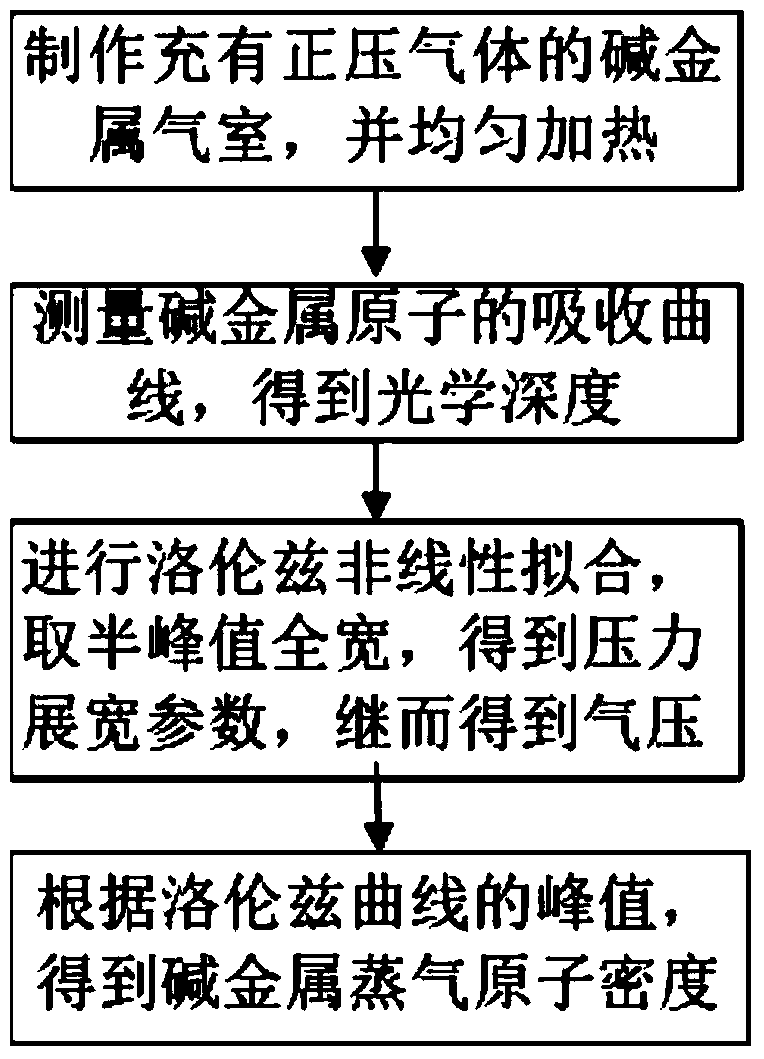

[0020] Such as figure 1 Shown, the specific implementation steps of the present invention are as follows:

[0021] 1. Make a glass air chamber containing alkali metal and a vacuum air chamber filled with positive pressure gas and vacuum conditions, and heat it evenly with an oven.

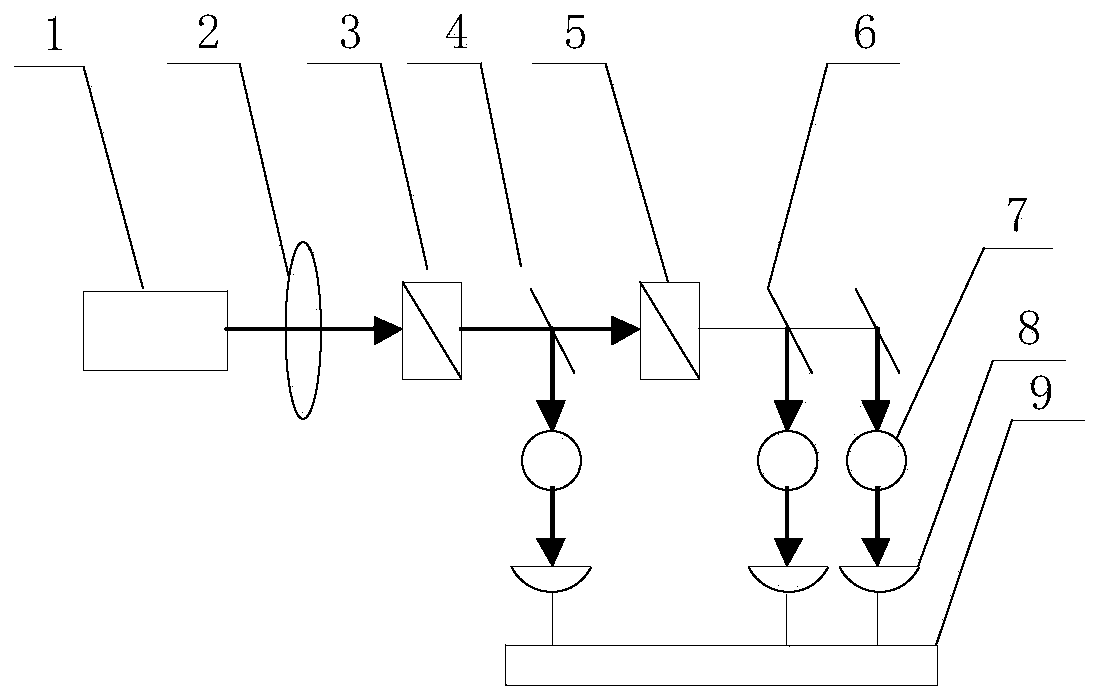

[0022] 2. Put the glass air chamber made in step 1 in such as figure 2 In the experimental device shown, 1 is a DFB laser, 2 is a collimator lens, 3 and 5 are 1 / 2 wave plates, 4 and 6 are PBS, 7 is a glass air chamber, and the 3 in the figure are vacuum air chambers. Chamber, vacuum alkali metal gas chamber, alkali metal gas chamber filled with positive pressure gas, 8 is a photodetector, and 9 is a data acquisition board.

[0023] The gas chamber is irradiated with a laser with a stable power and the frequency is swept, and the absorption curve of the alkali metal is measured. The specific steps are:

[0024] 1) Pass the laser twice through the beam splitting prism and divide it into three be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com