Material saving device and method for supporting transverse stress pile

A horizontal force-bearing and material-saving technology, applied in excavation, sheet pile walls, construction, etc., can solve the problems of increased construction risk and construction cost, large construction work surface size, large excavation and backfill engineering volume, etc., to achieve reinforcement Good effect, saving construction time and reducing spoil pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

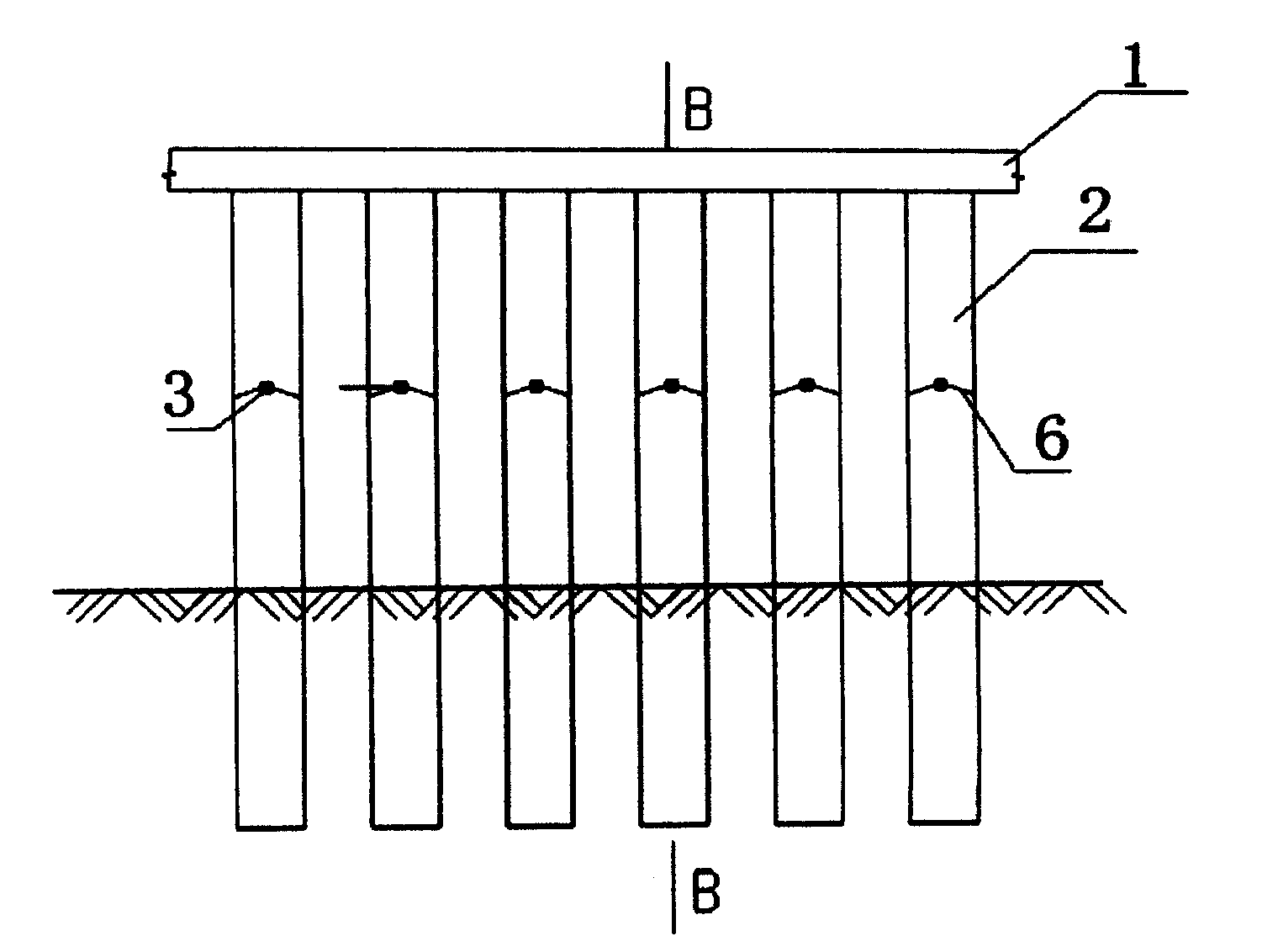

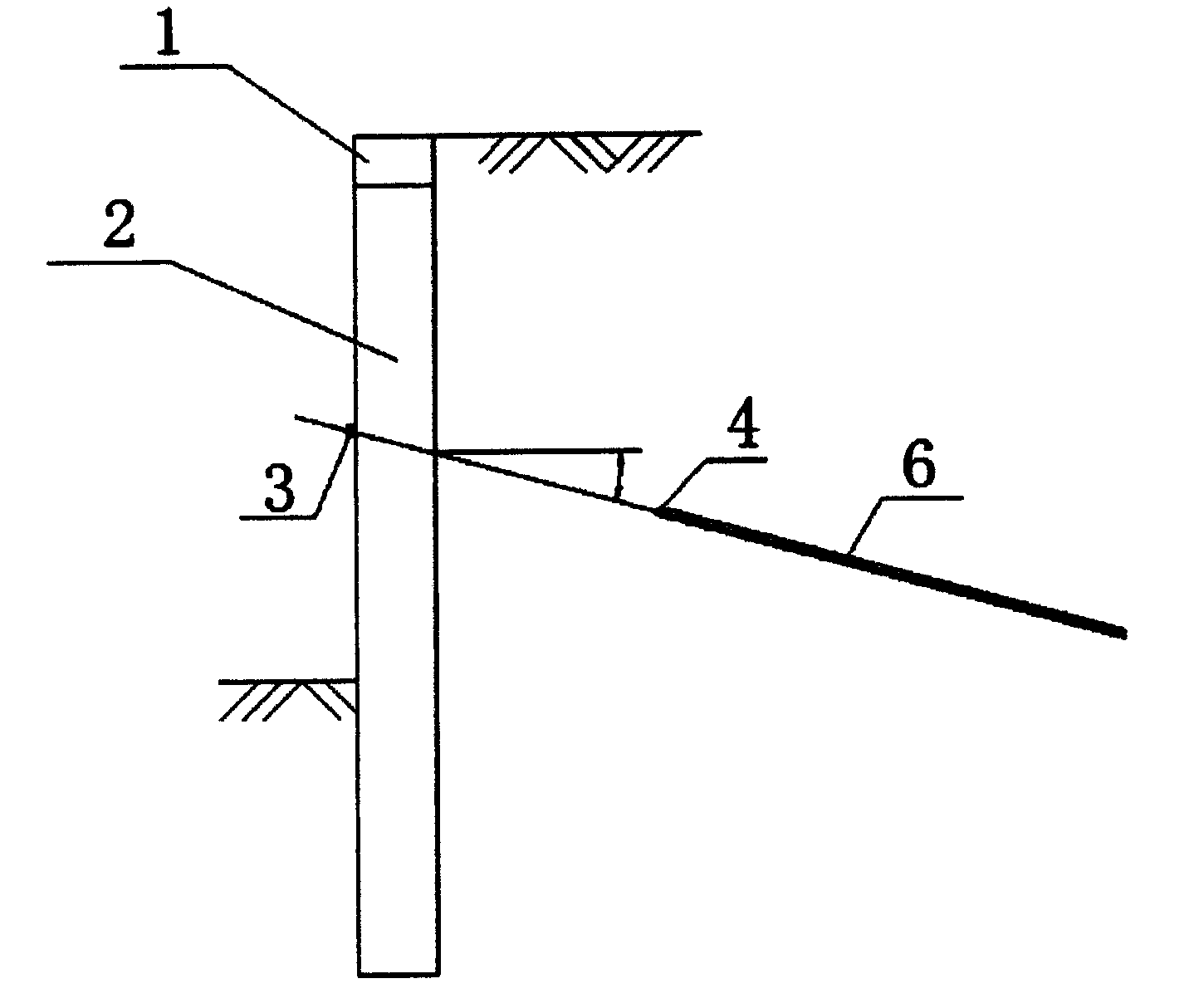

[0032] plan 1:

[0033] A material-saving device for supporting transversely stressed piles, comprising more than one pile body 2, and the pile bodies 2 are arranged side by side. The two-way support is connected to the steel strand system, and the steel strand system includes a plurality of sub-steel strands 6 fixedly connected to the two-way support 3 .

