Zipper puller automatic paint spraying device

An automatic painting and zipper head technology, applied in coatings, devices for coating liquid on the surface, etc., can solve the problems of high labor intensity for operators to carry, unsatisfactory product pass rate, difficult to control product quality, etc., and achieve automation Easy to operate, easy to ensure the effect of spray painting, and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

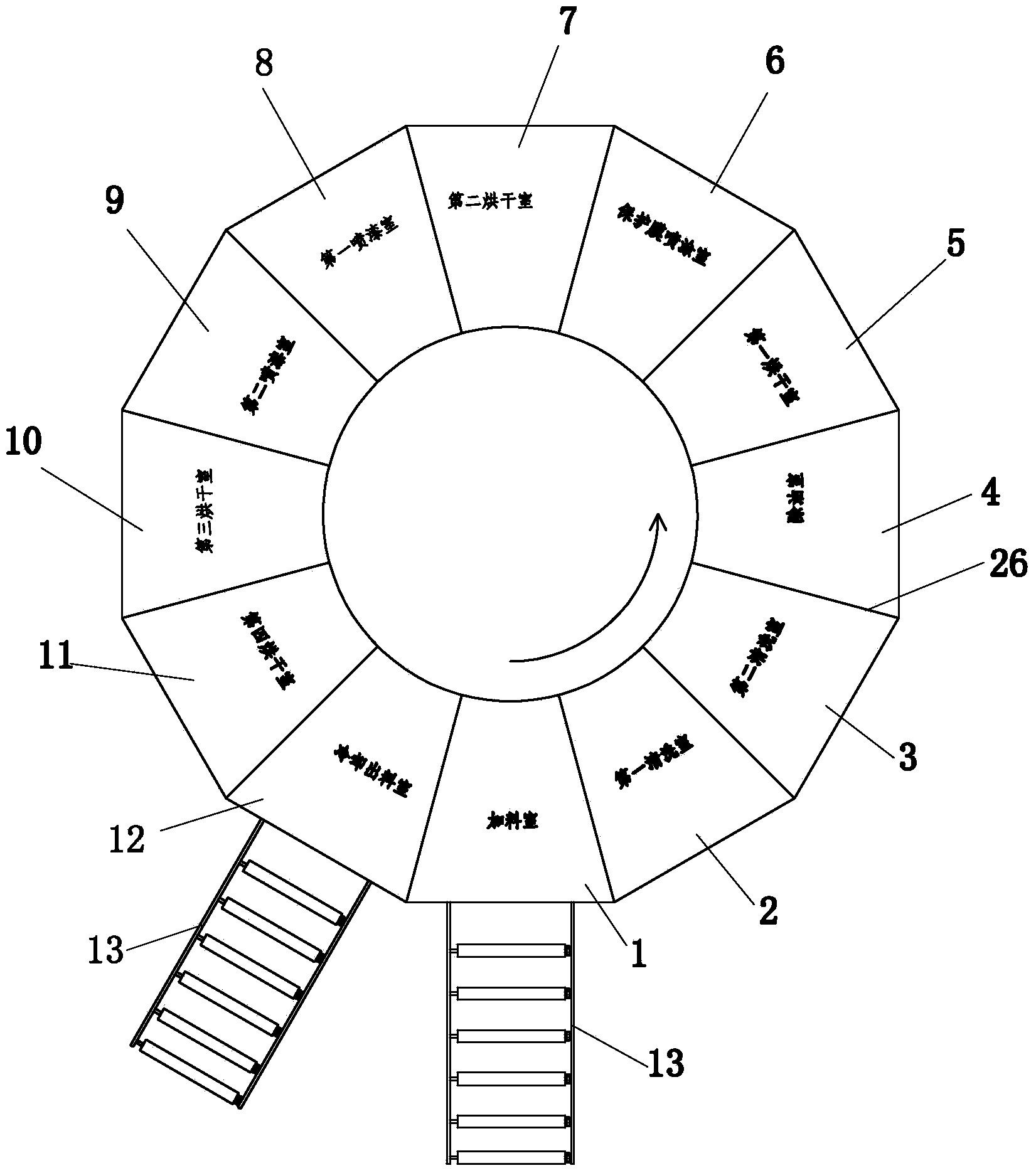

