Vehicle movement direction control mechanism

A movement direction and control mechanism technology, applied in control devices, mechanical equipment, transmission devices, etc., can solve the problems of easy mechanical failure, large transmission torque loss, poor customer satisfaction, etc., and achieve reliable parking brake function. , Improve safety performance and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

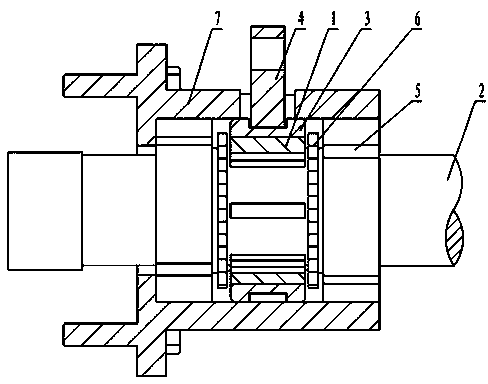

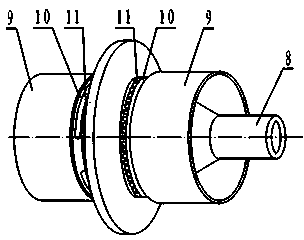

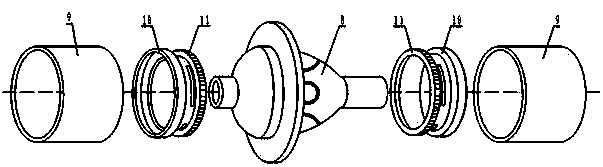

[0023] see figure 2 , image 3 , Figure 4 , Figure 5 , the present invention includes a differential case 8, a transmission case 9, a solenoid valve 10 and a one-way clutch 11, and the transmission case 9, the solenoid valve 10 and the one-way clutch 11 all include symmetrically arranged differential case 8 The two parts on the left and right sides, the valve seat 10-1 and the valve core 10-2 of the solenoid valve 10 are both sleeve structures, the valve seat 10-1 of the solenoid valve is fixedly assembled with the transmission housing 9 on the same side, and the solenoid valve The spool 10-2 is fixedly assembled with the one-way clutch 11 on the same side, and the transmission housing 9 is sleeved on the outside of the differential housing 8.

[0024] The present invention also includes a control unit, a wheel speed sensor and a gear position sensor, the input end of the control unit is connected with the wheel speed sensor and the gear position sensor, and the output e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com