A double-deck trolley capable of conducting oil collection and double-sided force delivery and hoisting

An oil-conducting oil-collecting, trolley technology, applied in trolleys, multi-axis trolleys, trolley accessories, etc., can solve the problems of increasing labor intensity, not meeting ergonomic design requirements, affecting handling quality, etc., and reducing bending The effect of working range, reducing oil pollution on the ground, and protecting the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention can be explained in more detail through the following examples, and the purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples.

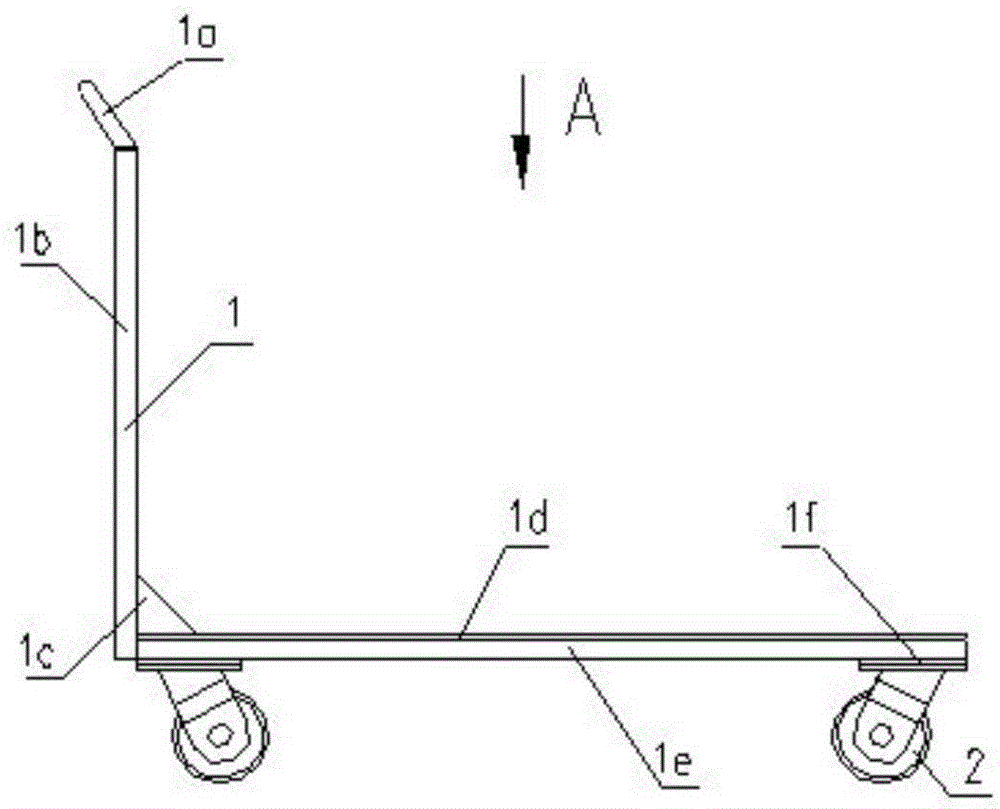

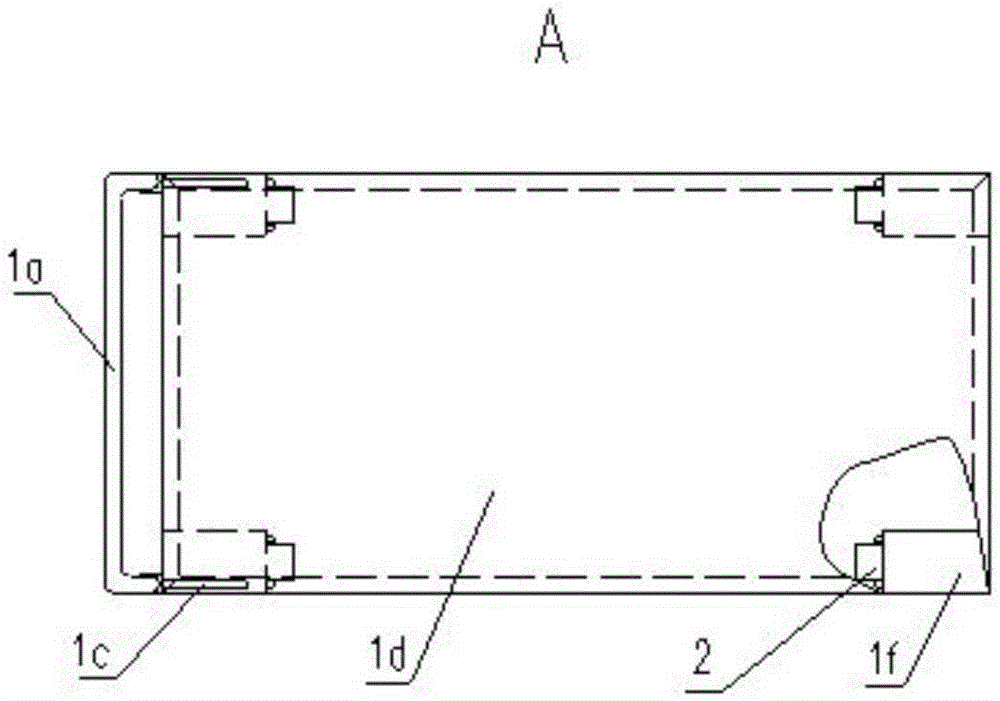

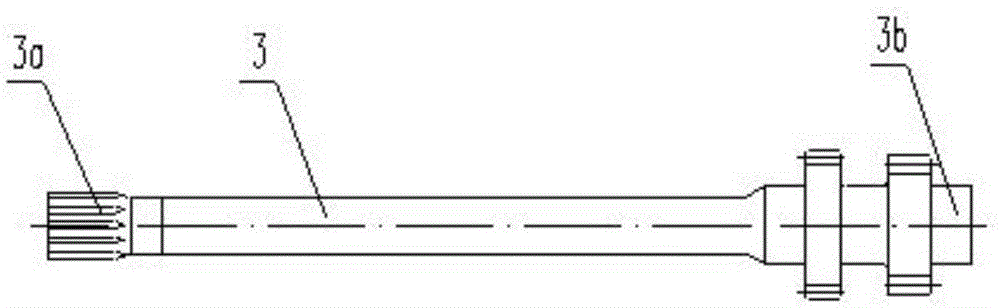

[0065] combined with Figure 11-23 The described double-deck trolley capable of conducting oil collection and double-sided force delivery and hoisting includes a double-deck frame assembly 6 and shock-absorbing casters 7, respectively at the four corners of the lower part of the double-deck frame assembly 6 Equipped with shock-absorbing casters 7, the double-deck trolley that can conduct oil collection and double-sided force delivery and lifting according to the present invention also includes a load-bearing and oil-guiding assembly 8 and an oil collection assembly 9. The frame assembly 6 is a two-layer car body structure. The upper layer is provided with an upper frame weldment 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com