Non-combustible secondary lithium battery

A secondary lithium battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of limited improvement and difficult performance of graphite, and achieve high safety and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: A button battery composed of a phosphonate non-combustible electrolyte and a silicon-based negative electrode

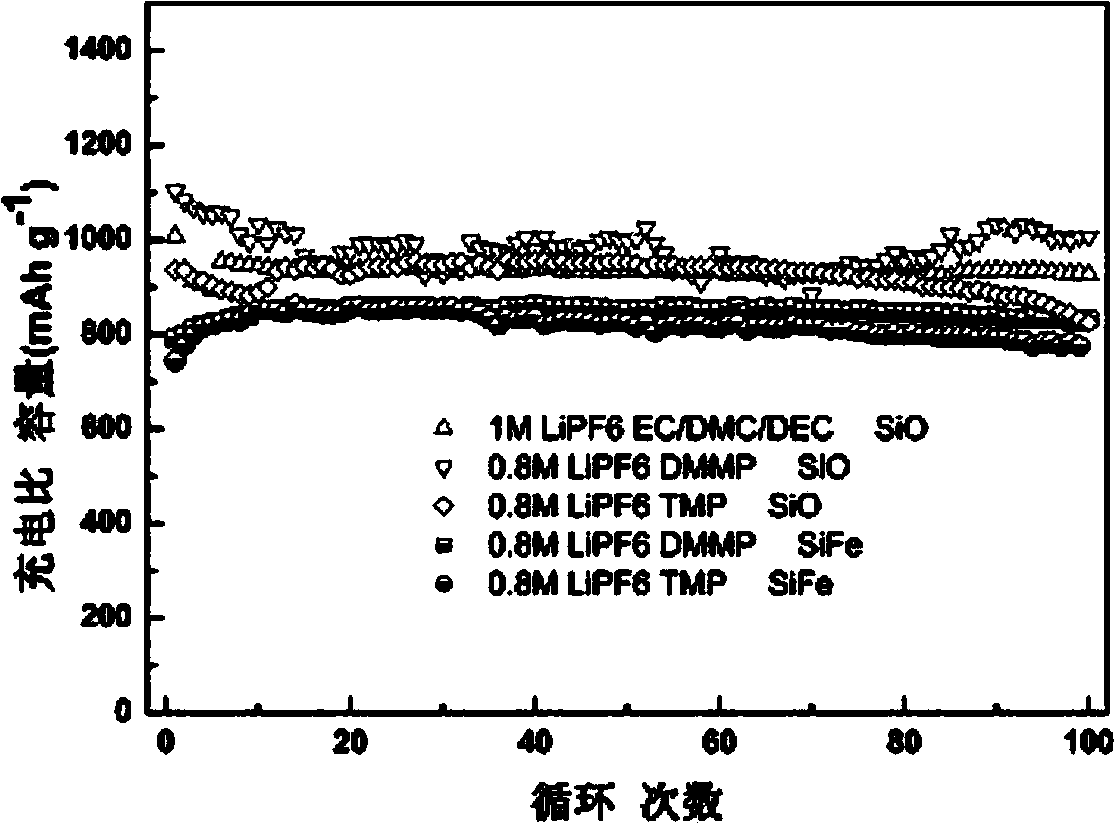

[0028] Assemble SiO / Li, SiFe / Li, Si / Li button cells in a glove box filled with argon, using electrolyte prepared by phosphonate, using constant current charge and discharge mode, working voltage range is 0.01 ~ 1.5V, The current density is 100mA / g. see test results figure 2 , the results show that the SiO negative electrode exhibits good cycle stability in phosphonate non-combustible electrolytes, among which DMMP and TMP have high cycle stability, and the capacity retention rates after 100 cycles are 91.4% and 88.2%, respectively, very Close to the cycle performance in carbonate-based electrolytes. It shows that these non-combustible electrolytes have better electrochemical stability to SiO materials, and the phosphonate non-combustible electrolytes have a great possibility of application on SiO electrodes. After 100 cycles of cycling in DMMP a...

