Method for comprehensively extracting dihydromyricetin and polysaccharide in vine tea at low temperature

A dihydromyricetin, comprehensive extraction technology, applied in the direction of organic chemistry, to achieve the effect of good color, lower extraction temperature, and shorten extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

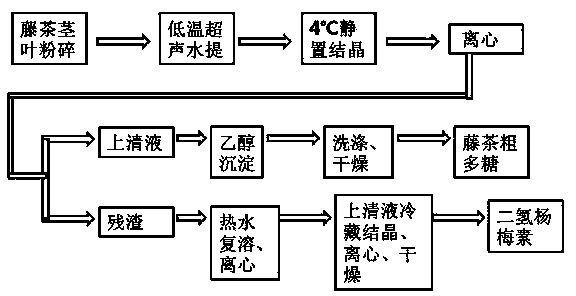

Image

Examples

Embodiment 1

[0023] Example 2:

[0024] (1) Fresh vine tea stems and leaves are fully dried, then crushed until they pass through a 40-mesh sieve, and 100g is accurately weighed.

[0025] (2) Add 3L of water at 50°C, stir for 3-5min under heat preservation to disperse the material evenly in the water, then turn on the ultrasonic wave, the ultrasonic power is 800W, after ultrasonication for 20min, let the material mixture cool naturally, then place it at 4°C for 12- After 24 hours, the flavonoids (mainly composed of dihydromyricetin) in the solution were crystallized.

[0026] (3) The mixture was centrifuged, and the supernatant was the extract of vine tea polysaccharides, concentrated by rotary evaporation to 500mL-600mL, added 3 times of absolute ethanol to precipitate, stood at 4°C for 4 hours, then suction filtered and washed with absolute ethanol, After the filter residue is dried, the crude polysaccharide of vine tea is obtained, and the yield is about 5%-7%.

Embodiment 2

[0028] Example 3

[0029] (1) Fresh vine tea stems and leaves are fully dried, then crushed until they pass through a 40-mesh sieve, and 100g is accurately weighed.

[0030] (2) Add 3L of water at 60°C, stir for 3-5 minutes under heat preservation to disperse the material evenly in the water, and then turn on the ultrasonic wave with an ultrasonic power of 600W. After 24 hours, the flavonoids (mainly composed of dihydromyricetin) in the solution were crystallized.

[0031] (3) The mixture was centrifuged, and the supernatant was the extract of vine tea polysaccharides, concentrated by rotary evaporation to 500mL-600mL, added 4 times of 95% ethanol for precipitation, left standing at 4°C for 4h, suction filtered and washed with absolute ethanol, After the filter residue is dried, the crude polysaccharide of vine tea is obtained, and the yield is about 5%-8%.

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com