Energy-saving plastic extruder

A plastic extruder and barrel technology, applied in the field of plastic thermal processing equipment, can solve the problems of barrel blockage, large rotational torque, and slow extrusion speed of molten plastic, so as to prolong the life of the whole machine, save heat energy, and reduce rotation. The effect of torque requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

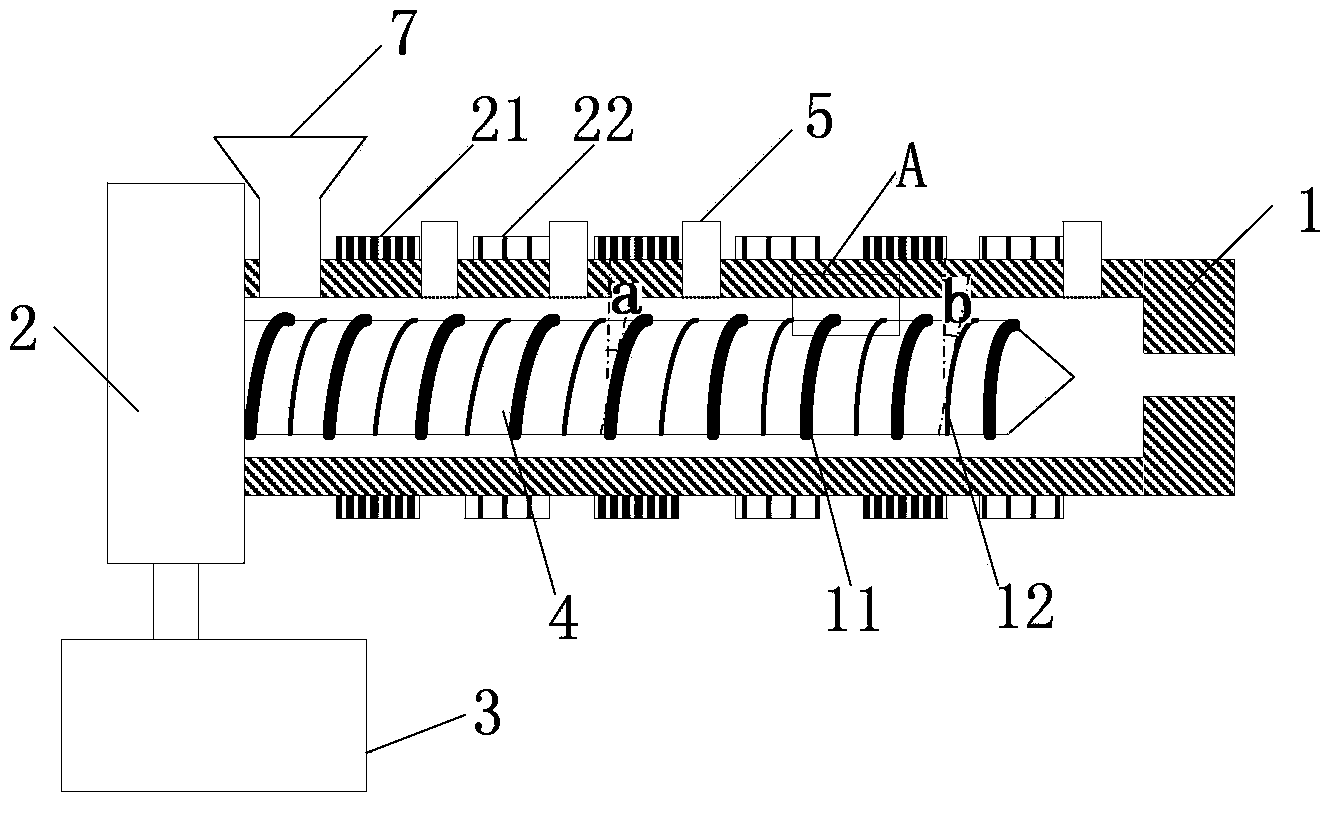

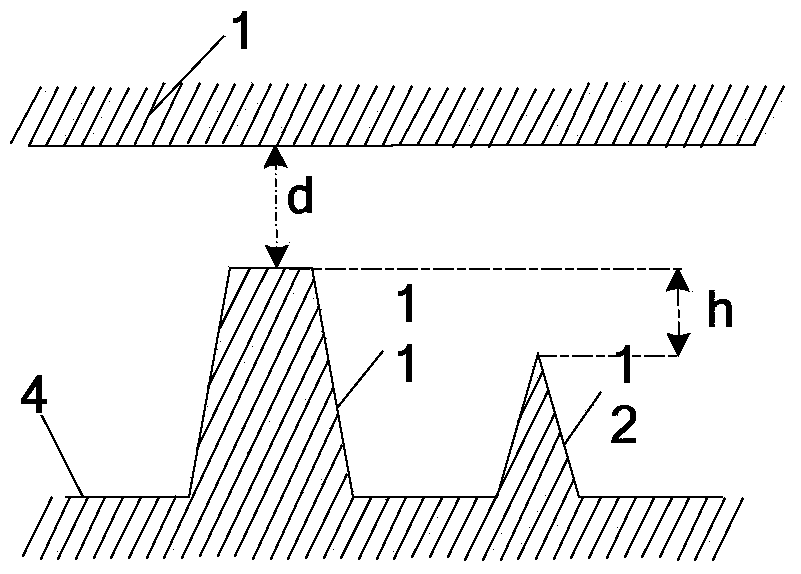

[0021] See figure 1 and figure 2 , An energy-saving plastic extruder of this embodiment includes a barrel 1, a drive motor 3 and a reducer 2, and a screw 4 is arranged inside the barrel, and the screw 4 can rotate in the barrel. The outer periphery of the barrel 1 is provided with a heater for heating and melting the plastic entering the barrel 1, the heater includes a plurality of first heaters 21 and a plurality of second heaters 22, the first heater 21 and the The second heaters 22 are arranged at intervals, and the temperature of the second heaters 22 is lower than the temperature of the first heaters 21 . That is, one or more second heaters 22 are provided between every two first heaters 21, which can not only ensure the heating and melting of plastic materials, but also minimize unnecessary heat energy consumption, which is more energy-saving and environment-friendly. The screw 4 includes a main thread 11 and a secondary thread 12 arranged in the thread pitch of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com