Method for etching silicide-blocked oxide layer

A technology for blocking oxides and silicides, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem that the thickness and uniformity of the remaining silicide blocking oxide layer cannot be well controlled Etch speed and etch uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

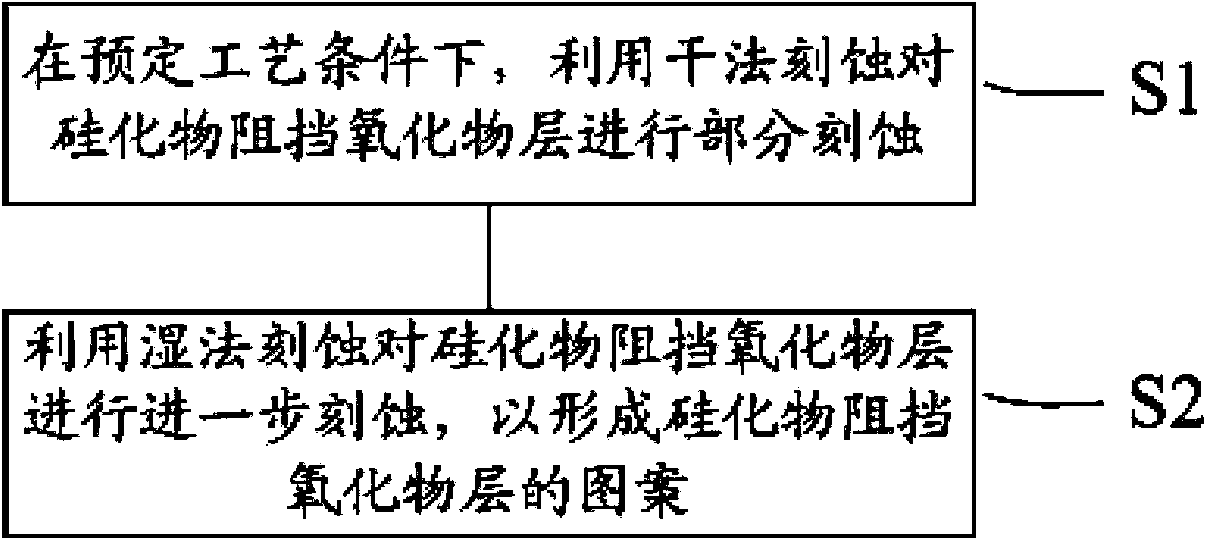

[0024] figure 1 A flow chart of a method for etching a silicide blocking oxide layer according to a preferred embodiment of the present invention is schematically shown.

[0025] The method is particularly suitable for etching silicide blocking oxide layers with a total thickness of 300-400A. Therefore, in this embodiment, the total thickness of the selective silicide blocking oxide layer is 300-400 Å.

[0026] Specifically, as figure 1 As shown, the etching method for the silicide blocking oxide layer according to the preferred embodiment of the present invention includes:

[0027] The first etching step S1: performing partial etching on the silicide blocking oxide layer by dry etching under predetermined process conditions;

[0028] Prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com