Method for lowering biuret content in high-tower granulated compound fertilizer and production facility thereof

A high-tower granulation and compound fertilizer technology, which is applied in the direction of fertilization equipment, fertilizer mixture, application, etc., to achieve the effects of reducing evaporated water, saving energy consumption, and reducing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

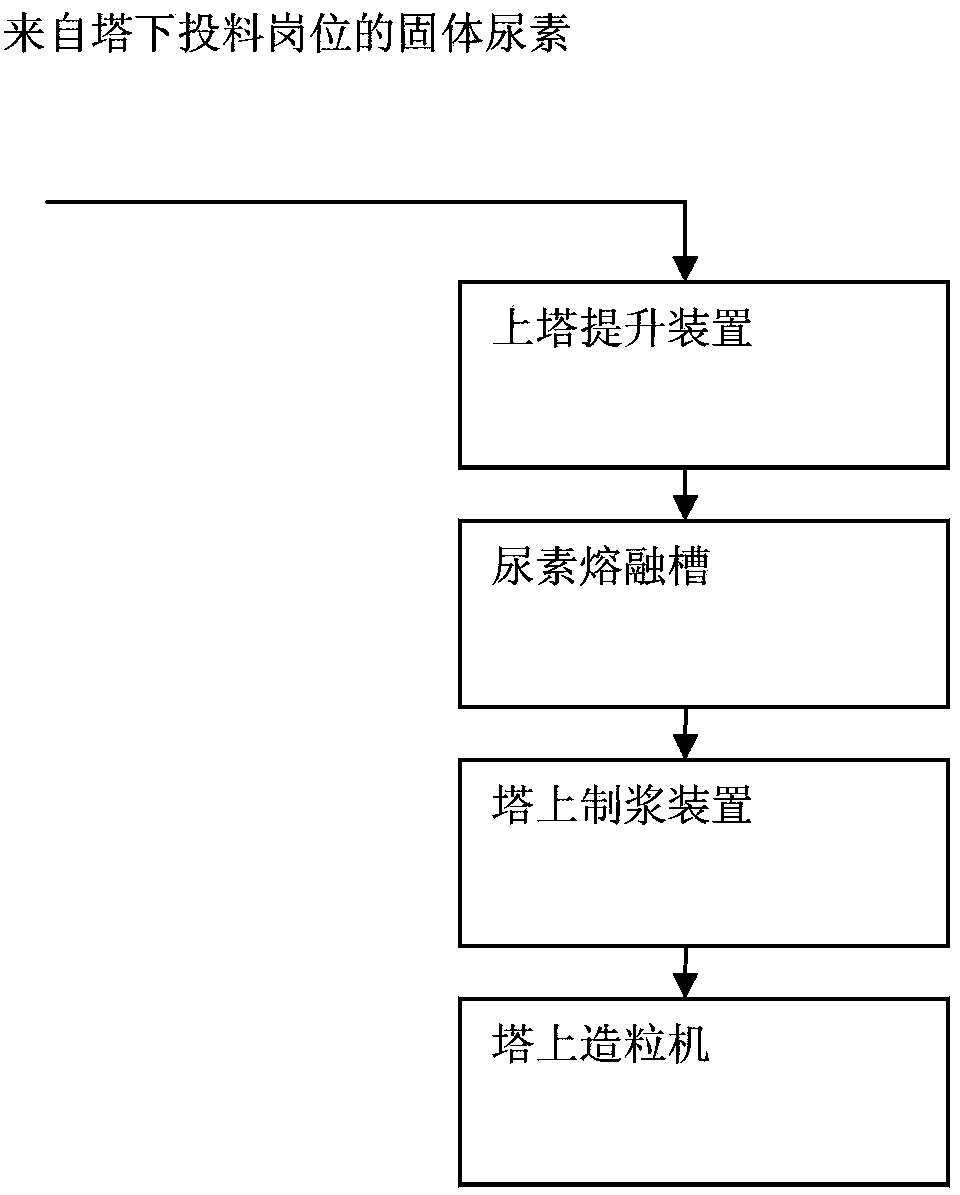

Image

Examples

Embodiment 1

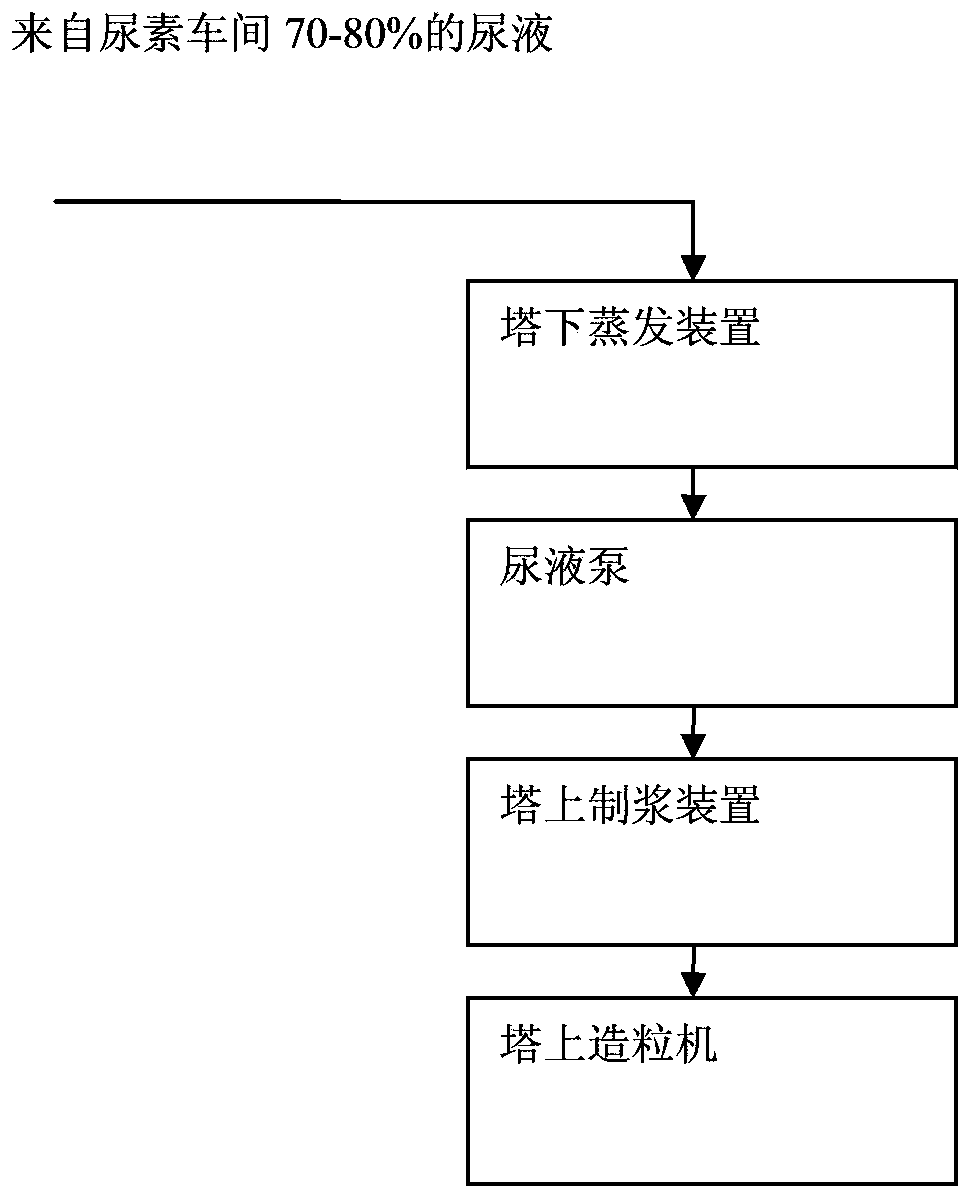

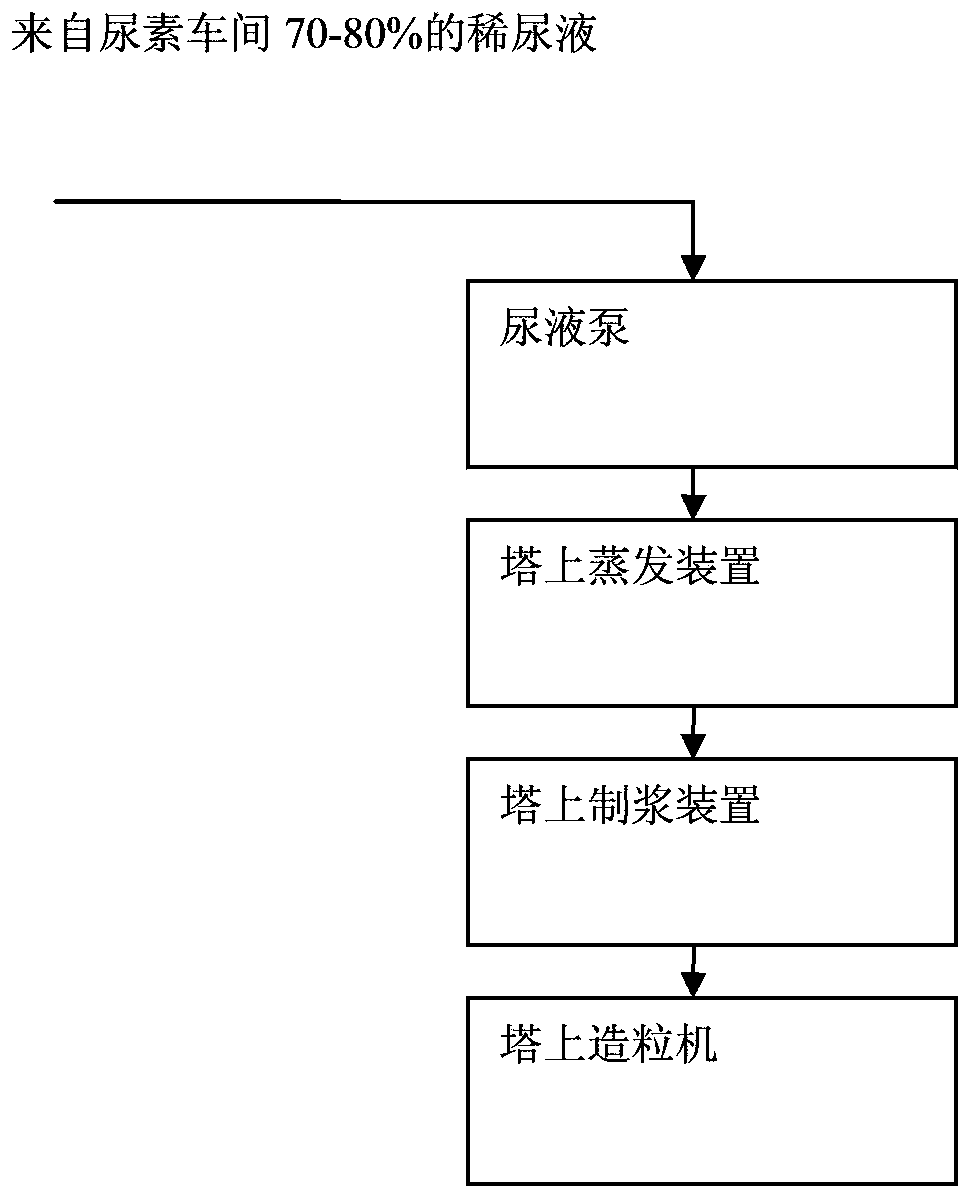

[0030] see image 3 , a method for reducing the content of biuret in high-tower granulated compound fertilizers. The dilute urine with a temperature of 80-90°C and a concentration of 70-80wt% from the urea workshop is pumped to the urea on the granulation tower with the pump body 8 Evaporation device, through evaporation and concentration, reaches the concentration of urine moisture required (95-99.75wt%) for urine-based compound fertilizer; the concentrated urine that reaches the standard enters the first-level mixing tank and the second-level mixing