Graphitized cathode block having an abrasion-roof surface

A cathode block and graphitization technology, applied in the field of cathode blocks, can solve the problems of fragile coating, short service life, easy cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

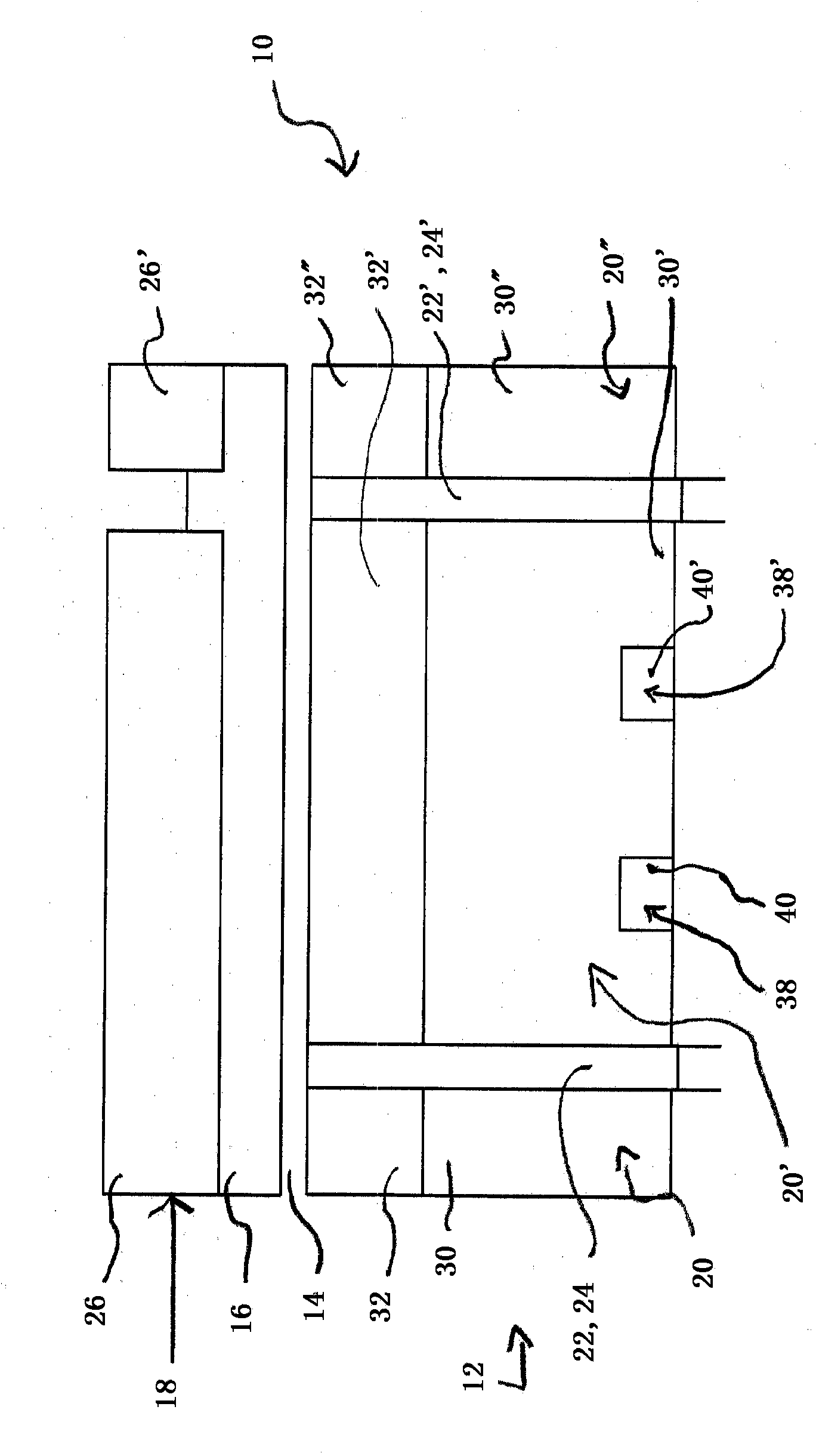

[0057] figure 1 A cross section showing details of an aluminum electrolytic cell 10 with a cathode 12 simultaneously forming the bottom of a tank for the aluminum melt 14 produced during operation of the electrolytic cell 10 and for the Cryolite-alumina melt 16 above aluminum melt 14 . The anode 18 of the electrolytic cell 10 is in contact with the cryolite-alumina melt 16 . The tank formed by the lower part of the aluminum electrolysis cell 10 is lined at the sides with carbon and / or graphite (at figure 1 not shown) defined.

[0058] The cathode 12 comprises a plurality of cathode blocks 20, 20', 20'' which are each connected to each other by ramming materials 24, 24' which have been inserted into the , 20'' between the ramming material joints 22, 22'. Similarly, the anode 18 includes a plurality of anode blocks 26 , 26 ′ each having approximately twice the width and approximately half the length of the cathode blocks 20 , 20 ′, 20 ″. In this case, the anode blocks 26 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com