W-type ferrite absorbent for millimeter waves

A ferrite and millimeter wave technology, applied in other chemical processes, chemical instruments and methods, etc., can solve problems such as the need for further improvement of microwave absorption performance, failure to meet high loss, and influence of microwave absorption performance, etc., to achieve operational and technological processes Simple and pollution-free, excellent wave-absorbing performance, and the effect of large molecular magnetic moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

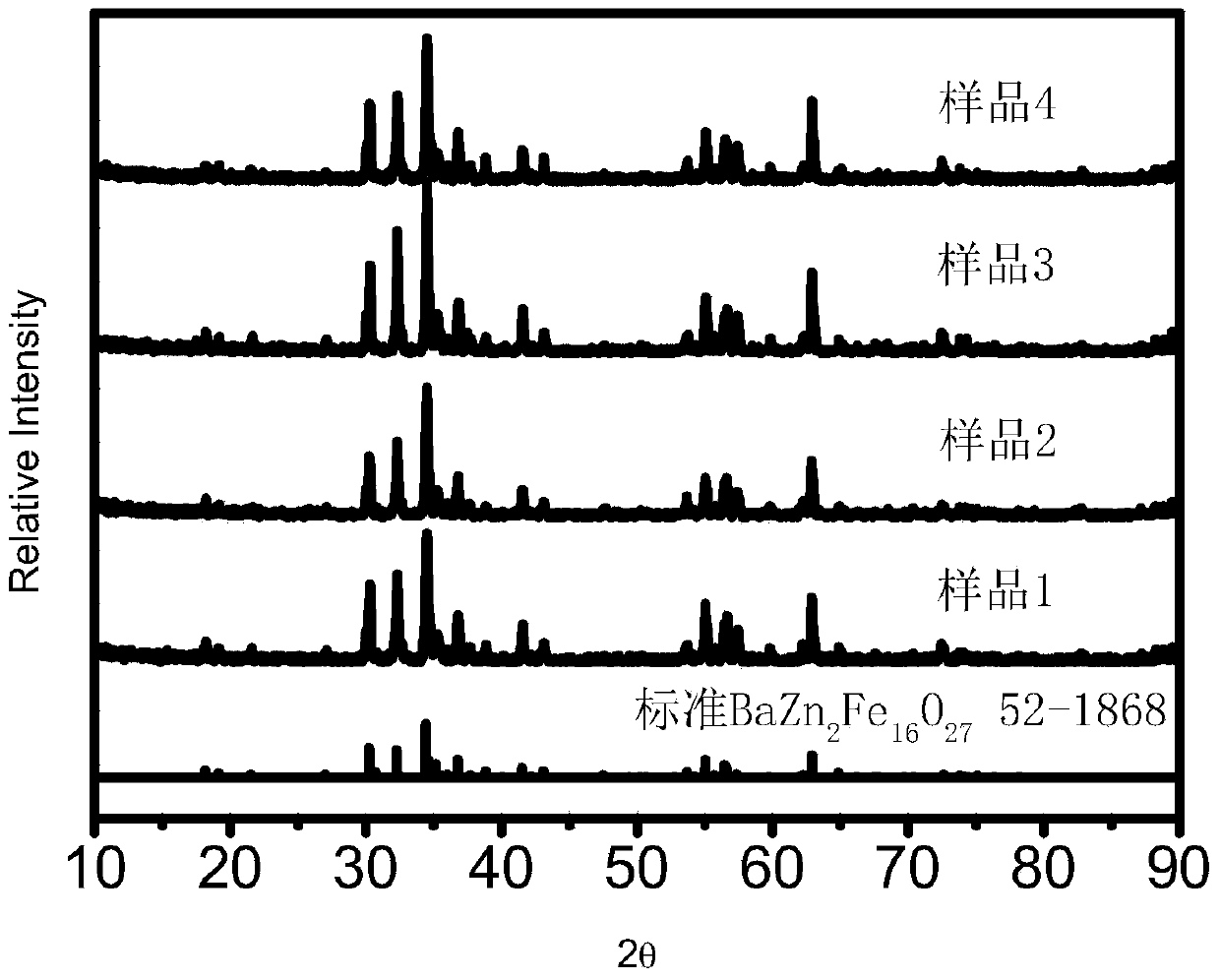

[0021] A W-type ferrite absorber for millimeter waves, the content (mass percentage) of each component of the W-type ferrite material is calculated as:

