An olfactory simulation instrument and an on-site analysis method for the gas (smell) taste level of specific substances

An instrument and olfactory technology, applied in the field of olfactory simulation instruments and on-site analysis of gas (smell) taste grades of specific substances, can solve problems such as response differences, and achieve the effects of large gas-liquid ratio, comprehensive feature extraction, and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The present invention will be described in further detail below in conjunction with the accompanying drawings.

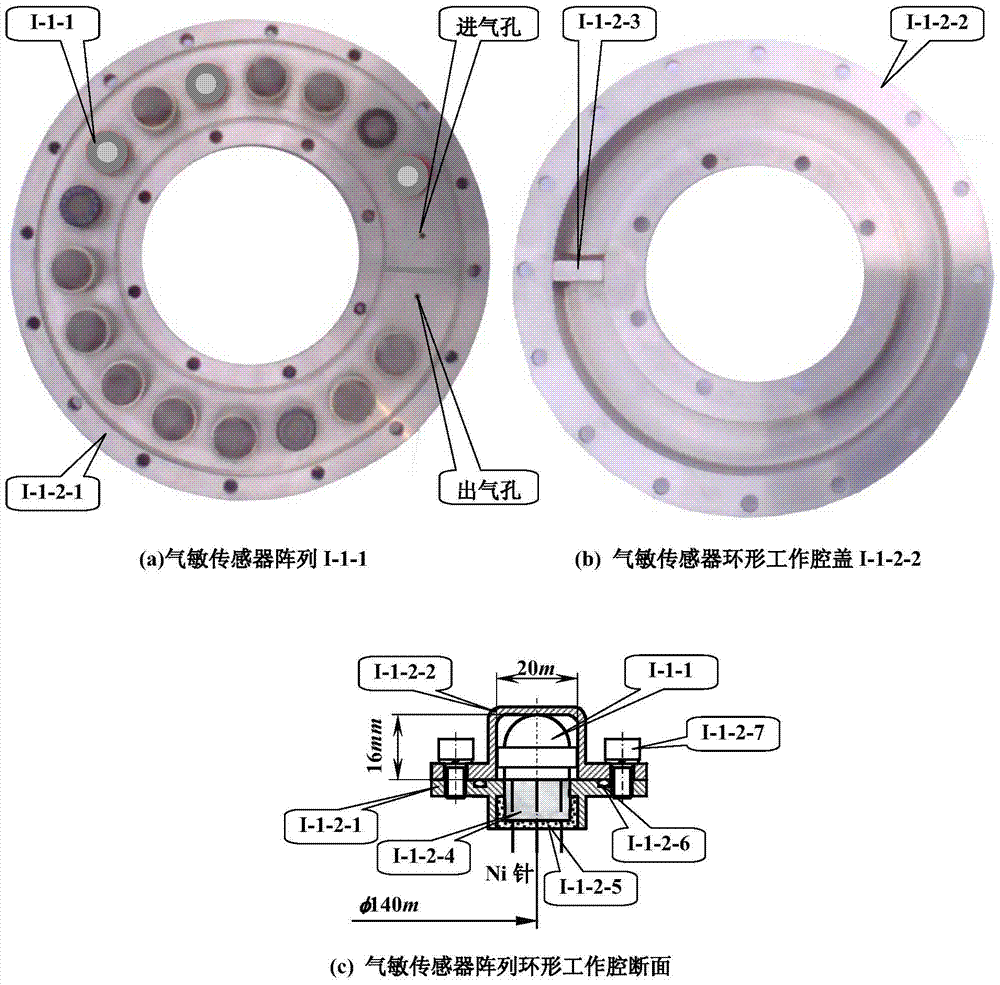

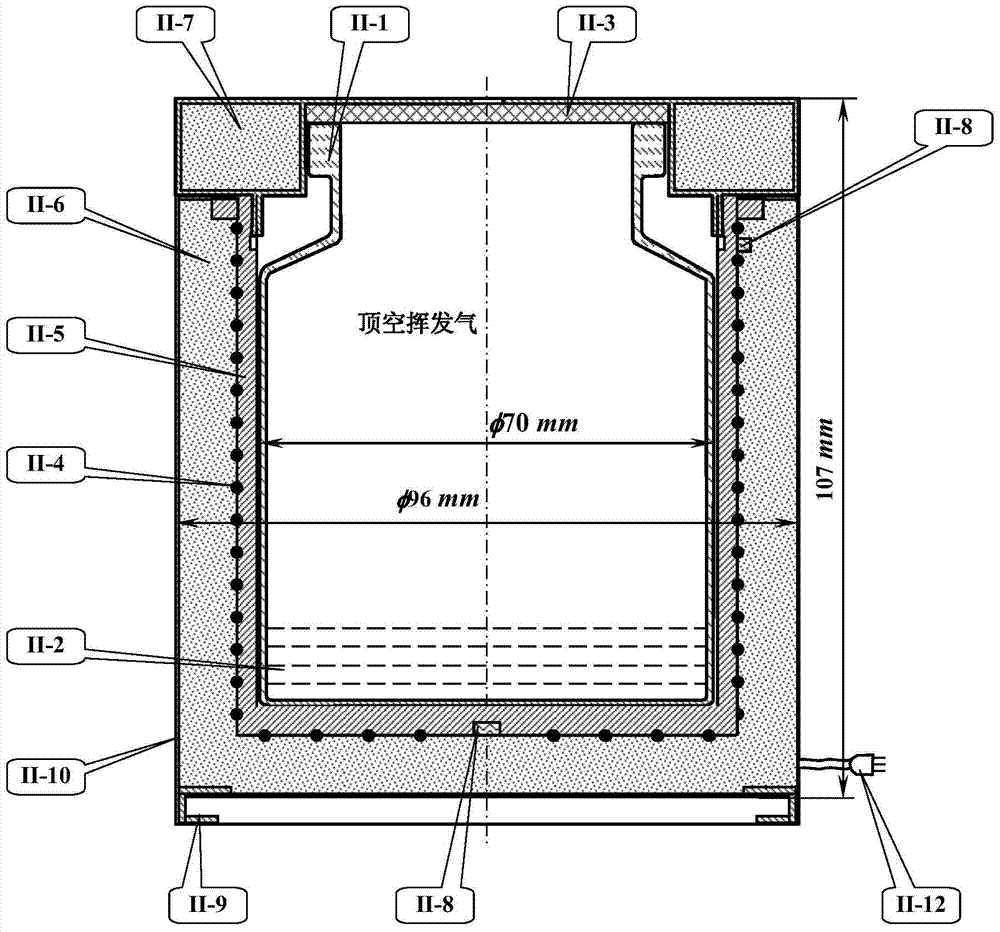

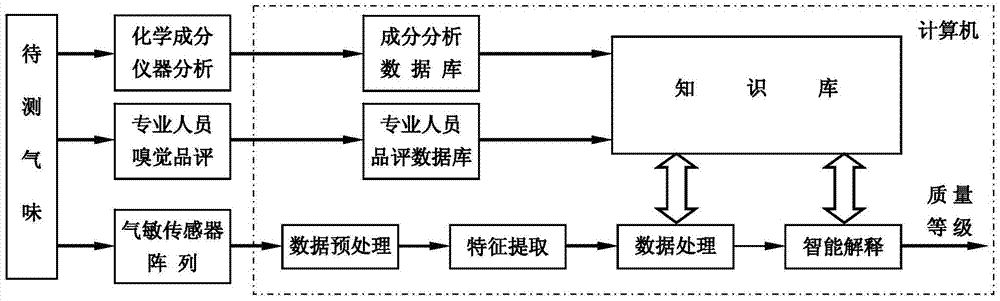

[0100] figure 1 It is the present invention-a kind of olfactory simulation instrument-basic principle block diagram. The instrument uses multiple gas sensors with overlapping performance to form an array to imitate a large number of olfactory receptor cells in the human nose, uses pattern classification and prediction models to simulate human logic and image thinking, and combines precision testing technology, computer technology, multivariate analysis and various An intelligent real-time olfactory simulation system is constructed with the technology in the specific field. In the learning stage, the olfactory simulation instrument tests the volatile gases in the headspace of various odorant samples with known odor (smell) and taste grades and categories, and obtains various traces and traces of the odor (smell) and taste one by one. The comprehensive sensit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com