Face forming 3D printing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

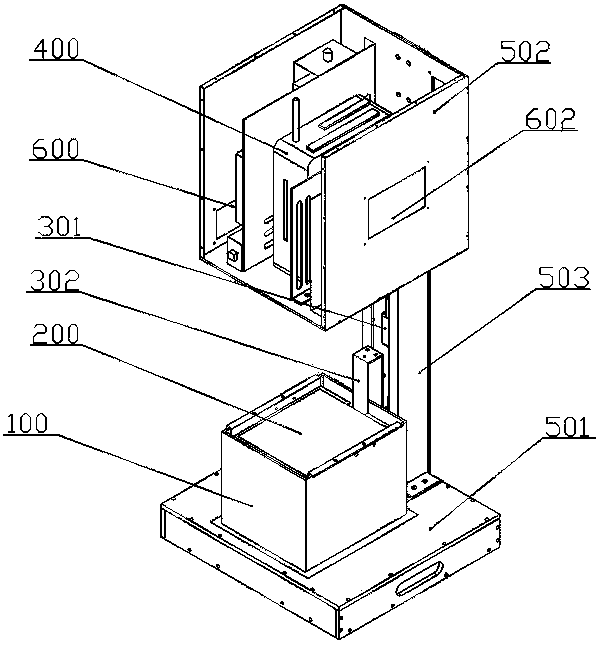

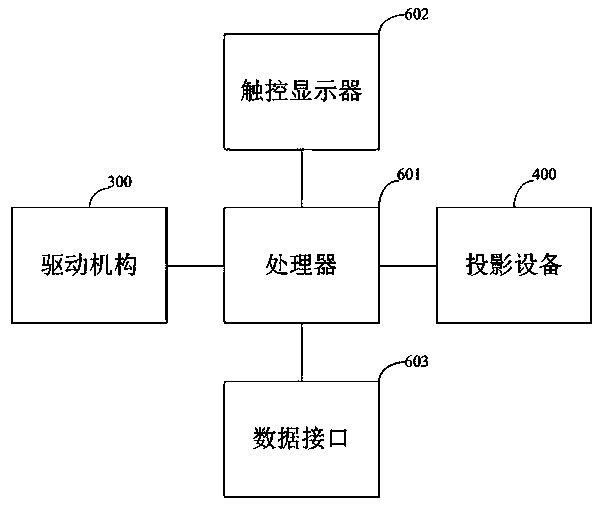

[0023] A surface forming 3D printing device mainly includes a liquid tank 100 , a processing platform 200 , a driving mechanism 300 and a projection device 400 . The liquid storage tank 100 holds the liquid photocurable material for preparing the product, such as photosensitive resin; the processing platform 200 is a molding support platform for the product, and it has a working position located in the liquid storage tank; the driving mechanism is used to drive the processing platform 200 in the storage The liquid tank moves up and down; the projection lens of the projection device 400 is located above the processing platform, and is used to project a projection image to the processing platform 200 . When printing, a suitable amount of liquid light-curing material is filled in the liquid storage tank 100, and then the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com