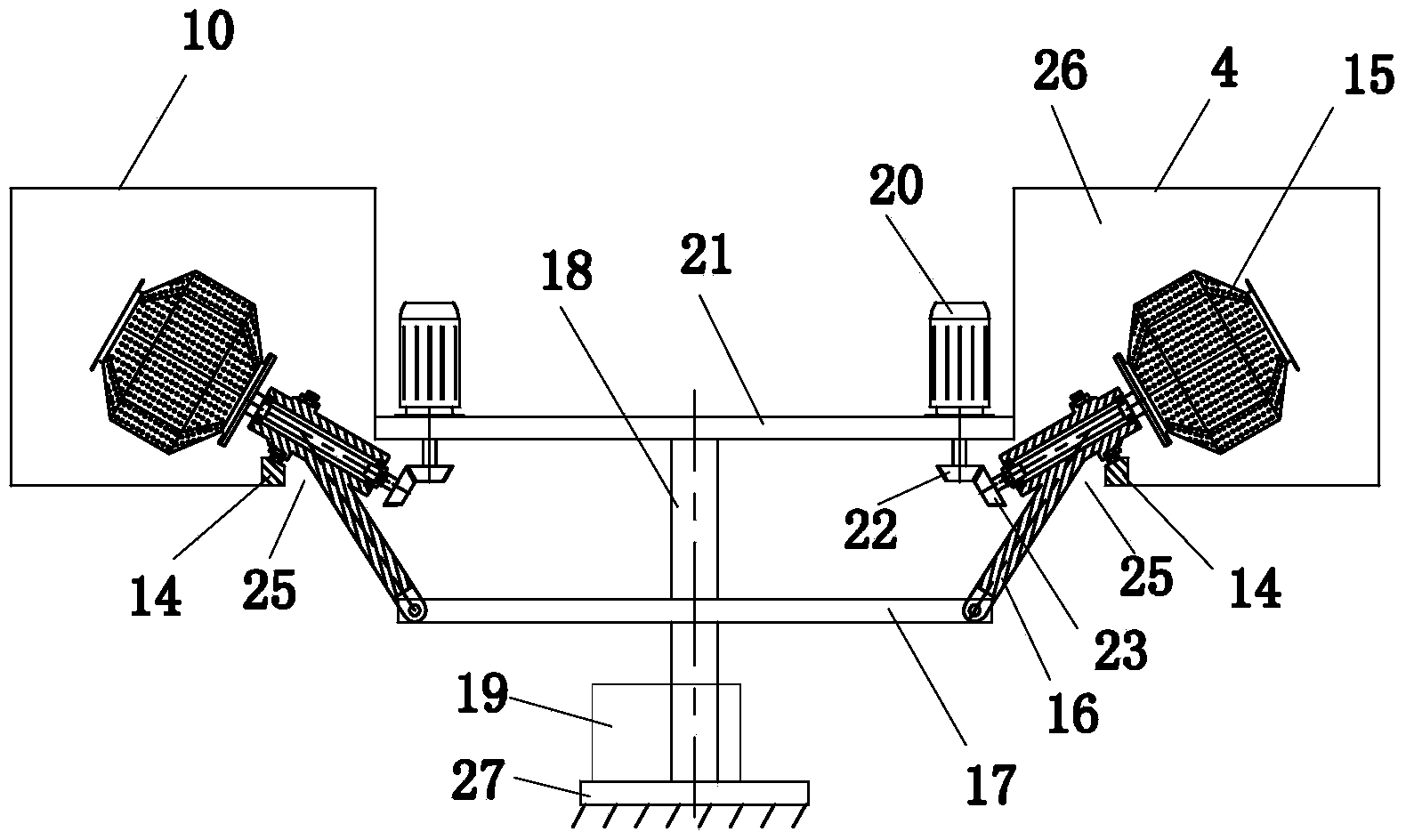

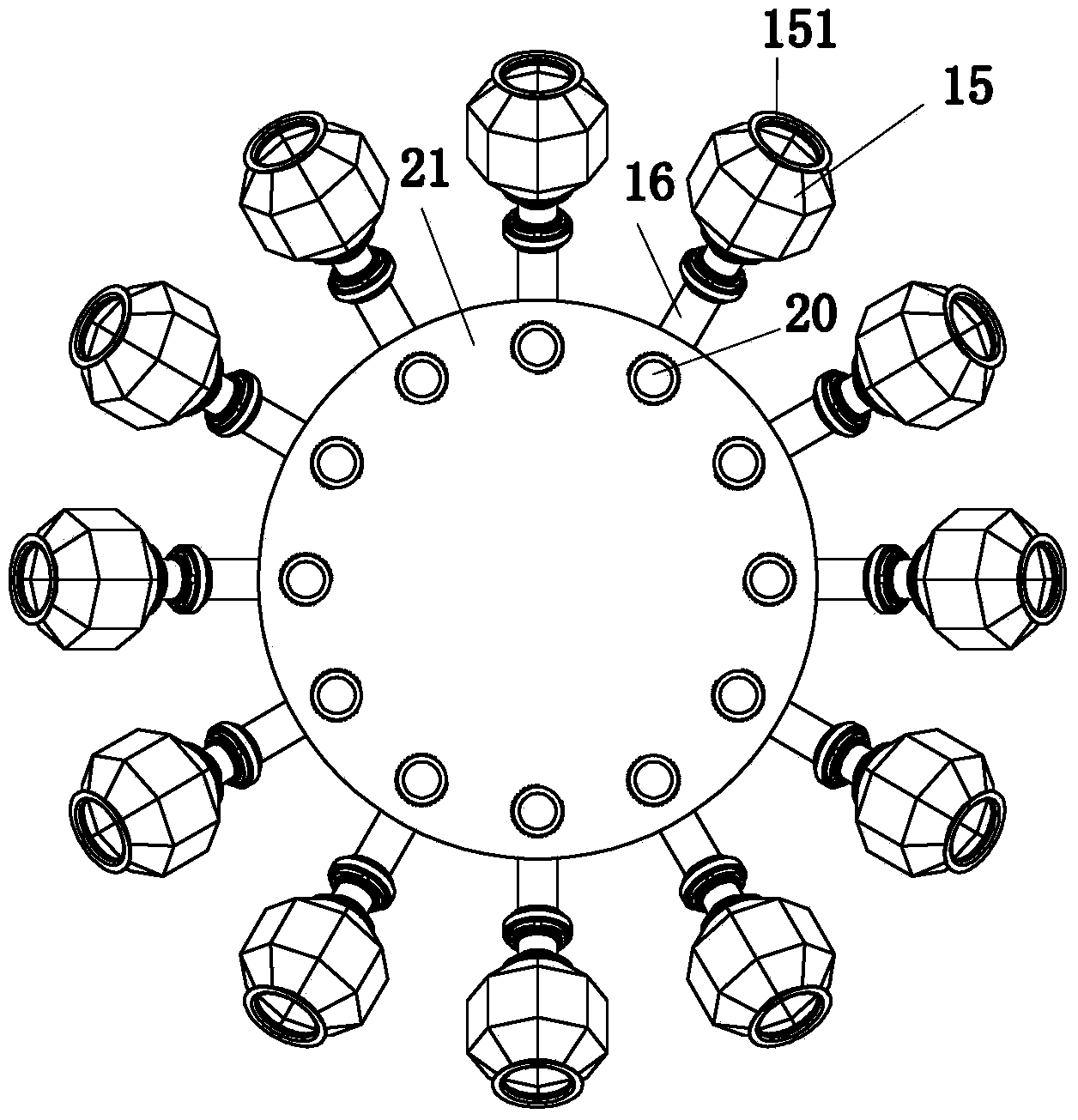

[0029] see Figure 1 to Figure 4 , an automatic painting equipment for zipper pulls, including a station room, a fitting 15, a support frame 16, a traveling device, an autorotation device, a feeding device, an unloading device and a control system, and the control system controls the traveling device, the autorotation device, and the station For the action of moving parts such as chamber partitions, feeding devices, and unloading devices, the fixture 15 is supported in the support bracket 16, and travels between each chamber through the walking device. The fixture can rotate during the process through the rotation device. Among them, the working chamber made of steel plates is connected end to end to form a closed ring, which can be a perfect circle or a ring with a long hole. The rotation device and the traveling device are located in the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com