Acoustic generator and acoustic generation device using same

A sound generator and speaker technology, applied in microphones, frequency/directional characteristic devices, piezoelectric/electrostrictive transducer microphones, etc., can solve the problem of generating large peaks or troughs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment )

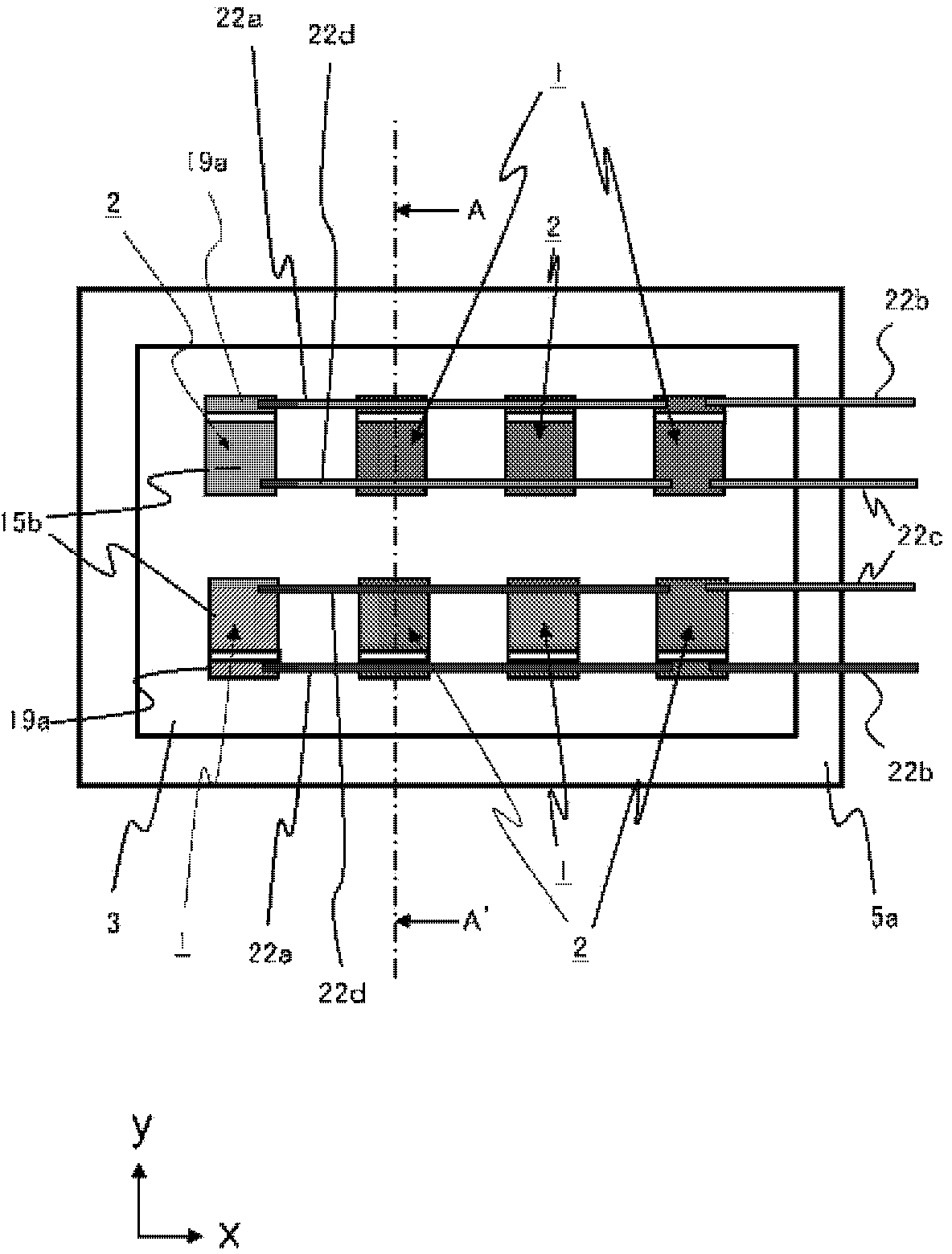

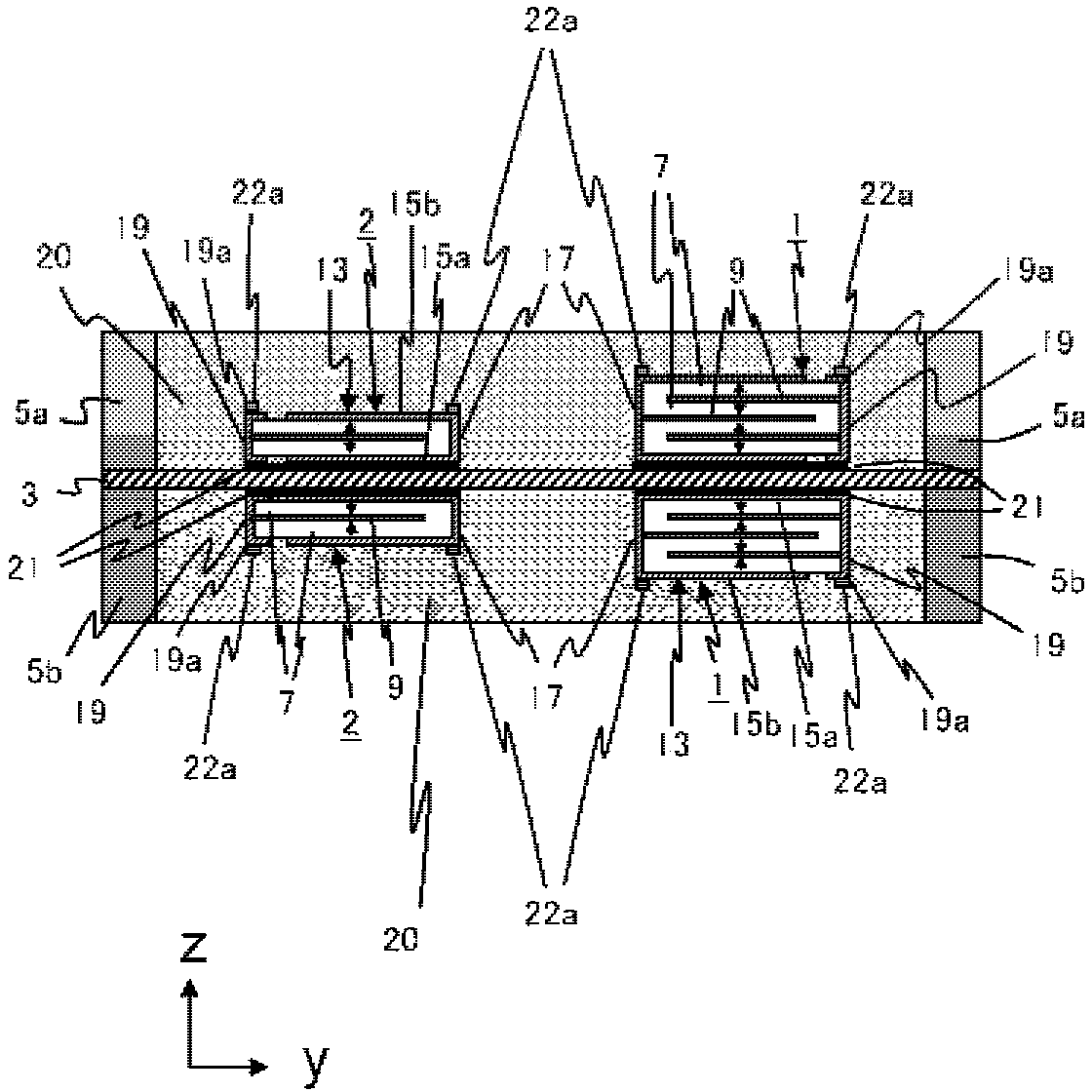

[0092] A specific example of the acoustic generator of the present invention will be described. make figure 1 , 2 The acoustic generator of the first example of the embodiment of the present invention was shown, and its electrical characteristics were measured.

[0093] First, the piezoelectric powder containing lead zirconate titanate (PZT) in which part of Zr was substituted with Sb, binder, dispersant, plasticizer, and solvent was mixed by ball milling for 24 hours to prepare a slurry . Then, using the obtained slurry, a green sheet was produced by a doctor blade method. On this green sheet, a conductor paste containing Ag and Pd as an electrode material was applied in a predetermined shape by a screen printing method. Then, the green sheet coated with the conductor paste and the green sheet not coated with the conductor paste are laminated and pressed to produce a laminated molded body. Then, this laminated molded body was degreased in the air at 500° C. for 1 hour, a...

no. 2 Embodiment )