[0022] BaCO 3 : 11.86wt%, Co 2 o 3 : 1.05wt%, ZnO: 10.01wt%, Fe 2 o 3 : 77.08wt%

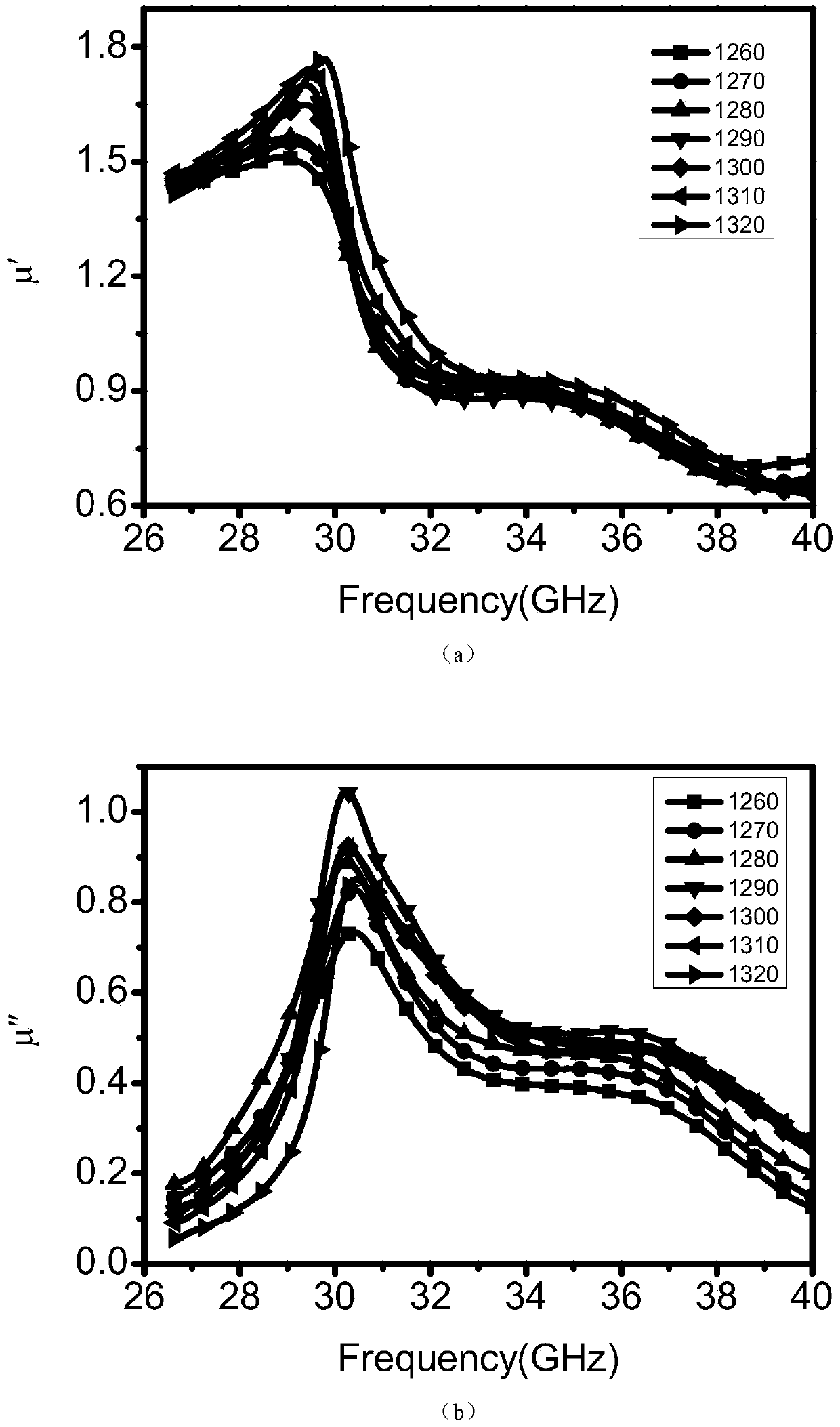

[0023] It is prepared by the traditional solid-state reaction method, the pre-calcination temperature is 1290°C, and the sintering temperature is 1280°C.