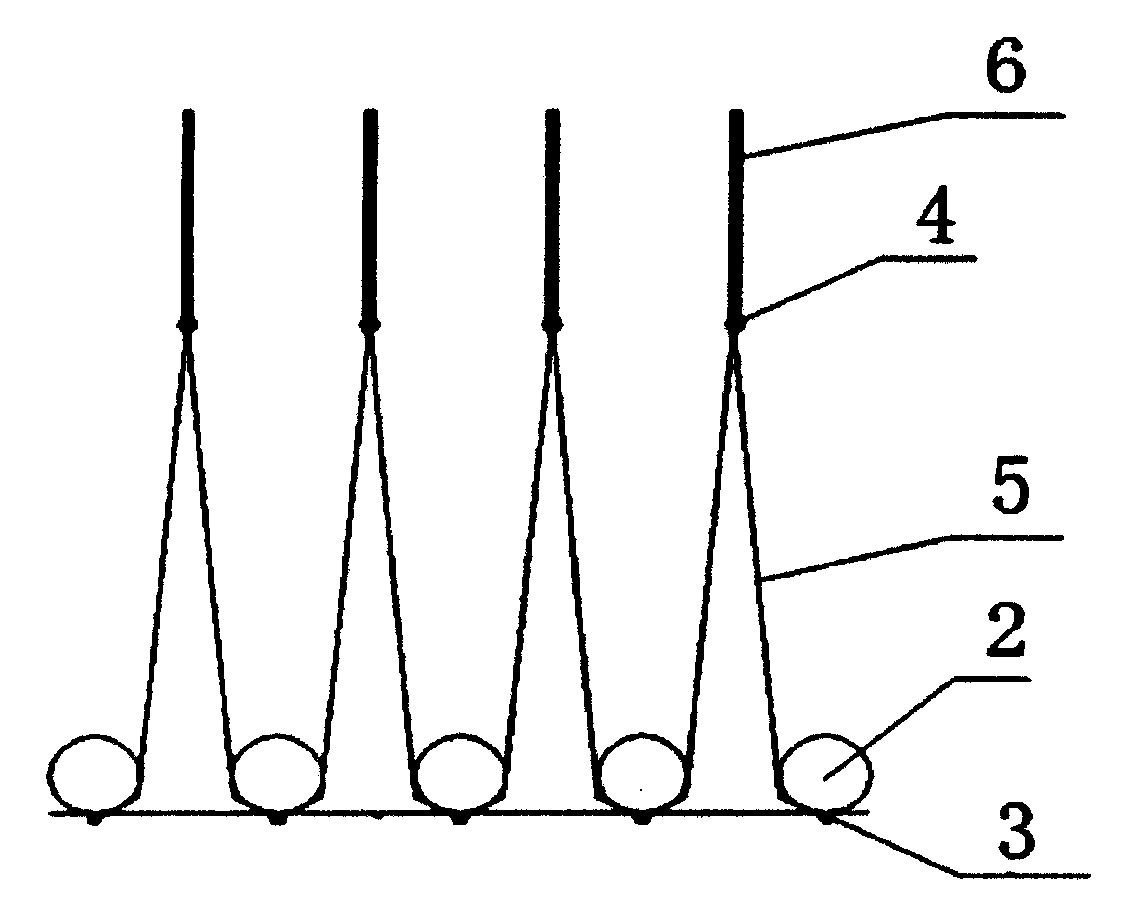

[0034] This patent mainly introduces double strands, but structures such as four strands are also applicable to this patent.

[0035] The more than one sub-steel strand 6, when the sub-steel strand 6 is inserted into a hole and grouted, it becomes a single anchor cable, and the ungrouted part of the steel strand is split into two symmetrical strands through the limit ring Steel strands; when the sub-steel strands are split into two strands and inserted into two holes for grouting, they become two anchor cables. In this case, the limit ring can be cancelled. Therefore, there will be no splitting of the sub-steel strands, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com