Reinforced desulphurization method and reinforced desulphurization system of desulphurizer for combustion system of circulating fluidized bed

A circulating fluidized bed and combustion system technology, which is applied to fluidized bed combustion equipment, combustion methods, and fuels burned in a molten state, can solve problems such as low desulfurization efficiency and low utilization efficiency of desulfurizers, reduce system complexity, and improve efficiency. Conducive to the effect of large-scale and low-pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

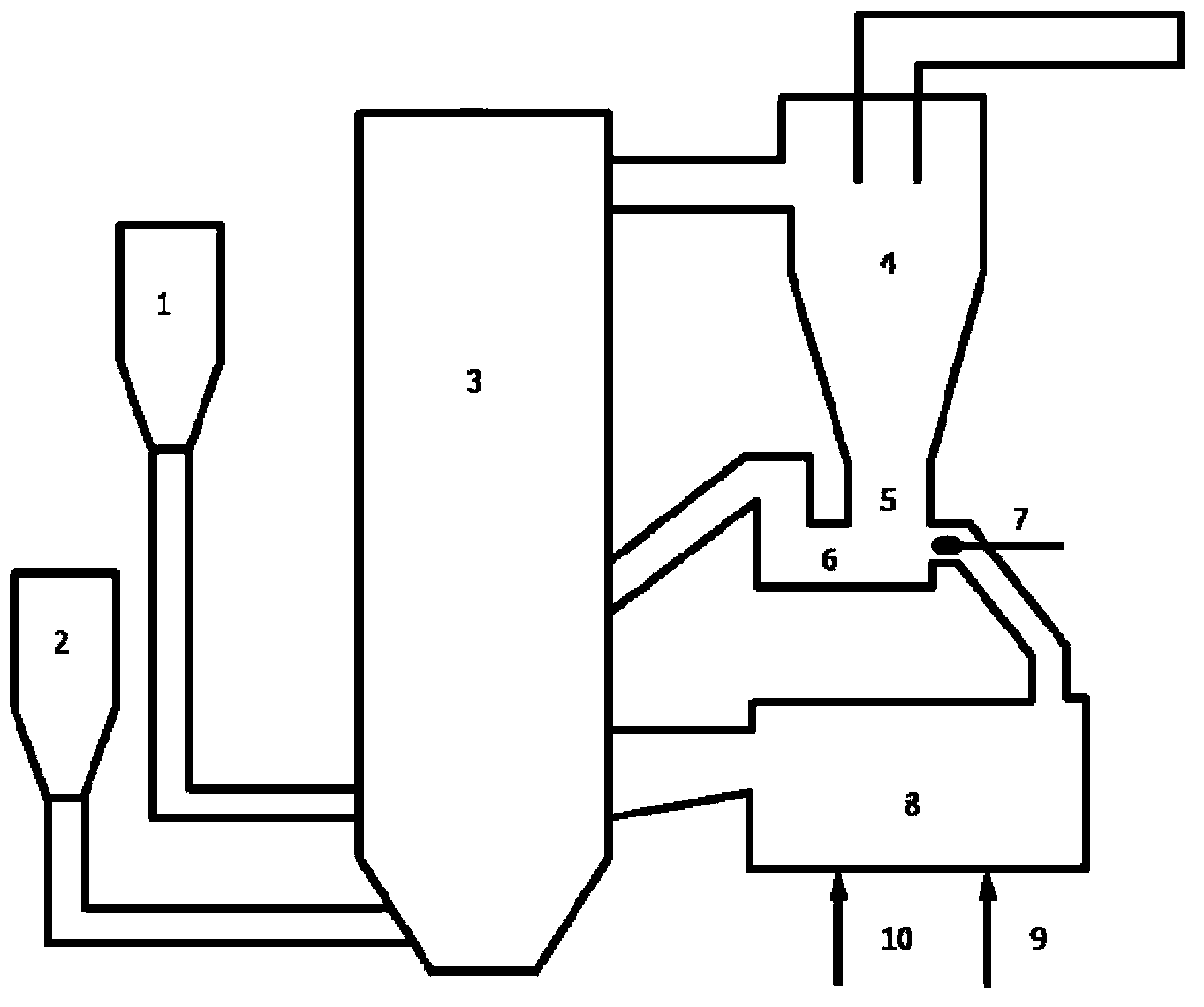

[0020] Referring to the attached picture:

[0021] A method for strengthening desulfurization by a desulfurizer in a circulating fluidized bed combustion system, comprising the following steps:

[0022] Step 1, the desulfurizer absorbs SO in the flue gas in the combustion chamber (3) 2 ;

[0023] Step 2, circulating ash separation: the unreacted CaO in the circulating ash is carried by the flue gas into the gas-solid separator (4) for circulating ash separation;

[0024] Step 3, distribution of circulating ash: After separation, the circulating ash falls into the feeder (6), a part of the circulating ash in the feeder (6) is directly sent back to the combustion chamber, and the other part enters the activation regeneration chamber (8);

[0025] Step 4, recycling ash regeneration, pass water vapor and carbon dioxide gas into the activation regeneration chamber (8), activate the unreacted CaO in the recycling ash, and generate Ca(OH) 2 , while passing a high concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com