Double differential electromechanical compound transmission for tracked vehicles

A technology of electromechanical compound transmission and double differential, which is applied in the direction of tracked vehicles, control devices, vehicle components, etc., can solve problems such as the difficulty of further increasing the power density of the transmission system, achieve reduced technical risks, simple structure, and improve transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

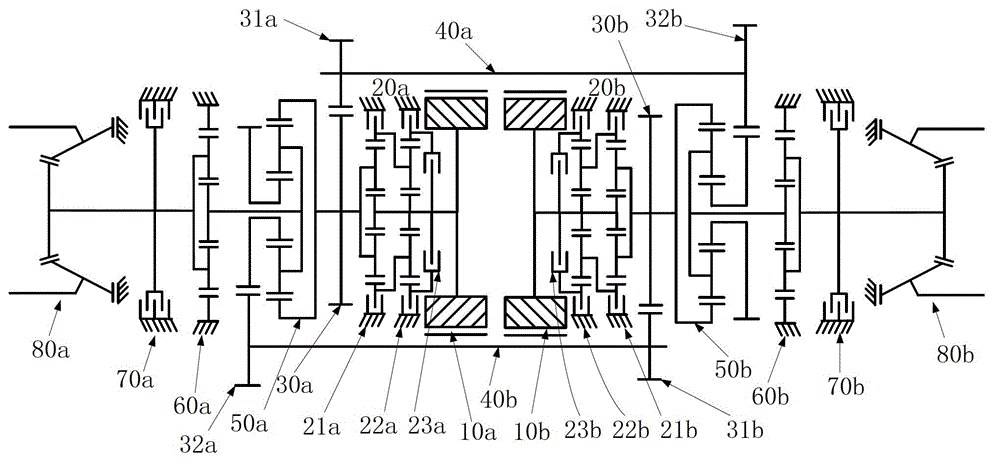

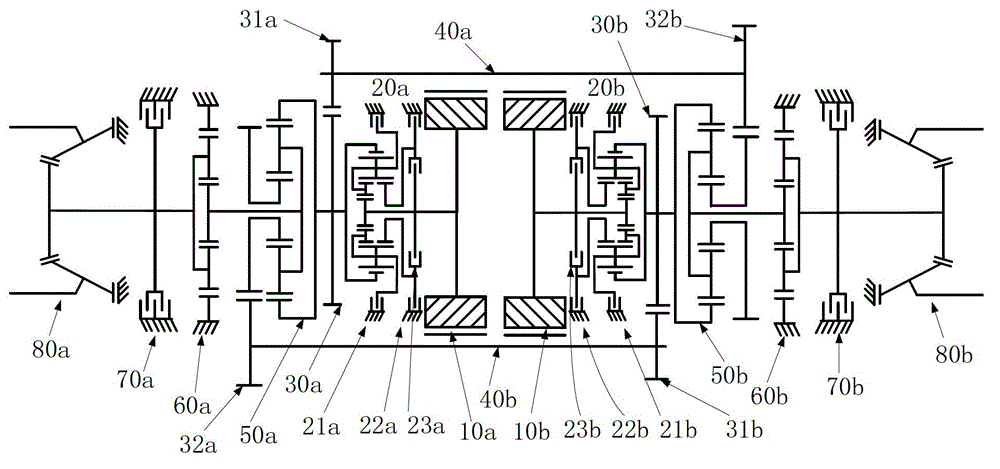

[0016] See attached figure 1 , a kind of double differential electromechanical compound transmission device for crawler vehicles, it comprises: left side drive motor 10a, left side three-speed planetary transmission mechanism 20a, left side one-speed brake 21a, left side two-speed brake 22a, left side three-speed Gear clutch 23a, left ring gear connecting gear 30a, left zero shaft connecting gear 31a, left sun gear connecting gear 32a, upper zero shaft 40a, left bus bar 50a, left decelerating planetary row 60a, left main brake 70a, left transmission 80a, right drive motor 10b, right third gear planetary transmission mechanism 20b, right first gear brake 21b, right second gear brake 22b, right third gear clutch 23b, right ring gear connecting gear 30b, right zero shaft connection gear 31b, right sun gear connection gear 32b, lower zero shaft 40b, right bus bar 50b, right deceleration planetary row 60b, right main brake 70b and right transmission 80b;

[0017] The output shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com