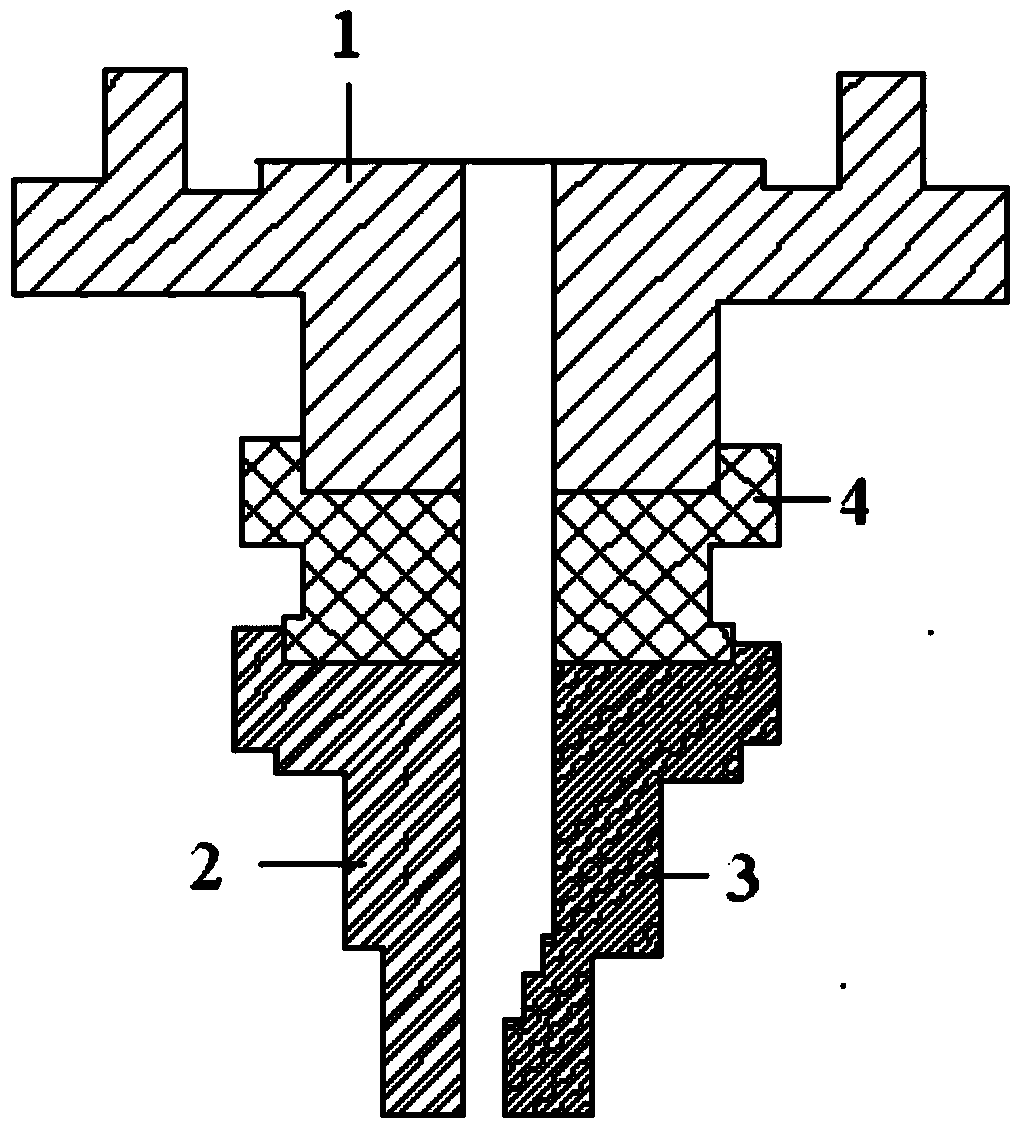

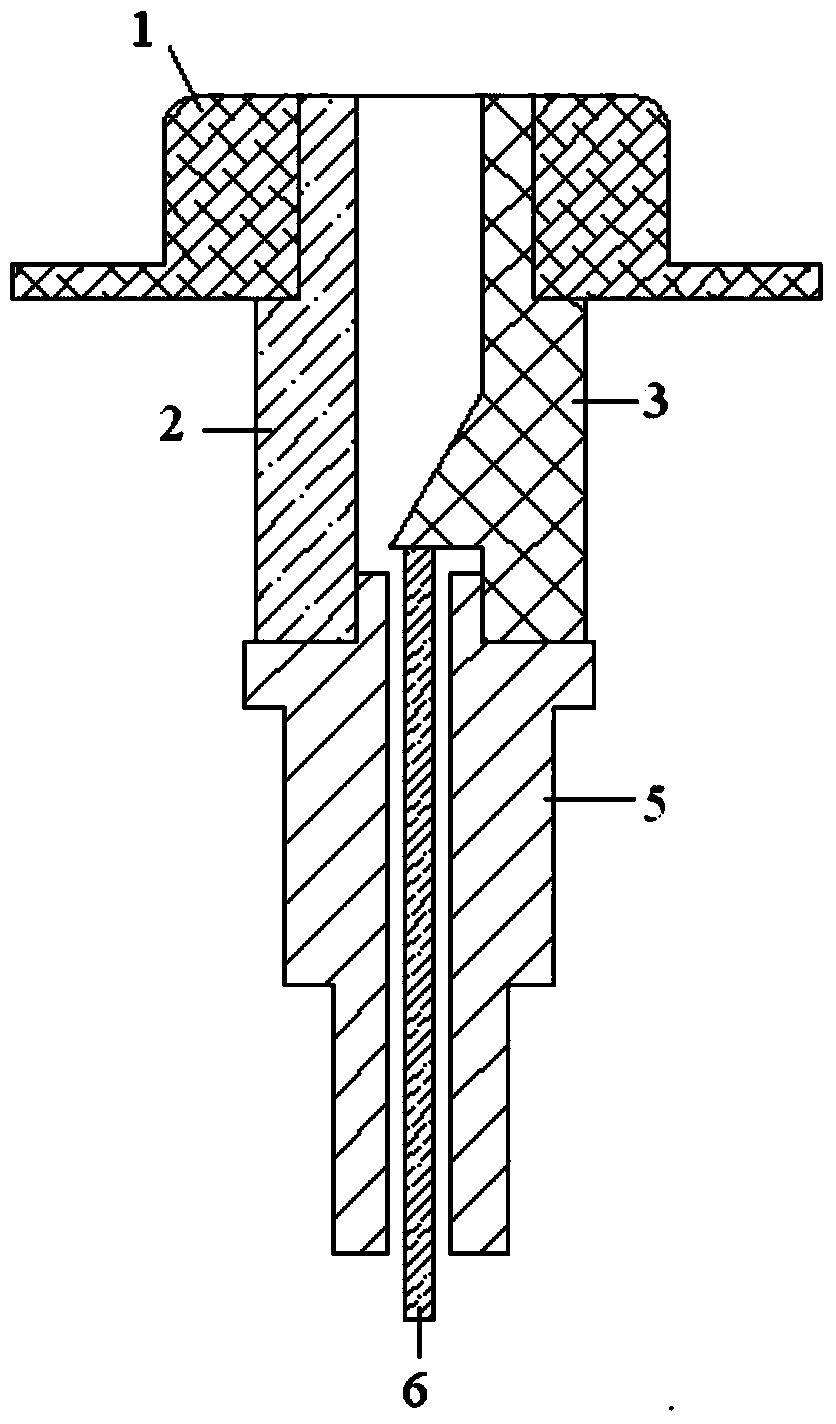

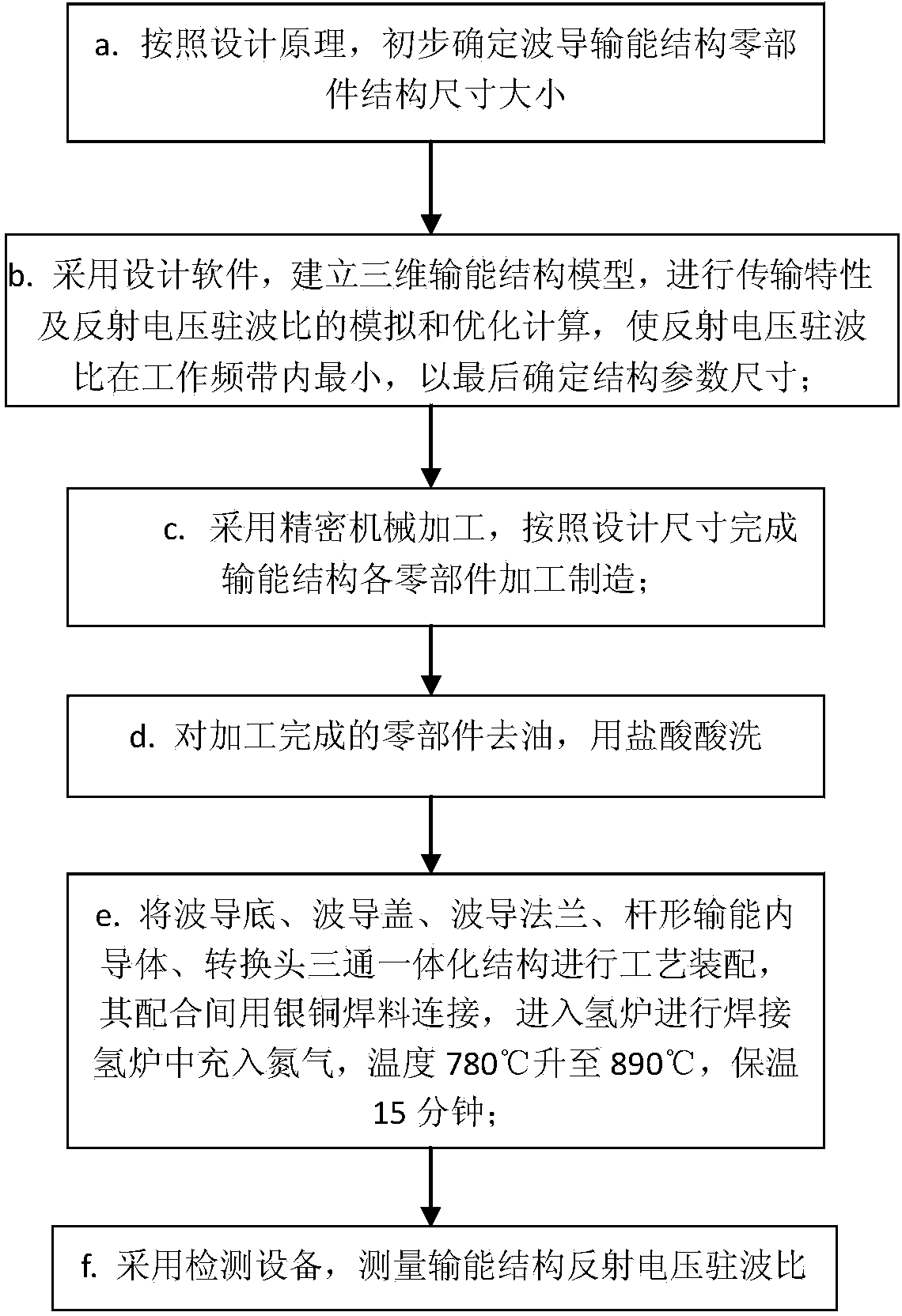

V-waveband traveling-wave tube energy transmission structure and manufacturing method thereof

A traveling wave tube and energy transmission technology, which is applied in the field of V-band traveling wave tube energy transmission structure and its manufacturing, can solve the problems of difficult processing of the bottom of the structural waveguide, influence on energy transmission power, non-integrated design, etc., and achieve improved electronic performance. Efficiency, Guaranteed Efficiency, Effect of Output Power Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The V-band traveling wave tube adopts the energy transmission structure described in the patent of the present invention. The experimental test results show that within the working bandwidth of 5 GHz, the traveling wave tube energy transmission reflected voltage standing wave ratio is less than 1.5, and the output power of the traveling wave tube exceeds 20W. The tube efficiency exceeds 20%, which ensures the realization of the V-band traveling wave tube efficiency tabulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com