Oriented structural straw board and preparation method thereof

A technology of wheat straw board and wheat straw, which is applied in the field of oriented structure wheat straw board and its preparation, can solve the problems of increasing carbon dioxide emission and non-utilization, and achieve the effects of reducing emission, reducing incineration, and excellent and stable structural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

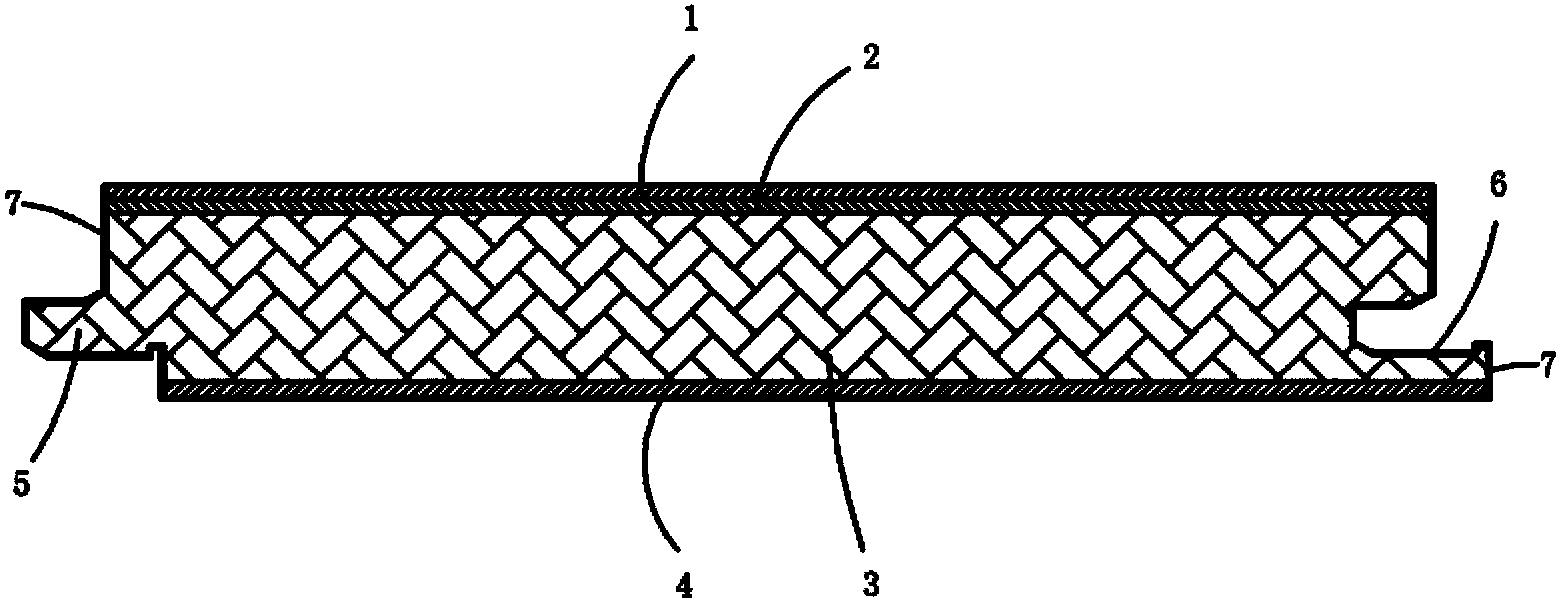

[0036] Examples, see attached figure 1 , a wheat straw board with an oriented structure, comprising a board body, the thickness of the board body is 12mm, and it has a layered structure, which consists of wood grain paper layer 1, wear-resistant paper layer a2, base layer 3 and wear-resistant paper from top to bottom Layer b4; the material of the base layer is wheat straw, and a multi-layer structural board formed by using wheat straw as a raw material and using modified isocyanate resin as an adhesive after directional paving and hot pressing; one end of the board body is set There is a locking male slot 5, and the other side is provided with a locking female slot 6.

[0037] The four sides of the board body are edge-sealed with white transparent granular wax 7, which is moisture-proof and not afraid of water.

[0038] The process flow of the present invention is: base material health preservation—hot pressing—cooling plate—stacking—semi-finished product health preservation—...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com