System for comprehensive utilization of concentrated seawater by using solar pond

A technology for solar ponds and concentrated seawater, applied in solar heating systems, seawater treatment, solar thermal energy, etc., can solve the problems of large corrosion of seawater devices, impact on the environment, and high seawater salinity, so as to reduce operating costs, reduce impacts, and solve the problem of salt water. The effect of the use of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

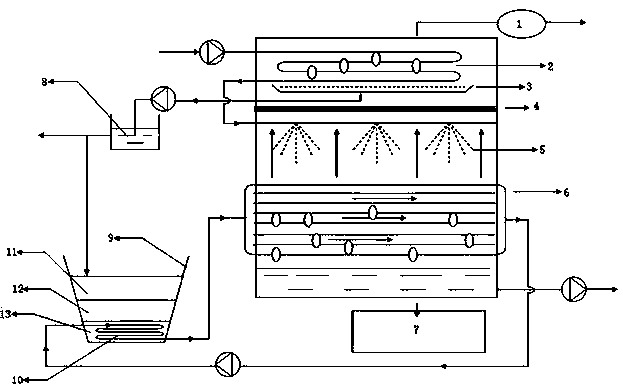

[0037] First, the pressure is reduced to 10Kpa by the vacuum pump 1, and then the concentrated seawater obtained by the existing seawater desalination system is pumped into the condenser 2. After heat exchange, the concentrated seawater enters the spray device 5, and the sprayed concentrated seawater is in the evaporator 6 The outer surface of the pipe evaporates from the top to the falling film, and the water vapor passes through the steam-water separator 4 and contacts the condenser 2 during the rising process, and condenses into fresh water. The condensed fresh water is collected by the fresh water collection device 3 and then enters the fresh water pool 8; The evaporated seawater becomes further concentrated concentrated seawater into the concentrated seawater pool, and is pumped to the salt pan for solar salt production.

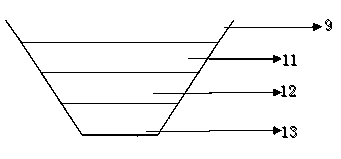

[0038] Construction of the solar pool: the pool structure of the solar pool part is in the shape of an inverted quadrangular truss, the bottom and the s...

Embodiment 2

[0042] First, the pressure is reduced to 17kPa by the vacuum pump 1, and then the concentrated seawater obtained by the existing seawater desalination system is pumped into the condenser 2. After heat exchange, the concentrated seawater enters the spray device 5, and the sprayed concentrated seawater is in the evaporator 6 The outer surface of the pipe evaporates from the top to the falling film, and the water vapor passes through the steam-water separator 4 and contacts the condenser 2 during the rising process, and condenses into fresh water. The condensed fresh water is collected by the fresh water collection device 3 and then enters the fresh water pool 8; The evaporated seawater becomes further concentrated concentrated seawater into the concentrated seawater pool, and is pumped to the salt pan for solar salt production.

[0043] Construction of the solar pool: the pool structure of the solar pool part is in the shape of an inverted quadrangular truss, the bottom and the s...

Embodiment 3

[0047] First, the pressure is reduced to 20kPa by the vacuum pump 1, and then the concentrated seawater obtained by the existing seawater desalination system is pumped into the condenser 2. After heat exchange, the concentrated seawater enters the spray device 5, and the sprayed concentrated seawater is in the evaporator 6 The outer surface of the pipe evaporates from the top to the falling film, and the water vapor passes through the steam-water separator 4 and contacts the condenser 2 during the rising process, and condenses into fresh water. The condensed fresh water is collected by the fresh water collection device 3 and then enters the fresh water pool 8; The evaporated seawater becomes further concentrated concentrated seawater, enters the concentrated seawater pool, and is pumped to the salt pan for solar salt production.

[0048] The construction of the solar pool: the pool structure of the solar pool part is in the shape of an inverted square prism, the bottom and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com