Embodiment 2

[0029] Example 2: A button battery composed of phosphonate non-combustible electrolyte and antimony-based negative electrode

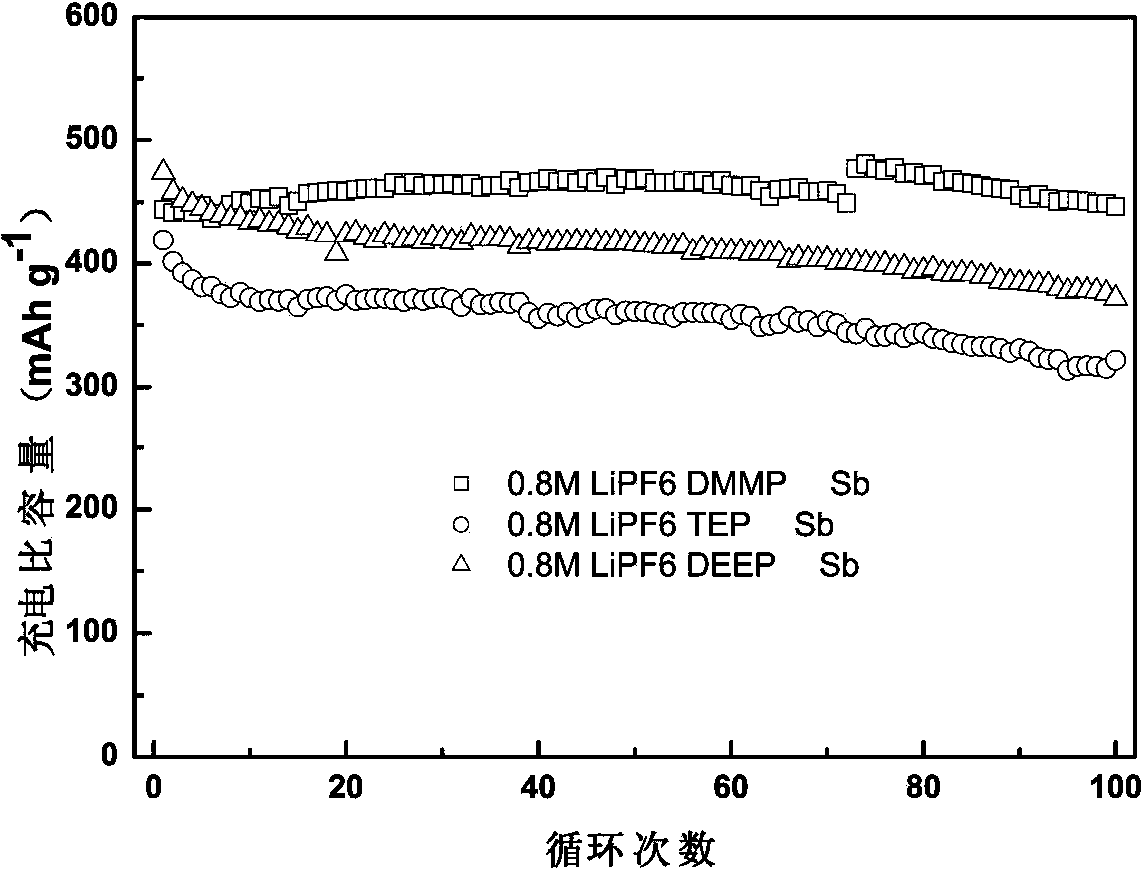

[0030] The Sb / Li2016 button cell was assembled in a glove box filled with argon, using the electrolyte prepared by phosphonate, using the constant current charge and discharge mode, the working voltage range was 0.4-1.5V and the current density was 100mA / g. see test results image 3 , the results showed that Sb / C showed good electrochemical activity in several phosphonate non-combustible electrolytes, and the charging specific capacity in the first week was above 400mAh / g, especially in DMMP, DEEP and TEP non-combustible electrolytes. The solution showed high cycle stability, and the capacity retention rates after 100 weeks were 100.1%, 76.8% and 78.4%, respectively. This expands the application of phosphonate-based nonflammable electrolytes in alloy anodes.

Embodiment 3

[0031] Example 3: A button battery composed of phosphonate non-combustible electrolyte and tin-based negative electrode

[0032]Assemble Sn / Li2016 button cells in a glove box filled with argon, using the electrolyte prepared by dimethyl methylphosphonate (DMMP), using constant current charge and discharge mode, the working voltage range is 0.01 ~ 2V, the current density It is 100mA / g. The test results show that the discharge specific capacity of Sn-based material in DMMP electrolyte is 1305mAh / g in the first week, the coulombic efficiency is 61.6%, and the capacity retention rate after 100 cycles is 46.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com