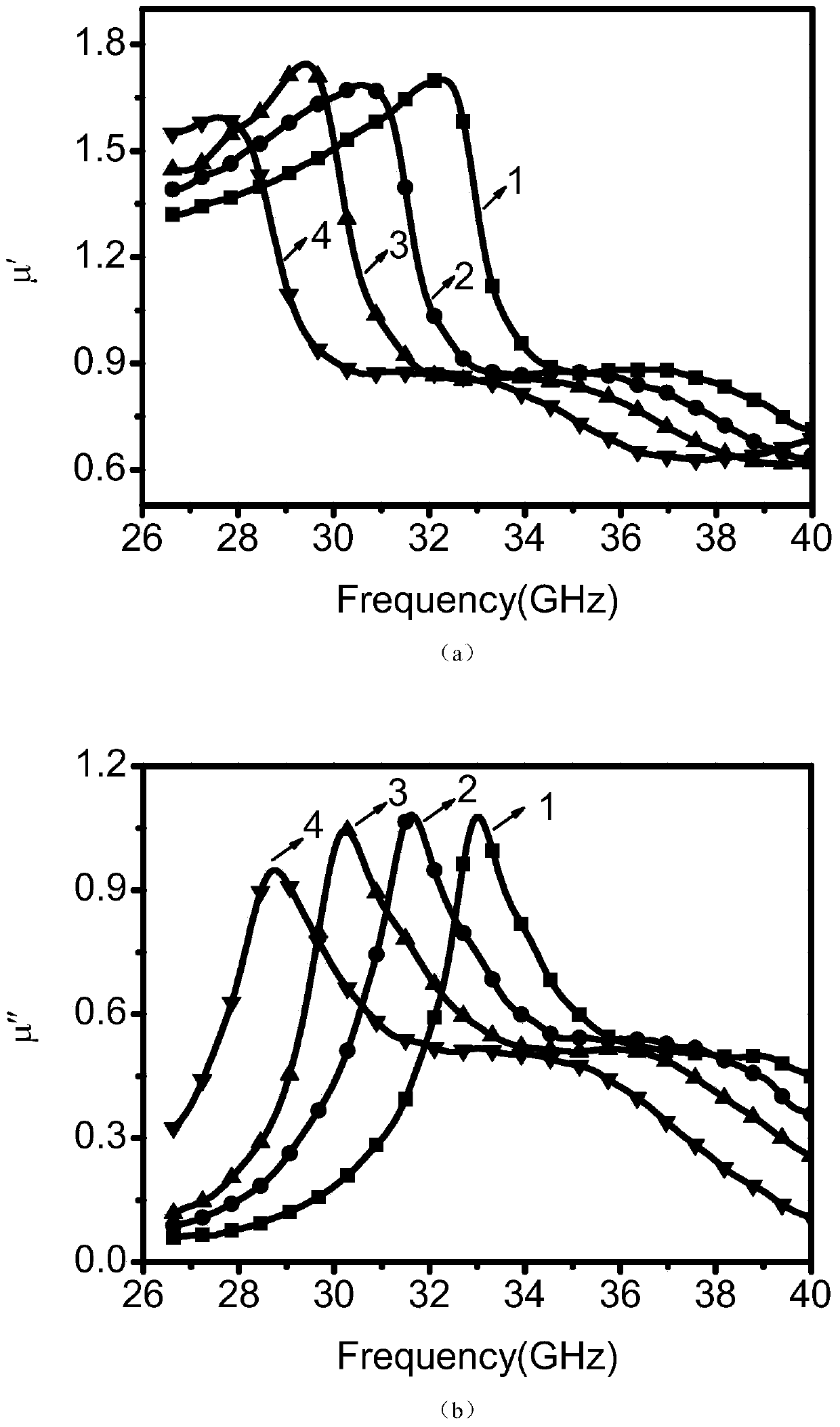

[0024] The electromagnetic parameter test of the prepared W-type ferrite absorber (sample 1) shows that the natural resonance frequency of the ferrite absorber is 33.1GHz, and the peak values of the real and imaginary parts of the magnetic permeability are 1.70 and 1.07, respectively. .

Embodiment 2

[0026] A W-type ferrite absorber for millimeter waves, the content (mass percentage) of each component of the W-type ferrite material is calculated as:

[0027] BaCO 3 : 12.08wt%, Co 2 o 3 : 1.51wt%, ZnO: 9.12wt%, Fe 2 o 3 : 77.29wt%

[0028] It is prepared by the traditional solid-state reaction method, the pre-calcination temperature is 1290°C, and the sintering temperature is 1280°C.

[0029] The electromagnetic parameter test of the prepared W-type ferrite absorber (sample 2) shows that the natural resonance frequency of the ferrite absorber is 31.6GHz, and the peak values of the real and imaginary parts of the magnetic permeability are 1.68 and 1.08, respectively. .

Embodiment 3

[0031] A W-type ferrite absorber for millimeter waves, the content (mass percentage) of each component of the W-type ferrite material is calculated as:

[0032] BaCO 3 : 12.29wt%, Co 2 o 3 : 2.03wt%, ZnO: 8.21wt%, Fe 2 o 3 : 77.47wt%

[0033] It is prepared by the traditional solid-state reaction method, the pre-calcination temperature is 1290°C, and the sintering temperature is 1280°C.

[0034] The electromagnetic parameter test of the prepared W-type ferrite absorber (sample 3) shows that the natural resonance frequency of the ferrite absorber is 30.2GHz, and the peak values of the real and imaginary parts of the magnetic permeability are 1.74 and 1.04, respectively .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Absorption bandwidth | aaaaa | aaaaa |

| Absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com