Treatment method for reducing ammonia nitrogen concentration of wastewater containing ammonium perchlorate

A technology of ammonium perchlorate and ammonia nitrogen concentration, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve problems such as failure to meet discharge standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

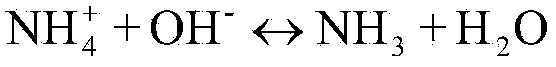

Method used

Image

Examples

Embodiment 1

[0023] This embodiment is a treatment method for reducing the concentration of ammonia nitrogen in wastewater containing ammonium perchlorate.

[0024] The quality of wastewater in this embodiment: the concentration of ammonia nitrogen is 556mg / L. The specific process is:

[0025] Step 1, the adjustment of pH value. The ammonium perchlorate-containing wastewater is pumped into a pH adjustment pool, and a 10% NaOH solution is added to adjust the pH of the ammonium perchlorate wastewater to 12.5.

[0026] Preparation of 10% NaOH solution: first add about 70L of tap water into a white PE barrel with a volume of 100L, then add 7.94kg of NaOH solid, and obtain a 10% NaOH solution after it is completely dissolved.

[0027] Step 2, air blow off. Ammonium perchlorate wastewater with a pH value of 12.5 in 2m 3 The flow rate of / h is pumped into the stripping tower for stripping. The stripping tower is equipped with polypropylene Pall ring packing. While pumping ammonium perchlorat...

Embodiment 2

[0033] This embodiment is a treatment method for reducing the concentration of ammonia nitrogen in wastewater containing ammonium perchlorate.

[0034] The wastewater quality of this embodiment: the concentration of ammonia nitrogen is 119.2mg / L. The specific process is:

[0035] Step 1, adjust the pH value. Pump the ammonium perchlorate-containing wastewater into the pH adjustment tank, add a 10% NaOH solution, and adjust the pH of the ammonium perchlorate wastewater to 13.

[0036] Step 2, air blow off. The ammonium perchlorate wastewater with a pH value of 13 was treated with 1.5m 3 The flow rate of / h is pumped into the stripping tower for stripping. The stripping tower is equipped with a 4.38-meter-high polypropylene Pall ring packing. When ammonium perchlorate wastewater is pumped into the stripping tower, air is introduced into the stripping tower at the same time. The air flow rate is 1.38m / s. The ammonium ion in the ammonium perchlorate wastewater is converted in...

Embodiment 3

[0041] This embodiment is a treatment method for reducing the concentration of ammonia nitrogen in wastewater containing ammonium perchlorate.

[0042] The quality of wastewater in this embodiment: the concentration of ammonia nitrogen is 1101.9 mg / L. The specific process is:

[0043] Step 1, adjust the pH value. The wastewater containing ammonium perchlorate is pumped into a pH value adjustment tank, and a NaOH solution with a mass concentration of 10% is added to adjust the pH value of the ammonium perchlorate wastewater to 13.

[0044] Step 2, air blow off. The ammonium perchlorate wastewater with a pH value of 13 was treated with 1.4m 3 The flow rate of / h is pumped into the stripping tower for stripping. The stripping tower is equipped with a 4.38-meter-high polypropylene Pall ring packing. When ammonium perchlorate wastewater is pumped into the stripping tower, air is introduced into the stripping tower at the same time. The air flow rate is 1.35m / s. The ammonium io...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com