Energy-concentrating gas-saving infrared generator for gas appliances

A technology for generators and gas appliances, which is applied in the direction of burners, combustion methods, and combustion types. Effect of heat loss and improvement of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

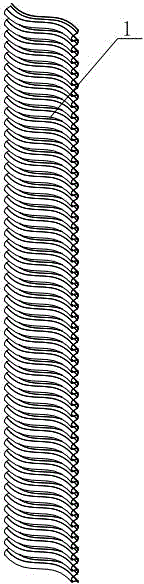

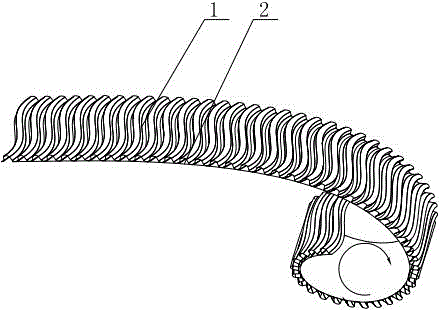

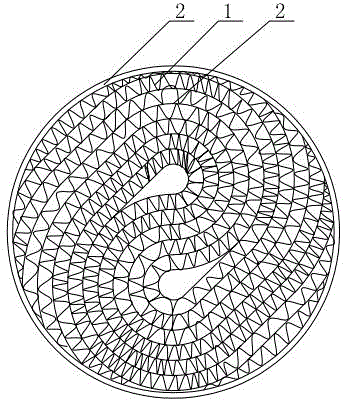

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, the energy-gathering and gas-saving infrared generating body for gas appliances in this embodiment includes a long metal strip, and the long metal strip is divided into a corrugated belt 1 and a flat belt 2. The corrugated belt 1 and the flat belt 2 overlap each other and are wound or stacked in parallel to form In the infrared generating body, a pipeline through which gas passes is formed between the convex embossing on the surface of the corrugated belt 1 and the plane of the flat belt 2 . The pipeline is a bent structure, which is a curved through hole.

[0034] Such as figure 1 As shown, the transverse section and the longitudinal section of the corrugated zone 1 both form a regular wavy structure.

[0035] Such as Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com