Method for continuously producing pseudoboehmite by using ejector

A technology of pseudo-boehmite and ejector, applied in the field of continuous production of pseudo-boehmite by using ejector, which can solve the problems of high labor intensity, low productivity, and large fluctuations in product quality, and achieve low labor intensity and high production efficiency High and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

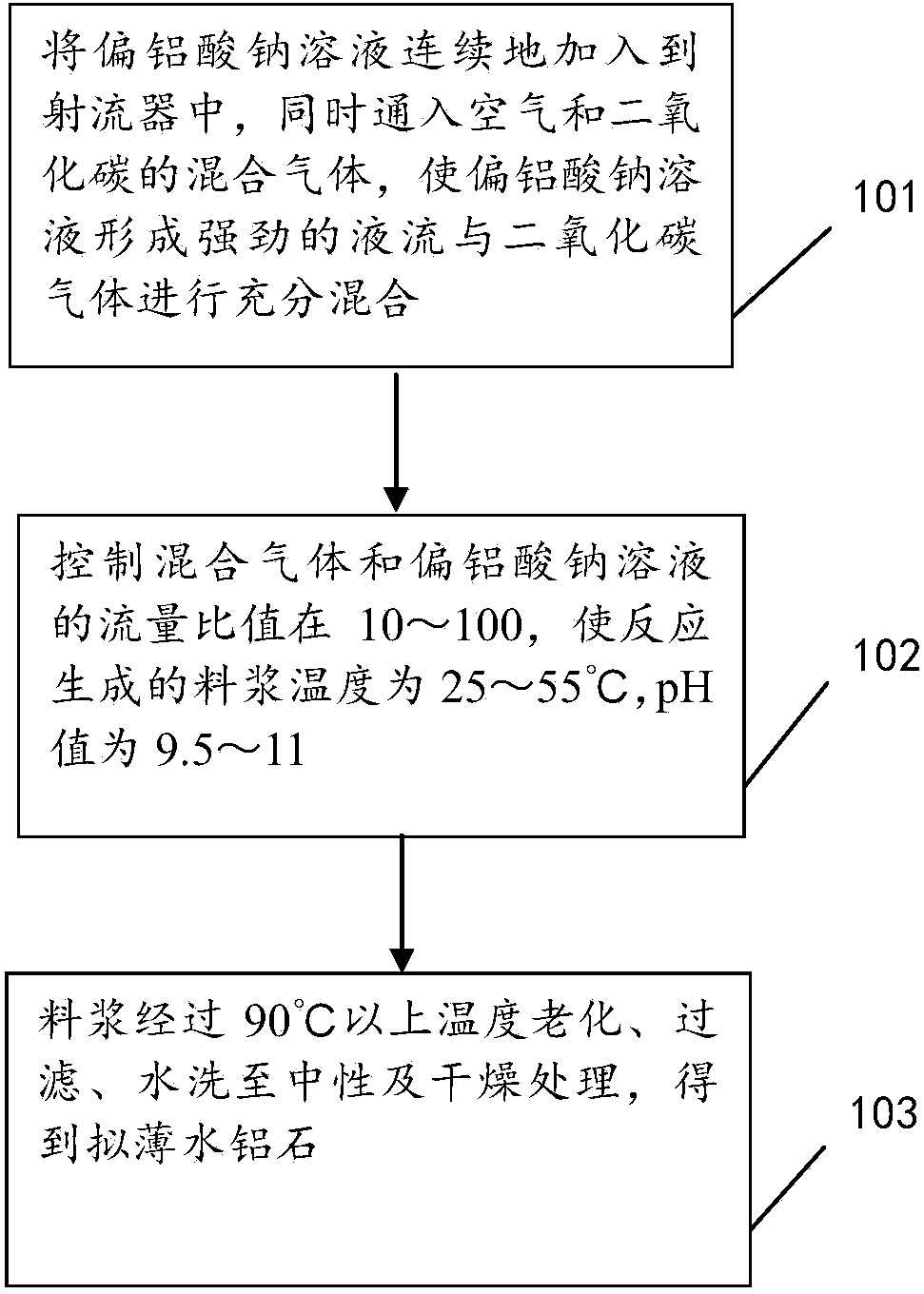

Method used

Image

Examples

Embodiment 1

[0033] The sodium metaaluminate solution with an alumina concentration of 15.9g / L is continuously added to the ejector through a pump, and a mixed gas of air and carbon dioxide is introduced into the ejector at the same time, and the volume percentage of carbon dioxide in the mixed gas is 30%. , the pressure of the mixed gas is 0.3MPa, so that the sodium metaaluminate solution forms a strong liquid flow and is fully mixed with carbon dioxide gas to produce many and fine bubbles; the flow ratio of the mixed gas and the sodium metaaluminate solution is controlled to be 10, so that When the temperature of the slurry generated by the reaction is 25°C and the pH value is 9.5, the gelation is stopped; the slurry obtained by the reaction is transported to the aging tank through the channel, and the temperature of the slurry is raised in the aging tank, and the aging temperature is 90°C; the aged The slurry was filtered, and the filter cake was washed with water to neutrality; the wash...

Embodiment 2

[0035] The sodium metaaluminate solution with an alumina concentration of 25.2g / L is continuously added to the ejector through a pump, and a mixed gas of air and carbon dioxide is introduced into the ejector at the same time, and the volume percentage of carbon dioxide in the mixed gas is 40%. , the pressure of the mixed gas is 0.2MPa, so that the sodium metaaluminate solution forms a strong liquid flow and fully mixes with the carbon dioxide gas to produce many and delicate bubbles; the flow ratio of the mixed gas and the sodium metaaluminate solution is controlled to be 30, so that When the temperature of the slurry generated by the reaction is 30°C and the pH value is 9.5, the gelation is stopped; the slurry obtained by the reaction is transported to the aging tank through the pipeline, and the temperature of the slurry is raised in the aging tank, and the aging temperature is 95°C; the aged The slurry was filtered, and the filter cake was washed with water to neutrality; th...

Embodiment 3

[0037] The sodium metaaluminate solution with an alumina concentration of 33.6g / L is continuously added to the ejector through a pump, and a mixed gas of air and carbon dioxide is introduced into the ejector at the same time, and the volume percentage of carbon dioxide in the mixed gas is 50% , the pressure of the mixed gas is 0.15MPa, so that the sodium metaaluminate solution forms a strong liquid flow and fully mixes with the carbon dioxide gas to produce many and delicate bubbles; the flow ratio of the mixed gas and the sodium metaaluminate solution is controlled to 40, so that When the temperature of the slurry generated by the reaction is 35°C and the pH value is 10, the gelation is stopped; the slurry obtained by the reaction is transported to the aging tank through the pipeline, and the temperature of the slurry is raised in the aging tank, and the aging temperature is 100°C; the aged The slurry was filtered, and the filter cake was washed with water to neutrality; the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap