A pulsed water jet inhalation atomization device

A technology of atomization device and water jet, which is applied in the direction of injection device and liquid injection device, can solve the problems of high energy consumption and complex structure, and achieve the effects of low energy consumption, enhanced cavitation and impact ability, and obvious energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

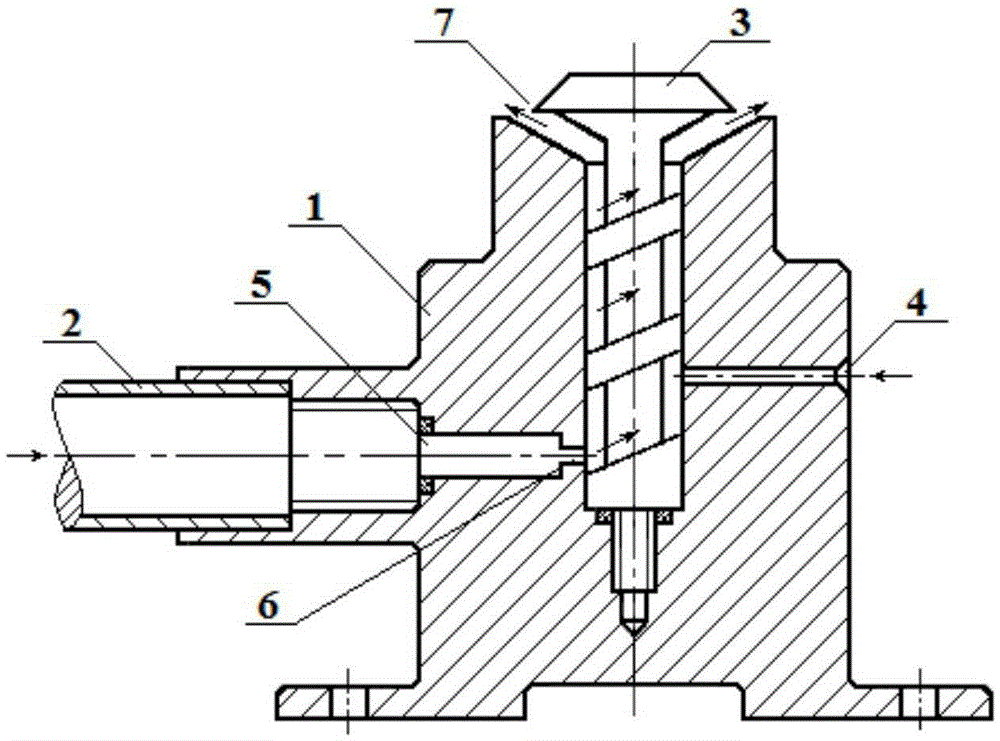

[0010] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

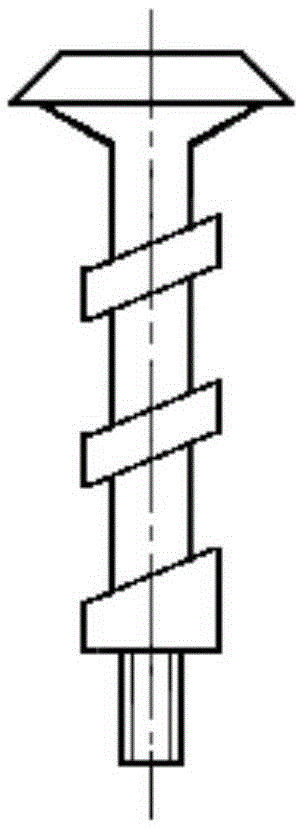

[0011] The pulse water jet inhalation atomization device of the present invention is mainly composed of a valve seat 1 , a water inlet joint 2 and a nozzle spiral column 3 . There is a central stepped blind hole in the middle of the valve seat 1, and the orifice of the central stepped blind hole is a bell mouth. The central stepped blind hole is provided with a nozzle spiral column 3 that cooperates with its inner wall to form a spiral flow channel. The nozzle spiral column 3 The tail is in the shape of a trumpet, and is matched with the trumpet mouth of the central stepped blind hole to form an annular spout 7, and the distance between the annular spouts 7 is 0.5-2mm. The spiral column 3 of the nozzle adopts a spiral groove structure, cooperates with the inner wall surface of the valve seat 1 to form a spiral flow channel, and guides the mixing of water an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com