Automatic sorter of kitchen waste

A technology for automatic sorting of kitchen waste, applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. It does not have practical problems, and achieves the effect of improving the sorting effect, the separation is complete, and the structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

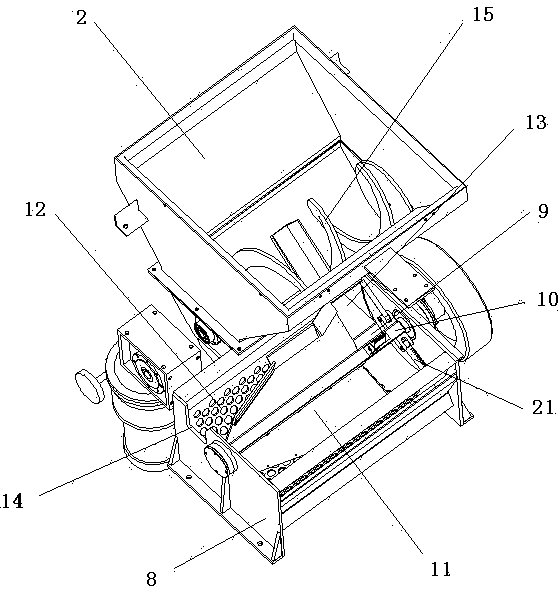

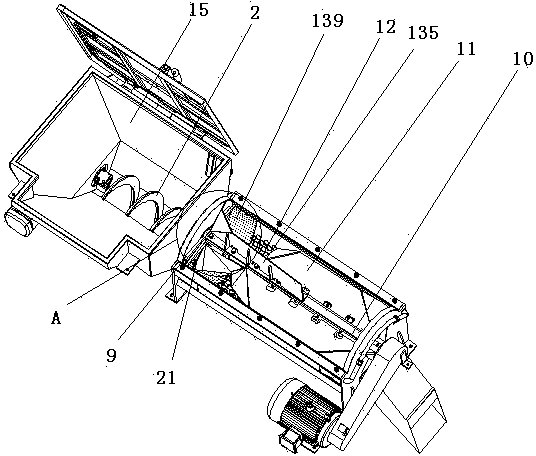

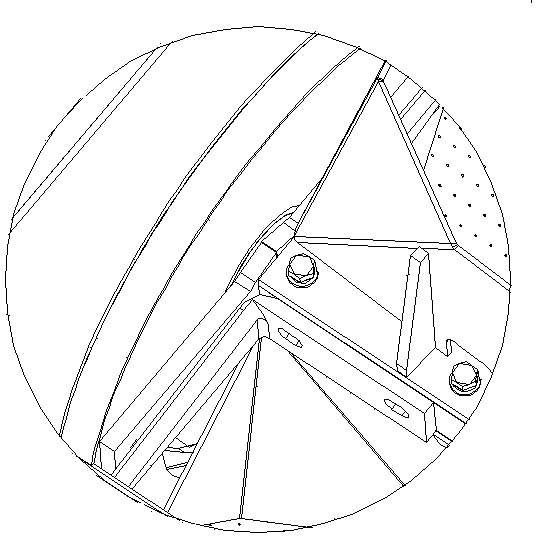

[0032] Embodiment 1: An automatic sorting device for kitchen waste, which includes a screening tank, a screening cover plate, a separation shaft, a separation blade, a filter screen and a separation motor, and the upper end of the screening tank 8 is connected to the screening cover plate , so that a separation cavity is formed in the screening tank 8 and the screening cover plate, a filter screen 12 and a separation shaft 10 are arranged in the screening tank 8, and a kitchen waste separation space is formed between the filter screen 12 and the screening tank 8, One end of the screening tank 8 is provided with a kitchen waste feed port 13, the other end is provided with a separated substance outlet 14, and the kitchen waste outlet and a liquid outlet are arranged below, and the kitchen waste feed port of the screening tank 8 The inner wall is provided with a crushing plate, and the screening tank 8 is connected to the upper hopper 2 through the kitchen waste feeding port 13. O...

Embodiment 2

[0033]Embodiment 2: An automatic sorting device for kitchen waste, which includes a screening tank, a screening cover plate, a separation shaft, a separation blade, a filter screen and a separation motor, and the upper end of the screening tank 8 is connected to the screening cover plate , so that a separation cavity is formed in the screening tank 8 and the screening cover plate, a filter screen 12 and a separation shaft 10 are arranged in the screening tank 8, and a kitchen waste separation space is formed between the filter screen 12 and the screening tank 8, One end of the screening tank 8 is provided with a kitchen waste feed port 13, the other end is provided with a separated substance outlet 14, and the kitchen waste outlet and a liquid outlet are arranged below, and the kitchen waste feed port of the screening tank 8 The inner wall is provided with a crushing plate, and the screening tank 8 is connected to the upper hopper 2 through the kitchen waste feeding port 13. On...

Embodiment 3

[0035] Embodiment 3. An automatic sorting device for kitchen waste, which includes a screening tank 8, a screening cover plate, a separation shaft, a separation blade, a filter screen and a separation motor, and the upper end of the screening tank 8 is connected to the screening cover plate. connected, so that a separation cavity is formed in the screening tank 8 and the screening cover plate, a filter screen 12 and a separation shaft 10 are arranged in the screening tank 8, and a kitchen waste separation space is formed between the filter screen 12 and the screening tank 8 One end of the screening tank 8 is provided with a kitchen waste feed port 13, the other end is provided with a separated substance outlet 14, and the kitchen waste outlet and a liquid outlet are provided below, and the kitchen waste feed of the screening tank 8 The inner wall of the mouth end is provided with a crushing plate, the screening tank 8 is connected to the upper hopper 2 through the kitchen waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com