Manufacturing method for TSV and first layer re-wiring layer with no need of CMP

A technology of rewiring layer and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of high cost and many process steps, reduce process cost, reduce process steps, and eliminate CMP The effect of the polishing step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with drawings and embodiments.

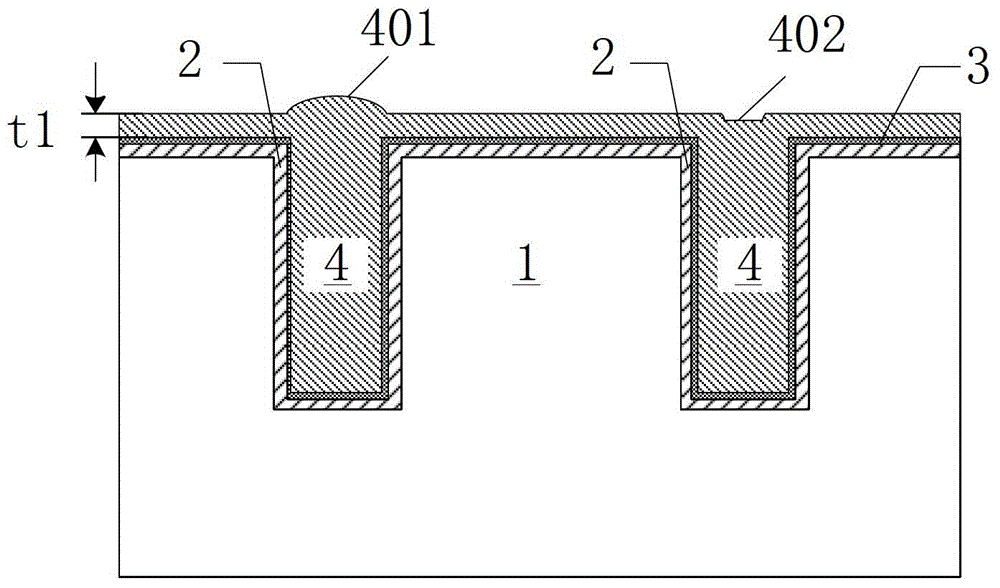

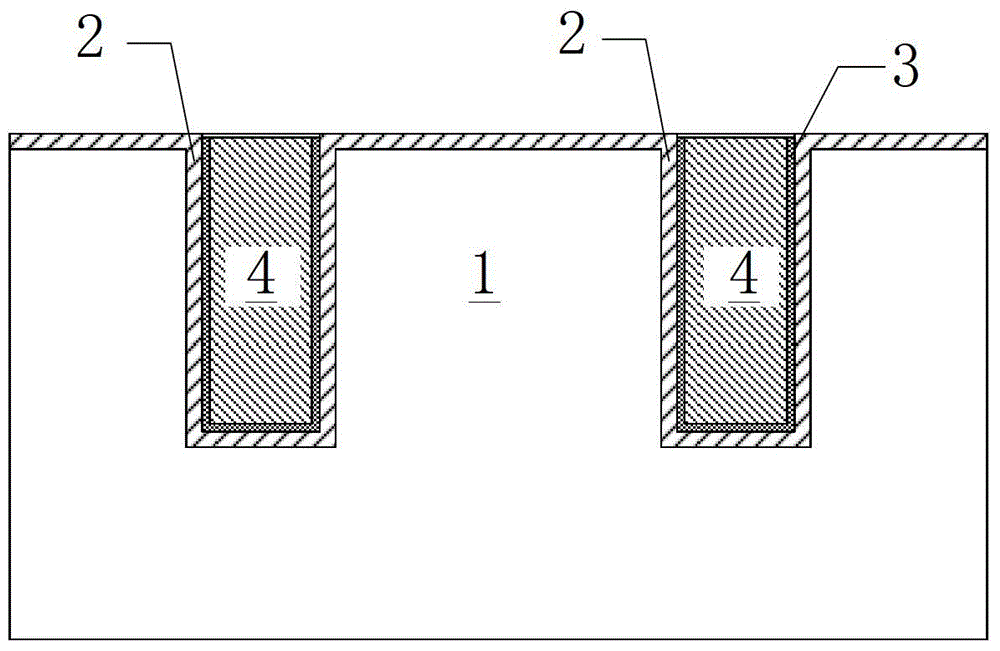

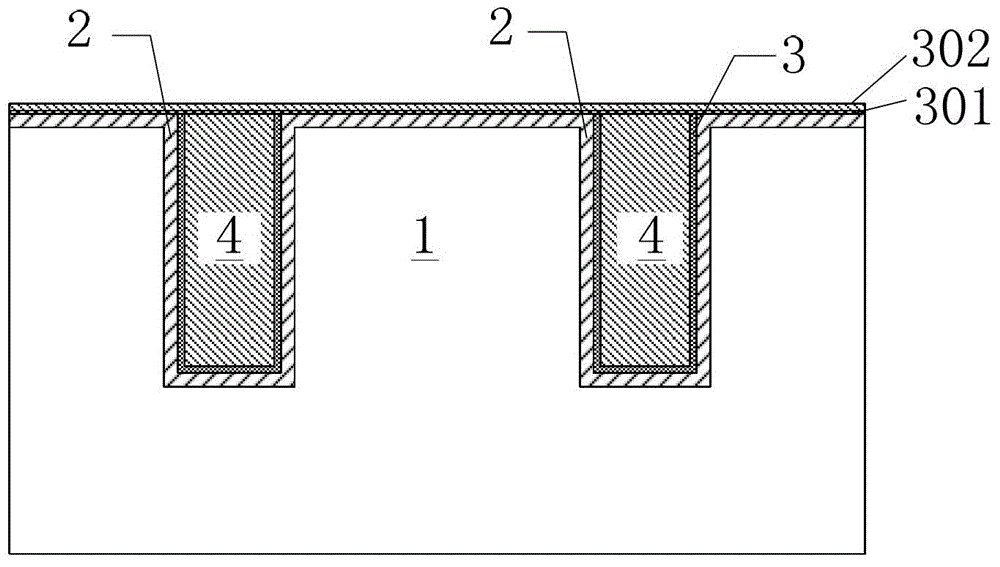

[0038] The reason why the traditional method does not reuse the diffusion barrier layer and the seed layer is that the CMP process cannot control the thickness of the remaining metal layer, and cannot guarantee that after CMP treatment, a thin layer of metal remains on the surface evenly as the seed layer for RDL electroplating. To ensure performance, the surface metal and diffusion barrier layer are generally removed, and then re-deposited. The present invention designs a special processing flow, and provides a manufacturing method of TSV and the first layer of rewiring layer without using CMP. Image 6 As shown, each process step is introduced below.

[0039] (1) S0: if Figure 7 As shown, the TSV electroplating filling and annealing operations have been completed on the substrate 1, the filling material is metal copper 4, and the filling method is electroplating. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com