Particle damping vibration attenuation design method for umbrella-type vibration of wheel structure

A particle damping and design method technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as high corresponding frequency, many influencing factors of particle damping, complex shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

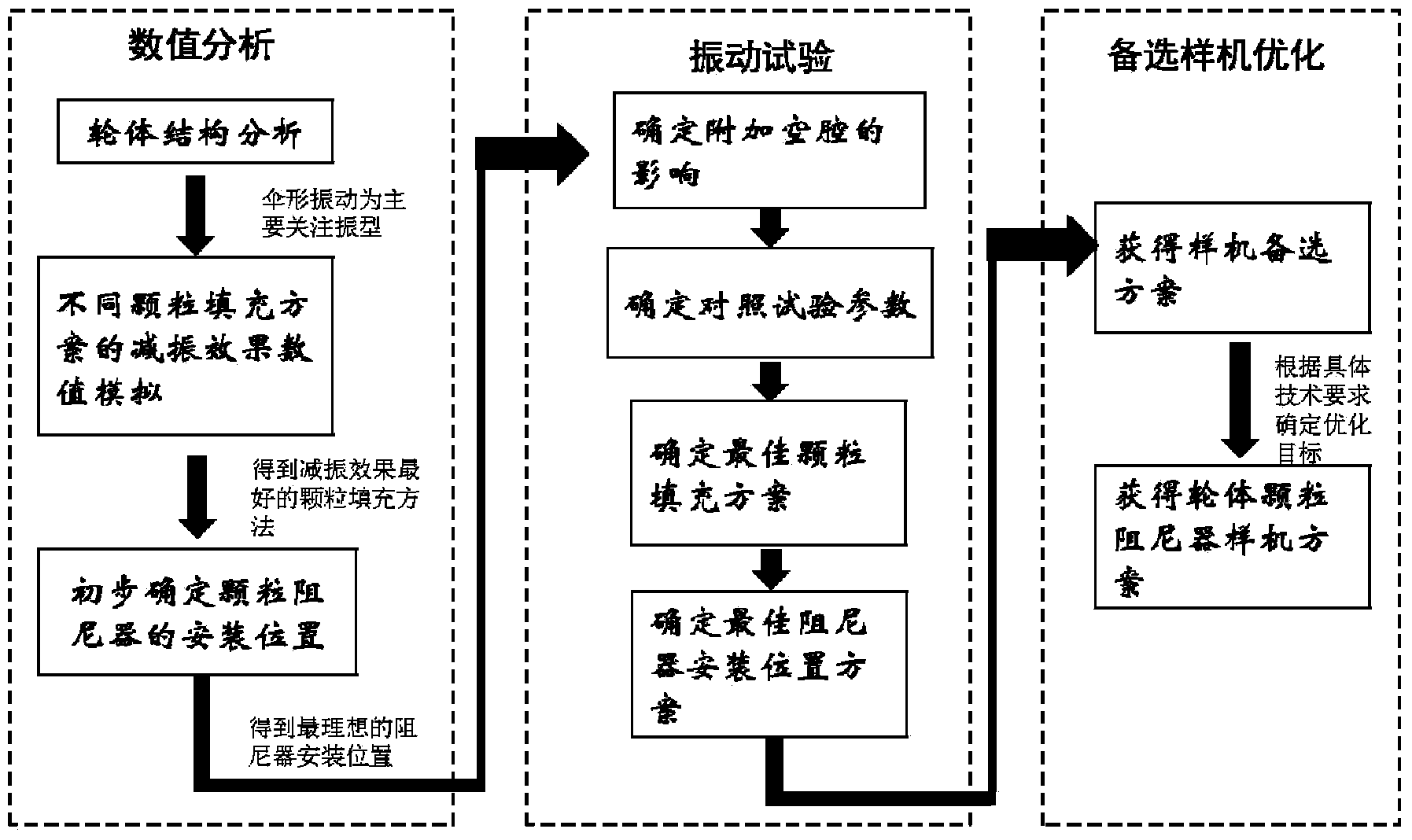

[0071] see image 3 The present invention is a particle damping design method for umbrella-shaped vibration of wheel structure. The specific steps are as follows:

[0072] Step 1: Build a solid model of the wheel body

[0073] Establish a finite element model of the target wheel in the CAE pre-processing software for the given entity model;

[0074] Step 2: Perform structural analysis on the established finite element model

[0075] First, import the established finite element model into the finite element software ANSYS, define the corresponding material parameters, given the speed and displacement constraints, and obtain the structural stress distribution caused by the centrifugal force through static analysis. Pay attention to the main stress of the wheel structure The location and level of the concentration point, the stress level of the wheel flange;

[0076] Secondly, the modal analysis of mass normalization is adopted to obtain the natural vibration characteristics of the wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com