PV module pid level test method and test system for setting water film thickness

A technology of water film thickness and test method, which is applied in the monitoring of photovoltaic systems, electrical components, photovoltaic power generation, etc., can solve the problems of different test conditions, different severity, and low component performance, so as to improve test efficiency and test The effect of simple steps and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

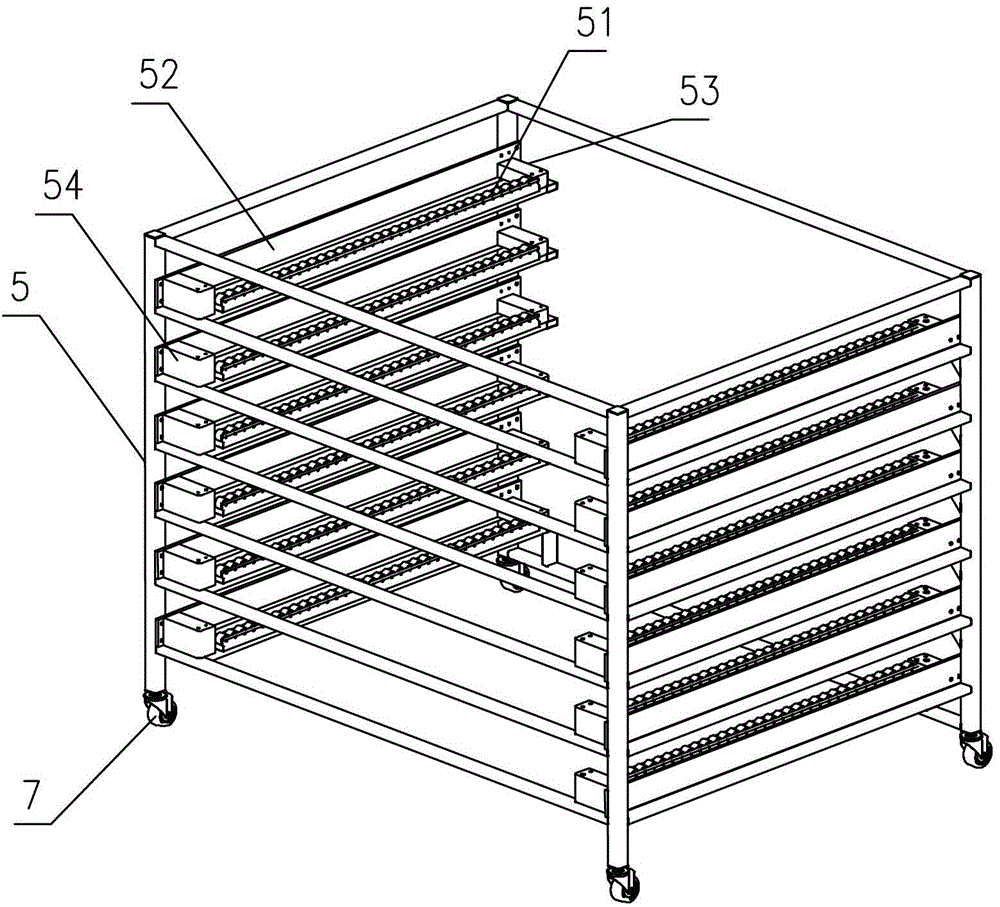

[0038] A kind of PV module PID level testing method of setting water film thickness of the present invention comprises the following steps:

[0039] (1) Test and record the initial data of the tested PV modules; the initial data generally include electrical performance parameters, EL defect parameters and wet leakage parameters, and the parameters are obtained by testing the electrical performance tester, EL defect tester and wet leakage tester respectively.

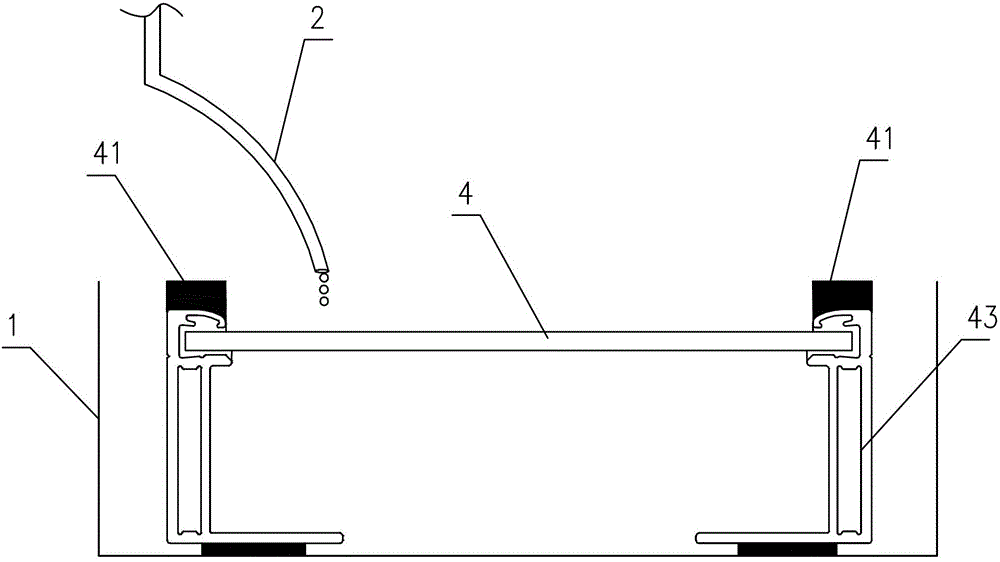

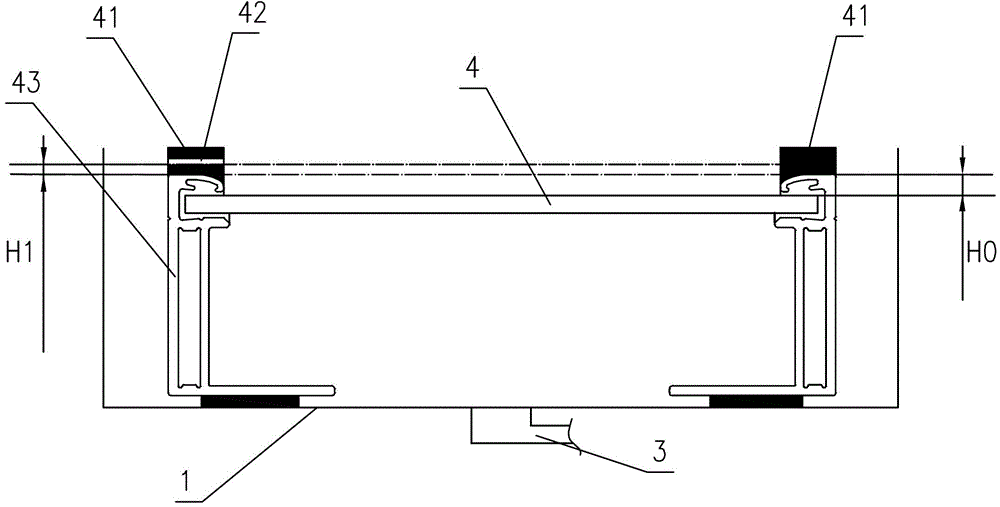

[0040] ⑵According to the set water film thickness, set a water retaining dam on the circumference of the light-receiving surface frame of the tested PV module. Glue heat-resistant tape to form a retaining dam, check the adhesion between the retaining dam and the frame to ensure that it will not leak due to poor adhesion, and the temperature resistance of the retaining dam is higher than the ambient temperature set by the environmental test chamber;

[0041] (3) Set up an overflow on the side wall of the retaining dam, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com