Light source containing internal light distribution curve

A light distribution and curve technology, which is applied in the field of light sources with internal light distribution curves, can solve the problems of glare, large light pollution, small cut-off angle, zebra effect, etc., and achieve the effects of improving the life of the light source, improving the reflectivity, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

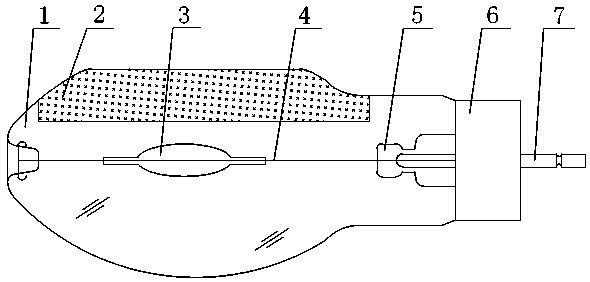

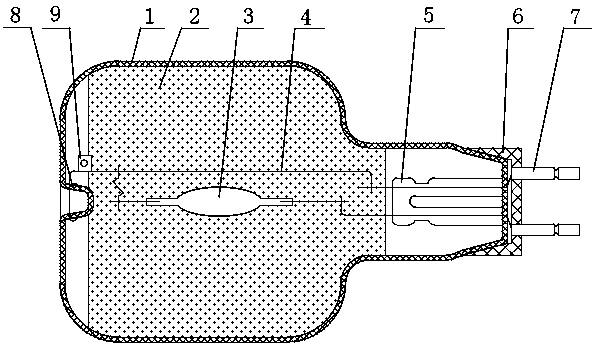

[0017] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] The illuminant adopts the ion luminescent ball 3 .

[0019] The lamp cap is a screw lamp cap 10 or a ceramic seat 6 fixed with two metal rods 7 .

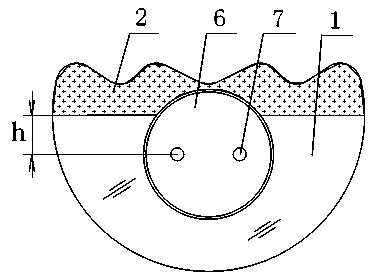

[0020] There is a recessed pillar 8 on one end of the inside of the glass bulb 1, and the lamp cap at the other end is a conventional screw lamp cap 10, or a ceramic seat 6 with two metal rods 7, and the lower surface is a conventional smooth arc surface, that is, the light source transmission area. The shape of the traditional upper surface has been greatly improved. The upper surface is a regular wavy arc surface, which is symmetrical to the center of the transmission area, and the light-transmitting surface and the reflecting surface are enlarged.

[0021] On the inner surface of the wavy arc of the glass bulb 1, a layer of reflective film is sprayed, that is, the reflective coating 2 mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com