Sulfuric acid car tank car filling device

A technology for automobiles and tankers, which is applied in distribution devices, special distribution devices, liquid distribution, transportation or transfer devices, etc., can solve the problems of environmental pollution, brittle rubber pipes, acid leakage, burns, etc., and achieve no safety. The effect of hidden danger, novel structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

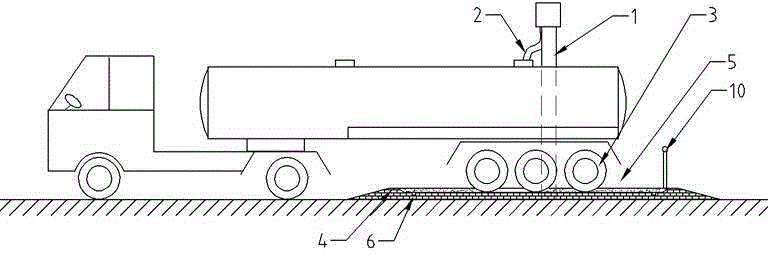

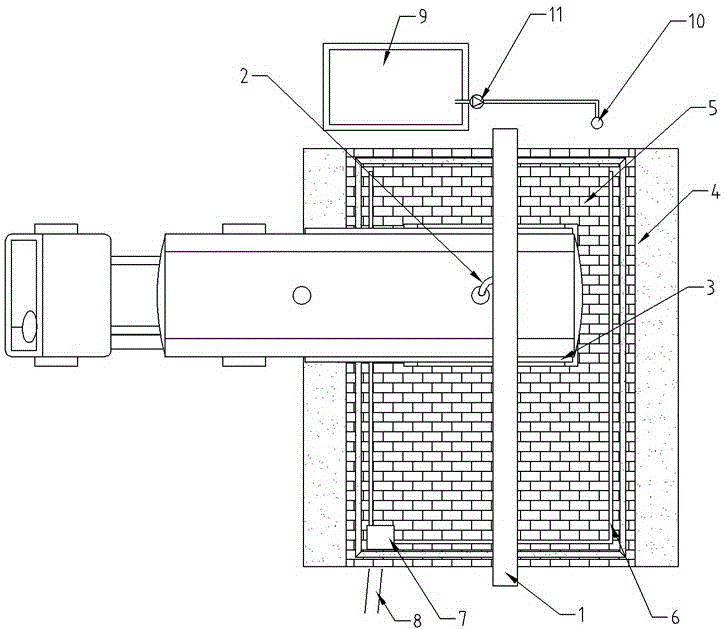

[0012] Such as figure 1 , figure 2 Shown, a kind of car tank car filling device of sulfuric acid is characterized in that its structure: comprises sulfuric acid storage tank, loading acid door bridge 1 and loading acid crane pipe 2; 3. A layer of acid-resistant floor tiles is paved in the parking area, and a low-slope retaining wall 4 is built around the parking area of the rear wheel 3 of the automobile tanker to form a square pool 5; the cross-section of the low-slope retaining wall 4 is trapezoidal; An acid collection groove 6 is provided on the 4 sides of the surrounding low-slope retaining walls, and an acid collection groove 7 is designed at one corner of the square pool 5. The acid collection groove 7 communicates with the above-mentioned acid collection groove 6, and the acid collection groove 7 passes through The discharge por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com