A Microstructure Plasma Device Based on Printed Circuit Board Technology

A technology for printed circuit boards and ion devices, which is applied in the directions of plasma and electrical components, and achieves the effects of less process links, simple and feasible process, and extremely easy production and production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below.

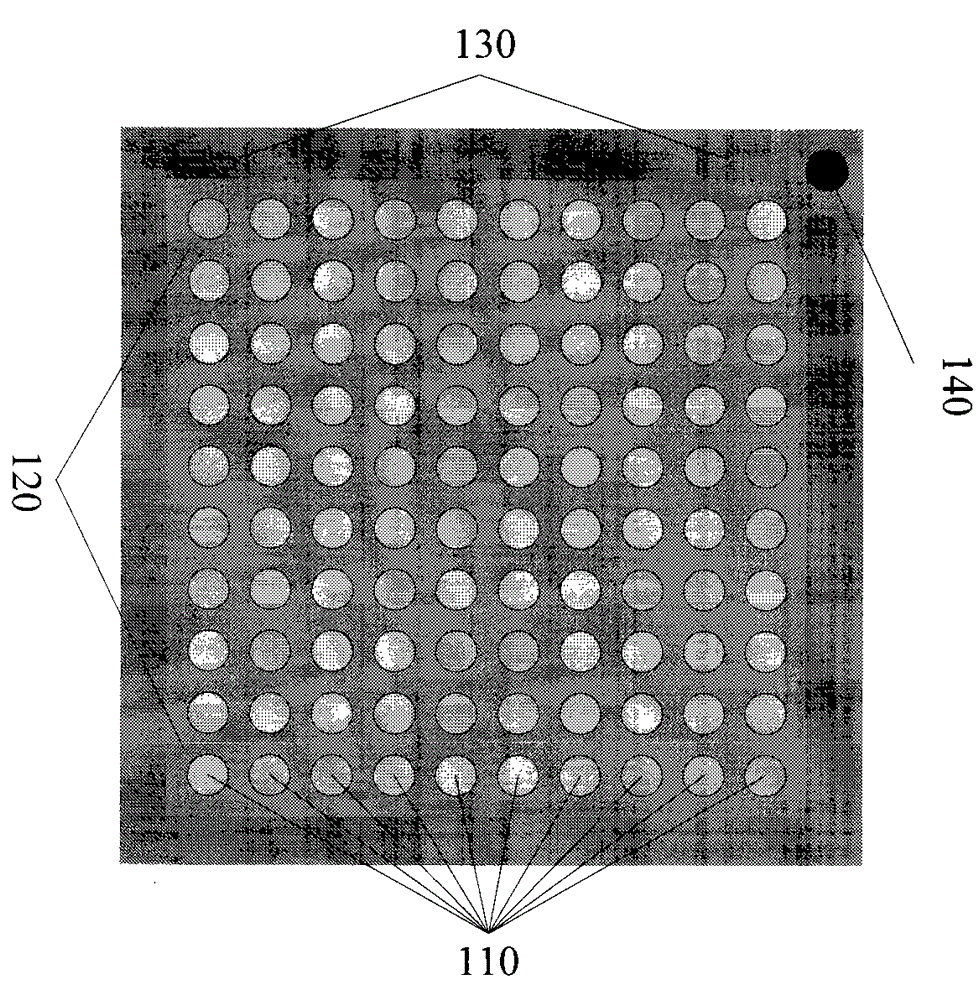

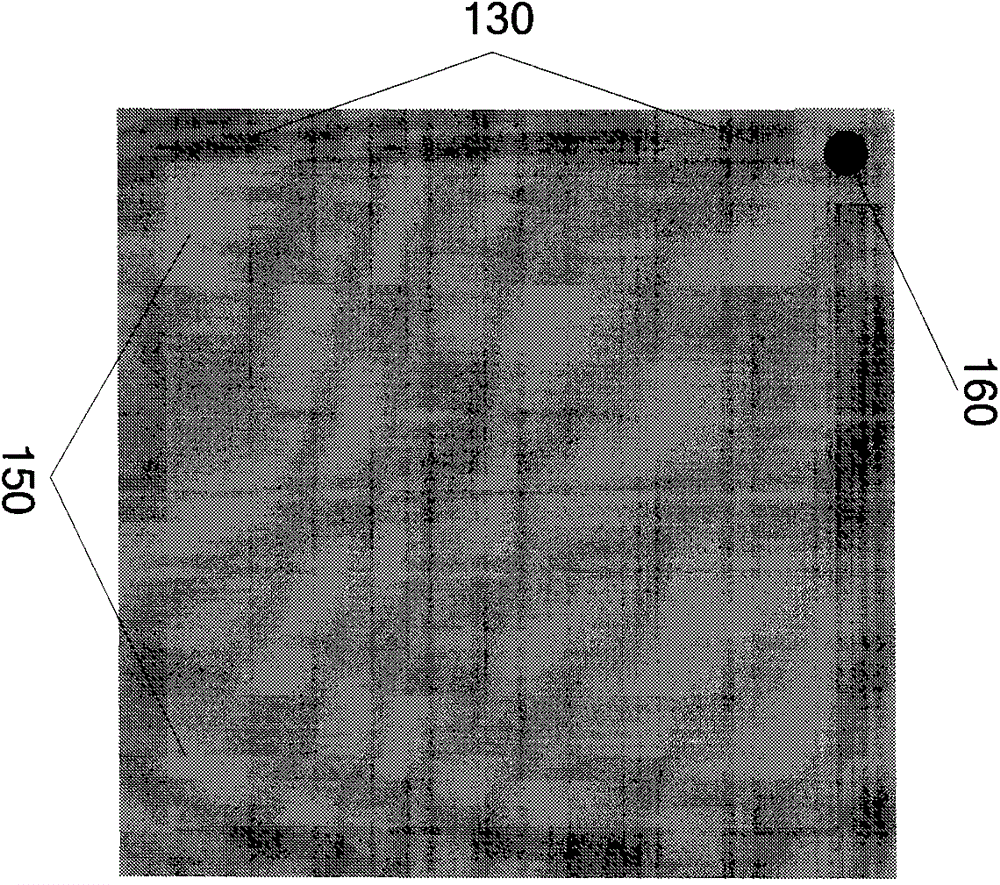

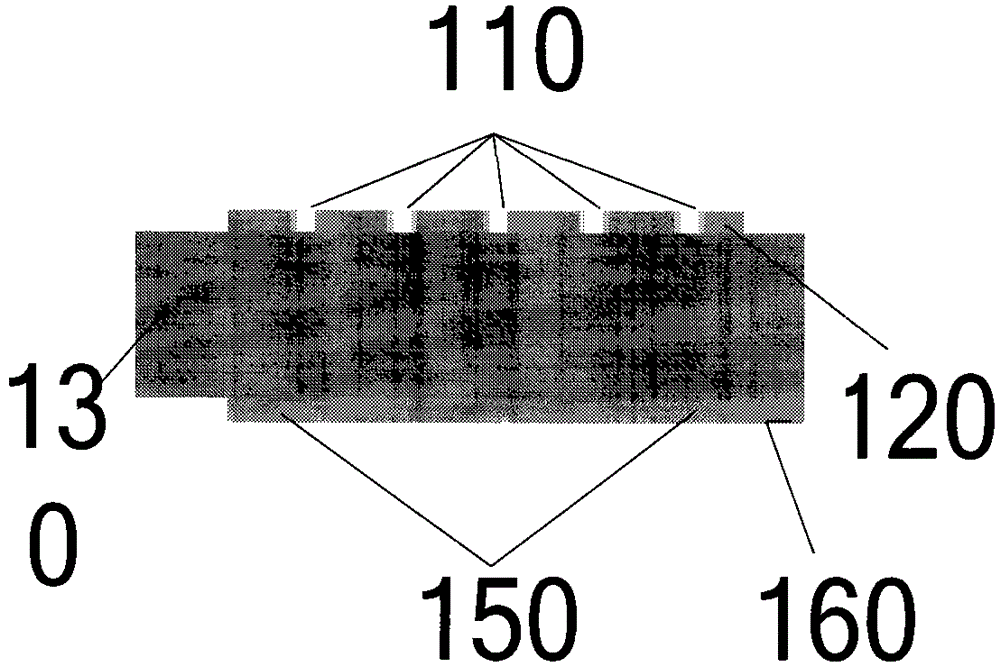

[0023] The device microcavity is composed of an upper electrode, an intermediate dielectric layer and a lower electrode, and each unit of the device is driven by the upper and lower electrodes. Take the insulating dielectric epoxy resin material as the base, make two layers of copper foil on the upper and lower surfaces of the base, leaving a certain safe distance between the edge of the copper foil and the edge of the base. Cylindrical microcavity semi-through holes (just pass through the upper electrode but not the middle dielectric layer and the lower electrode) units are arranged in an array, and the distance between rows in the array is not less than the distance between columns. The upper and lower layers of copper foil separated by the bottom plate are used as the upper and lower electrodes, and the two electrodes are respectively led out of the connection terminals, thus obtaining a coplanar microst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com