Moving bed method for producing m-cresol and p-cresol through isomerization of o-cresol

A technology of o-cresol and moving bed, which is applied in the field of moving bed for the isomerization of o-cresol to produce m-cresol and p-cresol, which can solve the problems of short catalyst life and achieve the effect of overcoming the short life of catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0051] According to the method disclosed in US Patent No. 4,691,063, H-type ZSM-5 molecular sieves were prepared. H type ZSM-5 molecular sieve (SiO 2 / Al 2 o 3 Molar ratio=38) 10.0kg+10wt%Al 2 o 3 (Pseudo-boehmite powder) + 25wt% kaolin + 3000ml 10wt% nitric acid aqueous solution and 2000ml deionized water, mixed to prepare spherical particles. Then the spherical particles were dried in air at 60°C for 4 hours, at 120°C for 4 hours, and then calcined at 550°C for 3 hours.

[0052] With the product 10kg obtained above, 2wt% (NH 4 ) 2 HPO 4 The aqueous solution was soaked at room temperature for 12 hours, dried at 60°C for 4 hours in air, dried at 120°C for 4 hours, and then calcined at 520°C for 3 hours. 5kg of the product thus obtained was added to 3wt% SiCl 4 In the cyclohexane solution, stirred in an oil bath at 90°C for 4-6h, filtered, washed, then dried in air at 120°C for 8 hours, and calcined at 520°C for 4 hours to obtain a catalyst 1 with a Si loading of 2.0wt...

preparation Embodiment 2~5

[0054] Catalysts 2 to 5 were prepared in the same manner as in Preparation Example 1, except that mordenite, ZSM-11, Y zeolite, and MCM-22 were used instead of ZSM-5 in Preparation Example 1, respectively.

Embodiment 1

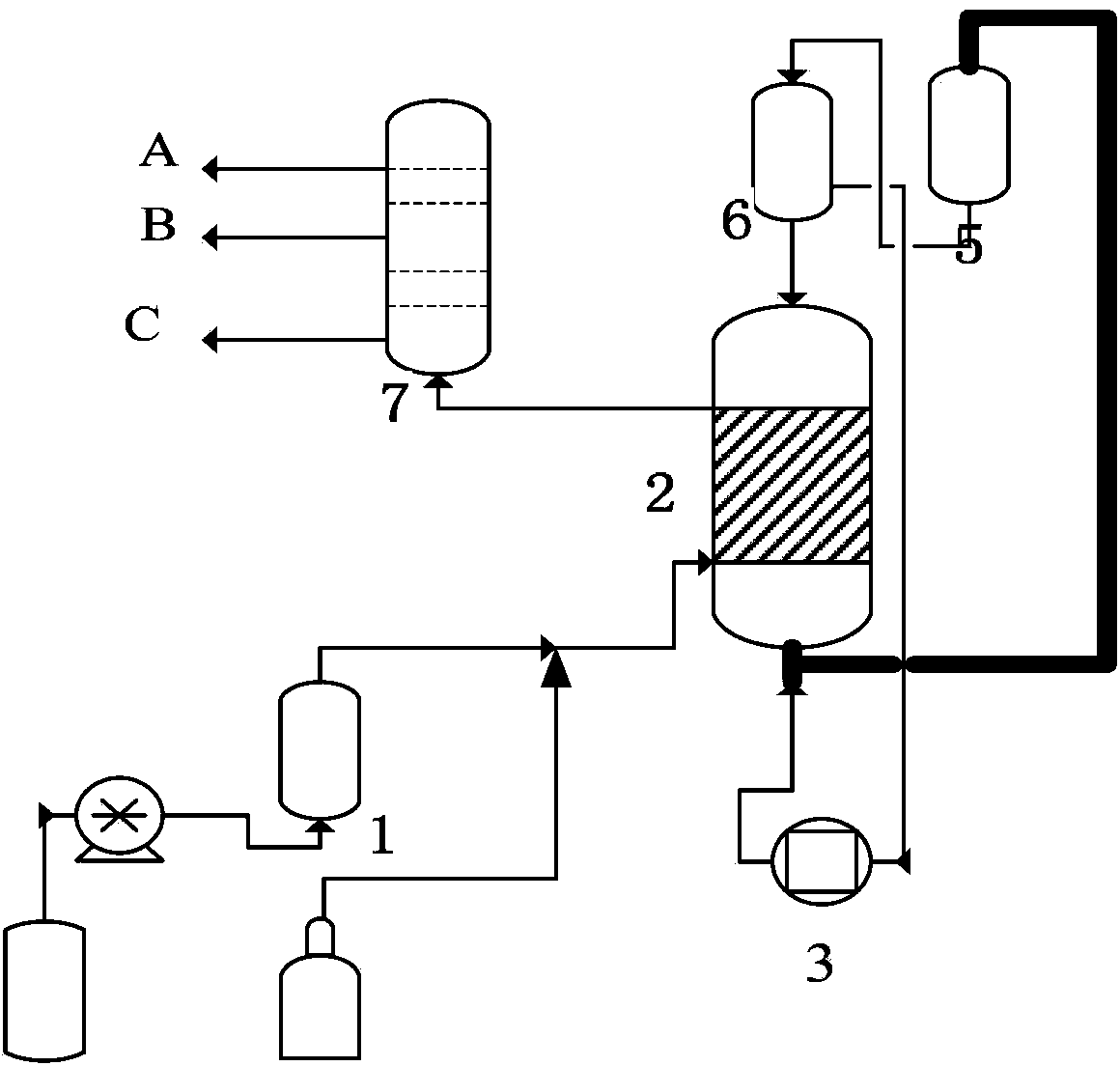

[0056] The o-cresol is gasified and superheated in the preheater 1 and mixed with the carrier gas to obtain the reaction raw material I; the reaction raw material I is passed into the moving bed reactor (purchased from Beijing Aerospace Century Star Technology Co., Ltd., model: non-standard Custom-made device, the reactor of 2500ml) is contacted with catalyst 1, obtains the reaction mixture II that is rich in m-cresol and p-cresol after isomerization reaction. The reaction conditions are: the loading amount of catalyst 1 is 2500ml, the reaction temperature is 380°C, and the volume space velocity of o-cresol is 1.0h -1 , nitrogen as the carrier gas. Reaction obtains the reaction mixture II containing m-cresol and p-cresol, enters rectifying tower 7 after cooling, obtains A cut through rectifying separation: phenol and o-cresol; B cut: m-cresol and p-cresol; and Fraction C: heavy fraction.

[0057] Then, the B fraction is passed into the product storage tank, and then separate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com