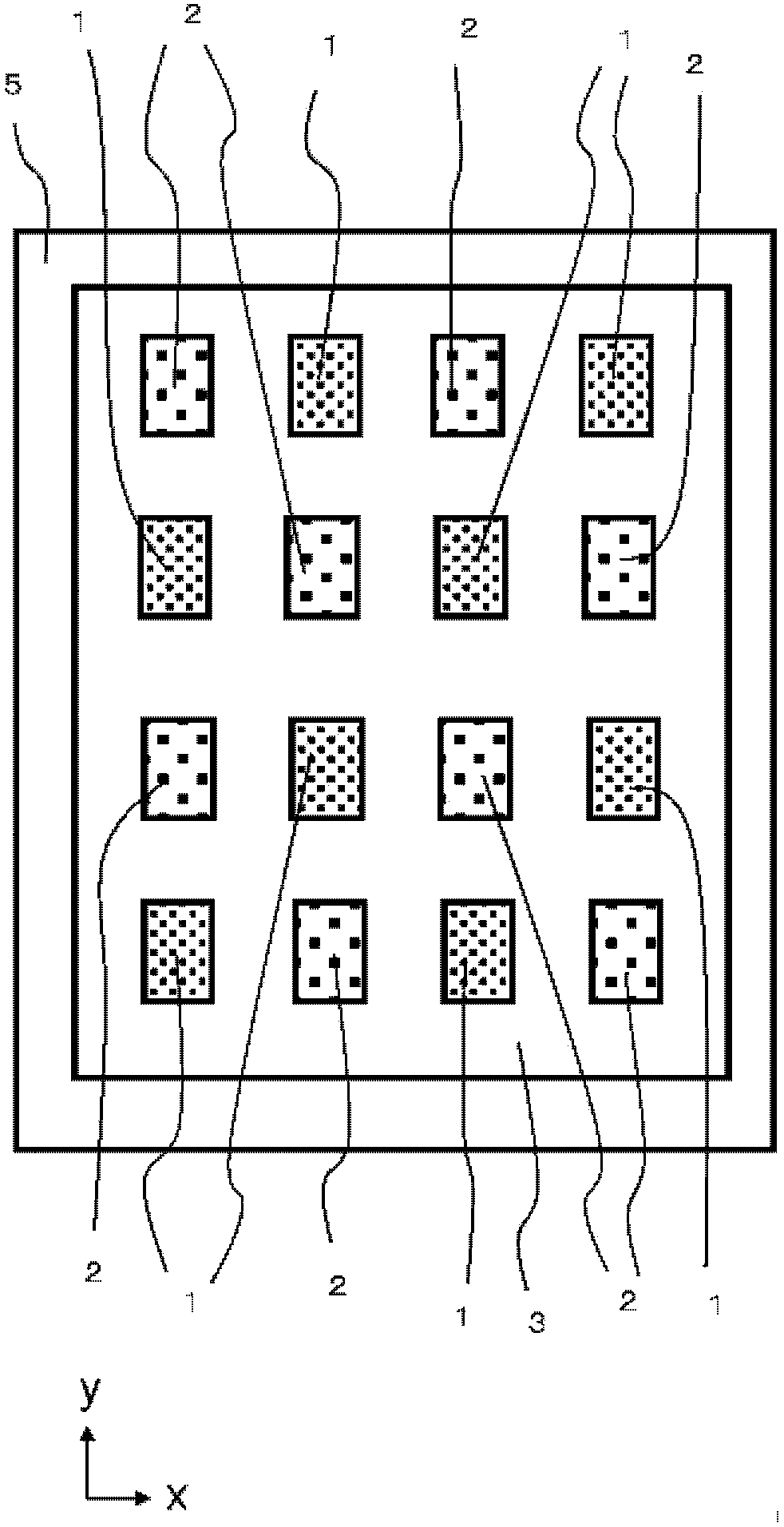

[0101] about Figure 5the acoustic generator of the fourth example of the illustrated embodiment, and Figure 9 In the acoustic generator of the second comparative example shown, the number of eigenvalues of vibration (the number of vibration modes) affecting the sound pressure characteristics was calculated by simulation. in addition, Figure 5 the acoustic generator of the fourth example of the illustrated embodiment, and Figure 9 The acoustic generator of the second comparative example shown differs only in how the piezoelectric elements 1 and 2 are arranged. which is, Figure 5 In the acoustic generator of the fourth example of the illustrated embodiment, two types of acoustic generators having different thicknesses are arranged in each of two directions intersecting each other (the x-axis direction and the y-axis direction in the drawing in directions orthogonal to each other). Piezoelectric elements (Piezoelectric elements 1, 2). in comparison, Figure 9 In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com