Production-line type plant factory implementation method based on plant growth characteristics and rhythm

A plant growth and assembly line technology, applied in botany equipment and methods, horticulture, application, etc., can solve the problem that the greenhouse environment is difficult to achieve crop growth environment, it is difficult to achieve large-scale, industrialized promotion, and it is impossible to form a standardized process, etc. problems, to achieve the effect of easy large-scale promotion, short cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

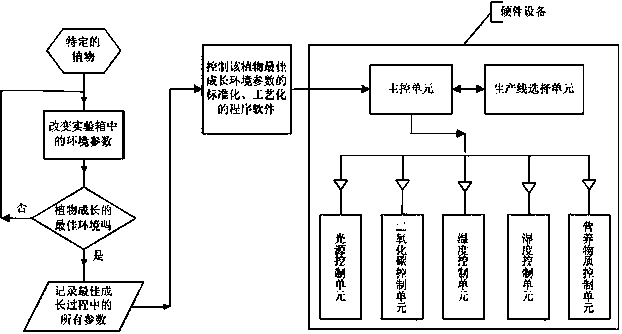

[0023] The invention relates to a low-cost, specific, refined, standardized and programmed "assembly line" plant factory based on the growth characteristics and laws of plants. The present invention will be further described below in conjunction with accompanying drawing.

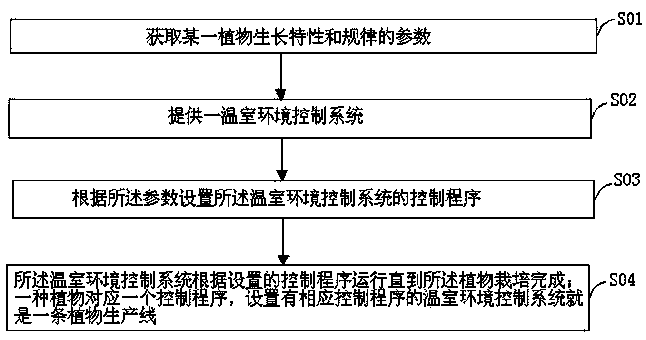

[0024] Such as figure 1 As shown, the present embodiment provides a method for realizing an assembly line plant factory based on plant growth characteristics and laws, which is characterized in that it includes the following steps:

[0025] Step S01: Acquiring parameters of certain plant growth characteristics and regularity;

[0026] Step S02: providing a greenhouse environment control system;

[0027] Step S03: setting the control program of the greenhouse environment control system according to the parameters;

[0028] Step S04: The greenhouse environment control system runs according to the set control program until the cultivation of the plants is completed; one type of plant corresponds to one cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com