Treatment technology of comprehensive wastewater produced by engine manufacturing

A technology for treating and integrating wastewater, applied in biological water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the complex multi-stage treatment process, unstable effluent quality and large consumption of chemicals and other problems to achieve the effect of preventing the formation of the filter cake layer, excellent anti-blocking and anti-pollution ability, and delaying the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

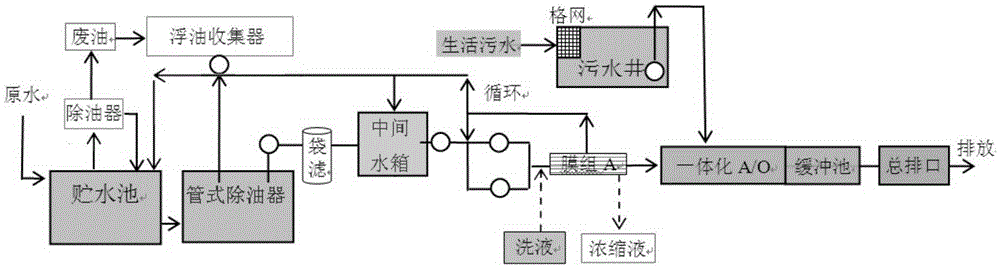

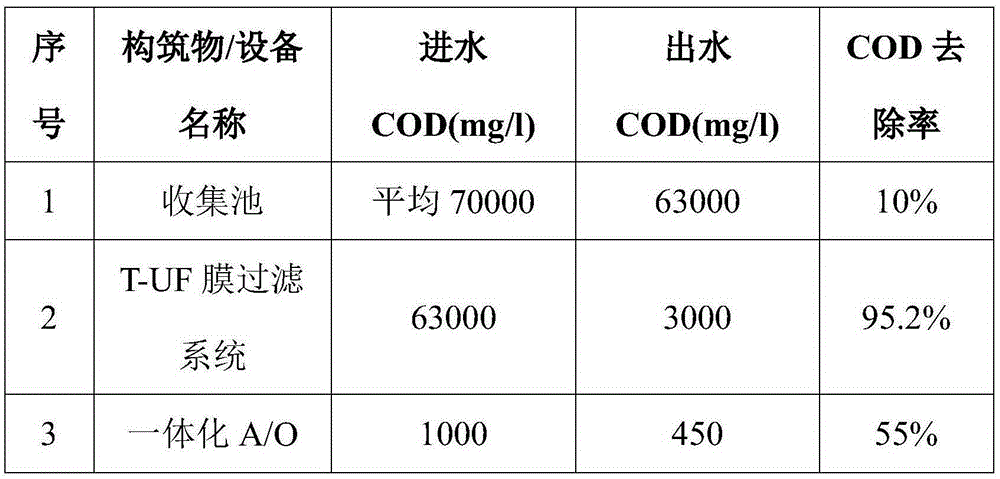

[0037] A treatment process for comprehensive waste water produced by engine manufacturing, comprising the following steps:

[0038] (1) The comprehensive wastewater is discharged from the workshop to the sewage treatment station with pressure flow, and then enters the storage tank of the sewage treatment station for water quality adjustment. The longer hydraulic retention time HRT is 10-12h;

[0039] (2) Set up a degreaser to separate part of the free slick oil, and the oil is collected to the oil slick collector through the pipeline, and then recycled by a qualified unit after collection.

[0040] (3) The wastewater treated in step (2) is lifted into the tubular degreaser through the lifting pump, and the fine oil slick and most of the suspended matter in the wastewater are further removed through the tubular degreaser; the tubular degreaser adopts The steel tank body is set as an inclined tube to improve the oil removal efficiency. The surface load rate of the tubular degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com