Arrangement in wire feeding device of welding machine and method for moving welding wire

A technology of supplying device and welding machine, which is applied in welding equipment, transportation and packaging, arc welding equipment, etc., can solve the problems of difficulty in uniform supply of welding wire, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

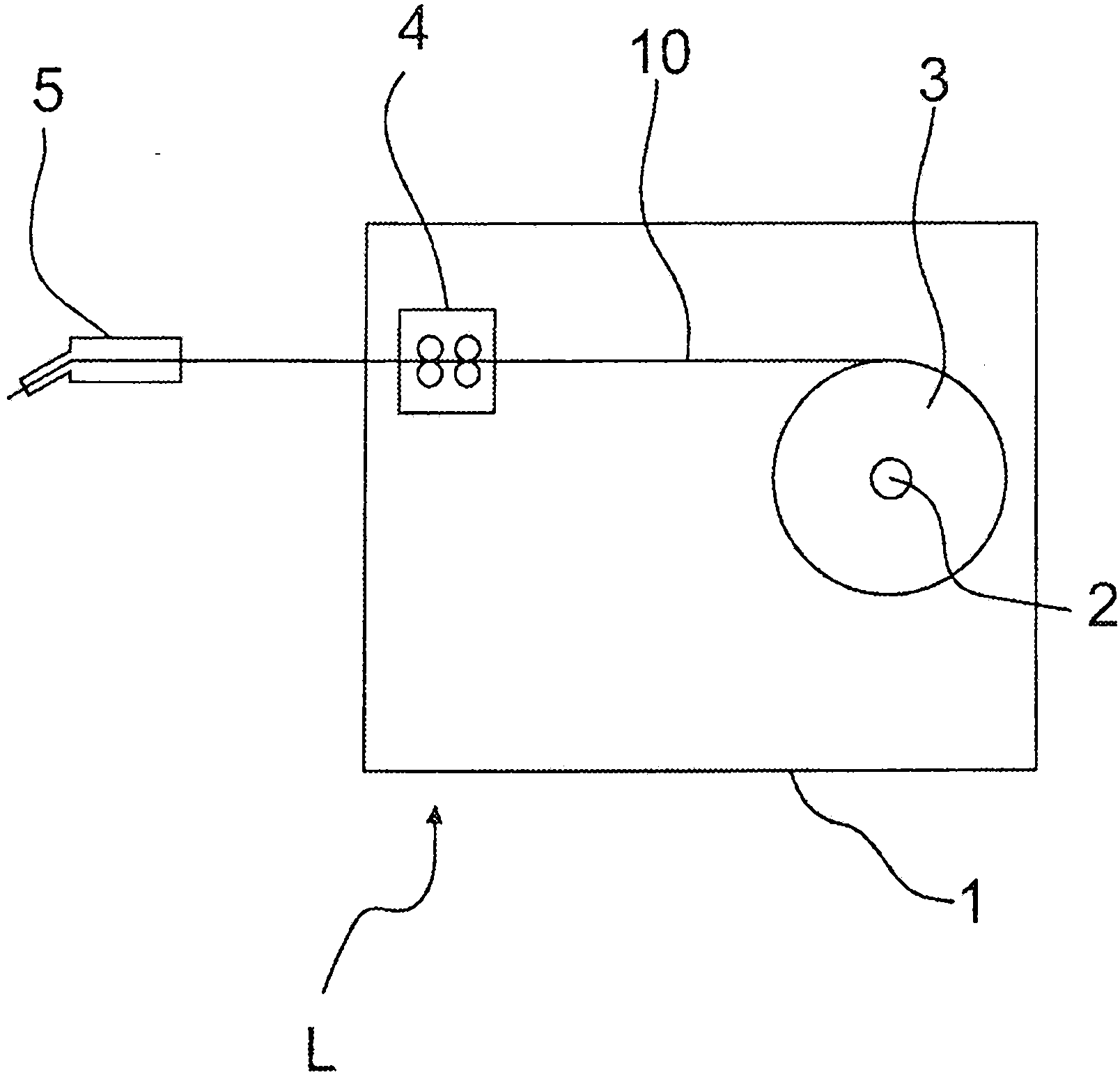

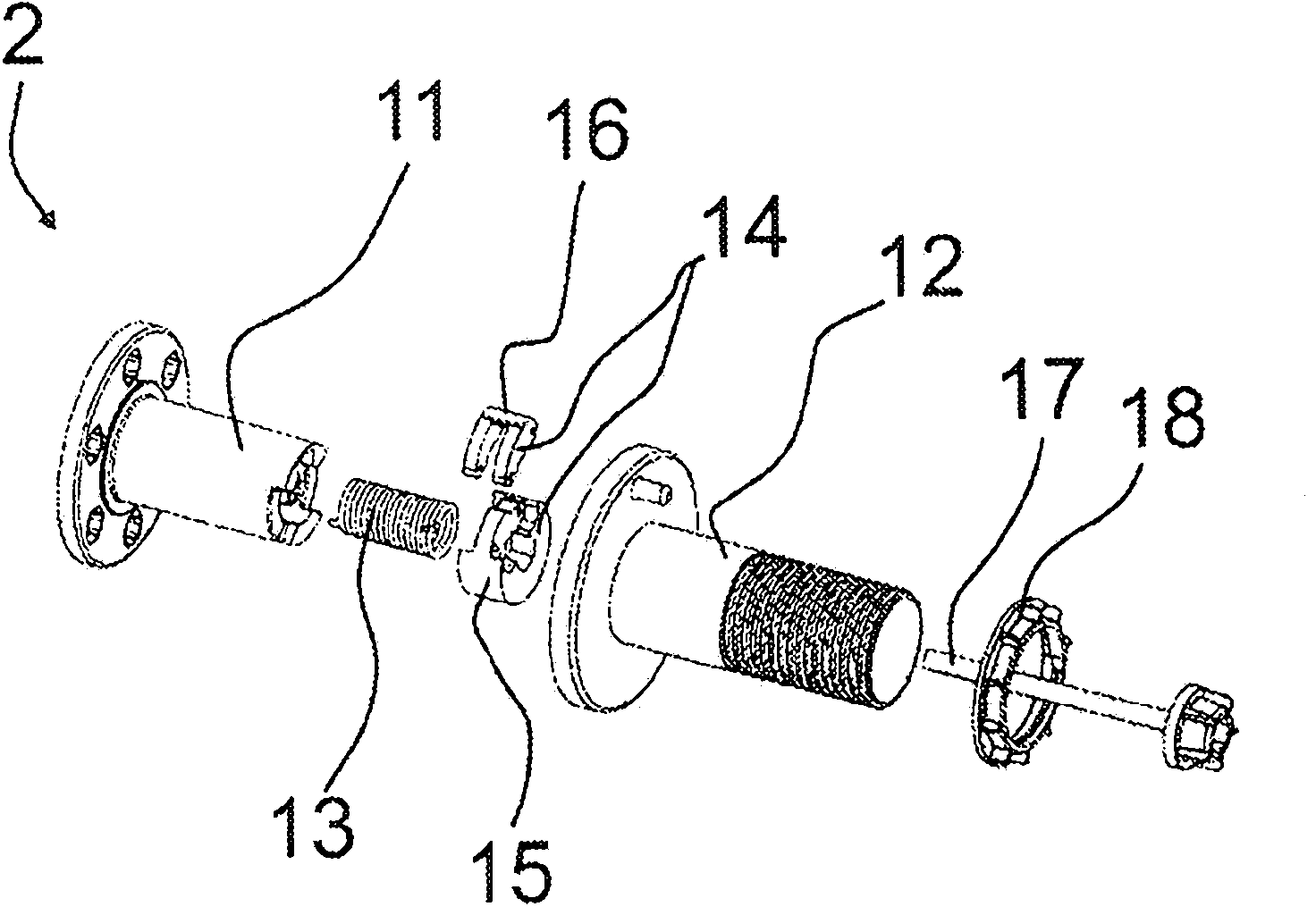

[0030] figure 1 A wire feeding device L is shown, which in this example is itself an overall device. The welding wire feeding device L can be positioned in relation to the power source, in relation to the welding torch or as a combined device, the welding wire feeding device L described in the claims is not limited to one of these alternatives, but it can be positioned in the claims vary within the required range. The welding wire supply device L comprises a frame 1 and a hub system 2 arranged in the frame, in association with which a welding wire reel 3 is arranged. The welding wire coil 3 comprises a welding wire 10 which is unwound from the welding wire coil 3 by means of a welding wire supply mechanism 4 and fed by the welding wire supply mechanism 4 to a welding torch 5 and via which a welding seam is formed. When the wire coil 3 is unwound, ie when fed towards the wire supply mechanism 4 , in other words when the wire supply mechanism 4 pulls the welding wire 10 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com