tank of the pulping device on the tower, Pre-mix with potassium fertilizer, phosphate fertilizer and auxiliary materials; after mixing, flow into the emulsifier of the pulping device on the tower to emulsify to obtain slurry; pass the slurry to the granulator on the tower for granulation to obtain urea-based compound fertilizer granules.

[0031] Firstly, use dilute urine with a temperature of 80-90°C and a concentration of 70-80...

Embodiment 2

[0034] see Figure 4 , a production equipment for reducing the biuret content of high-tower granulation compound fertilizer, including the tower body of the granulation tower, and the delivery device for conveying urine. In this example, the pump body 9 is used. Evaporation unit 1, pulping unit and granulator 5 for evaporative concentration. The pulping device includes a primary mixing tank 2 , a secondary mixing tank 3 and an emulsifier 4 . The evaporating device 1, the pulping device and the granulator 5 are all arranged on the tower, and are sequentially connected through conduits. The pump body 8 is connected with the pipeline of the tower to provide power to transport the urine to the evaporation device 1 on the tower through the pipeline.

Embodiment 3

[0036] The difference between this embodiment and Embodiment 2 is that the evaporation device 1 is arranged above the pulping device on the tower.

[0037] In addition, after the granulator 5, a screening device 6, a cooling device 7 and a packaging device 8 are sequentially connected, which are respectively used for subsequent screening, cooling and packaging processes.

[0038]In this way, the pump body 9 directly pumps the dilute urine from the urea plant to the evaporation device 1 on the tower for evaporation and concentration, and then transports it to the primary mixing tank 2 and the secondary mixing tank 3 for mixing, and then enters the emulsifier 4 and the production process. The granulator 5 performs emulsification and granulation. This process eliminates the severe condensation reaction due to the long residence time and high temperature during the transportation process when the concentrated urine is directly used, thereby reducing the generation of biuret during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com