Cable extraction electrode and punch die and machining method for cable extraction electrode

A technology for leading out electrodes and cables, applied in the direction of multi-core cable end parts, circuits, electrical components, etc., can solve problems such as deformation, and achieve the effects of long service life, stable shape, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

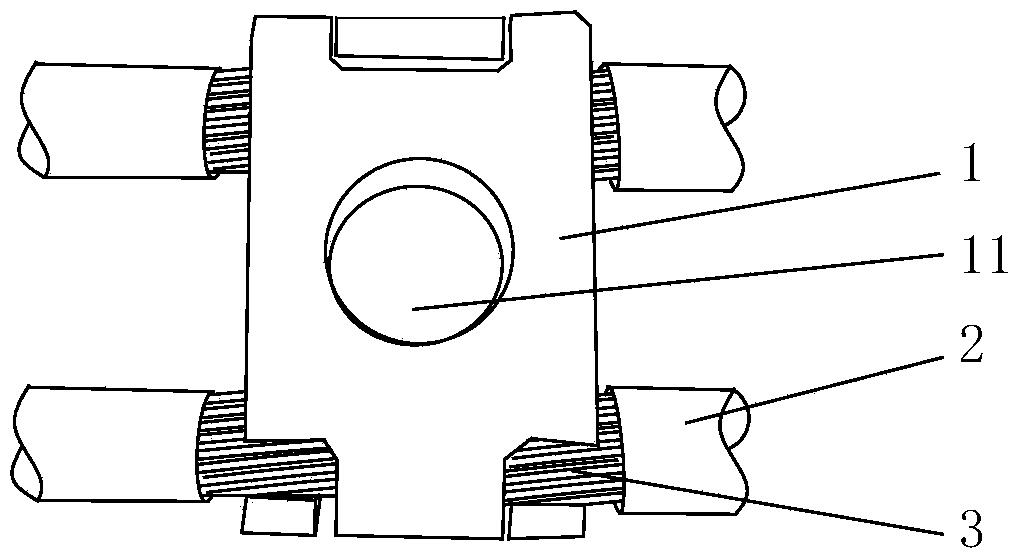

[0026] Now in conjunction with accompanying drawing, the present invention will be further described:

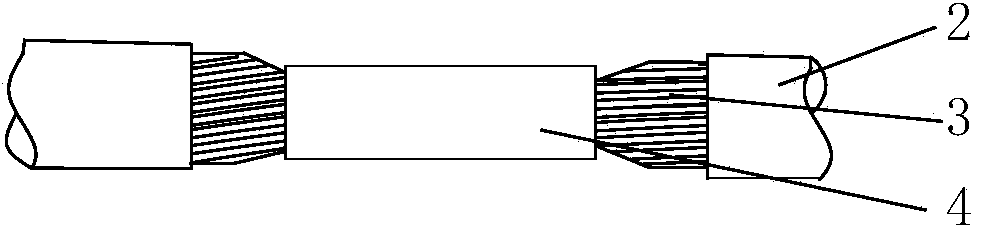

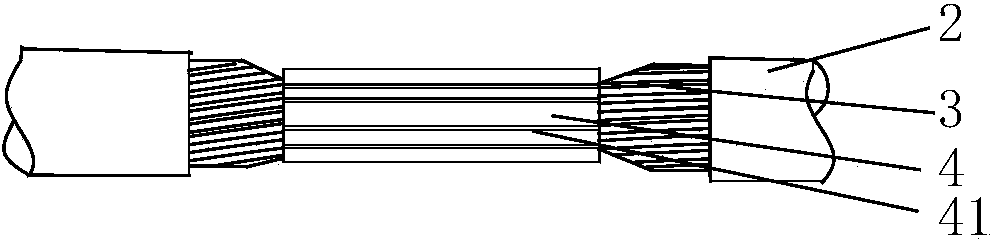

[0027] As shown in the figure, a cable lead-out electrode includes: a cable 3, a metal sleeve 4 is tightly sheathed on the outside of the cable 3, and the inner diameter of the metal sleeve 4 is smaller than the outer diameter of the cable 3 outside the metal sleeve 4 .

[0028] The metal sleeve 4 can be an open metal sleeve or a closed metal sleeve.

[0029] The cable 3 includes a cable 3 with a sheath 2, the cable 3 in the metal sleeve 4 does not have the sheath 2, and the sheath 2 can be peeled off.

[0030] A punching die for a cable lead-out electrode, such as Figure 6 As shown, it includes: an upper mold 61 and a lower mold 62, and the upper mold 61 and the lower mold 62 are provided with a circular hole 63 having the same outer diameter as the metal sleeve 4, wherein half of the circular hole 63 is located in the upper mold, and the other half is located in the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com