Alkyl (meth)acrylate-based thermoplastic resin composition and thermoplastic resin having adjusted scratch resistance and yellowness

一种丙烯酸烷基酯、热塑性树脂的技术,应用在基于(甲基)丙烯酸烷基酯的热塑性树脂组合物和具有调节的耐划伤性和泛黄度的热塑性树脂领域,能够解决低冲击强度和注塑性能、低耐化学性和耐划伤性等问题,达到高光泽度、低泛黄度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

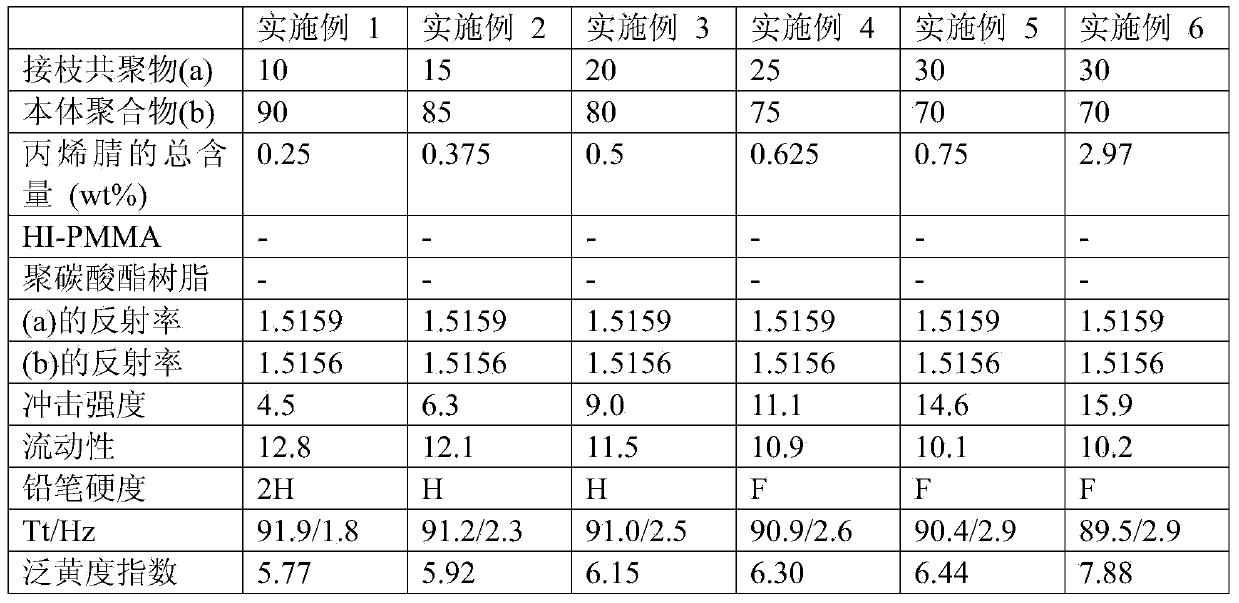

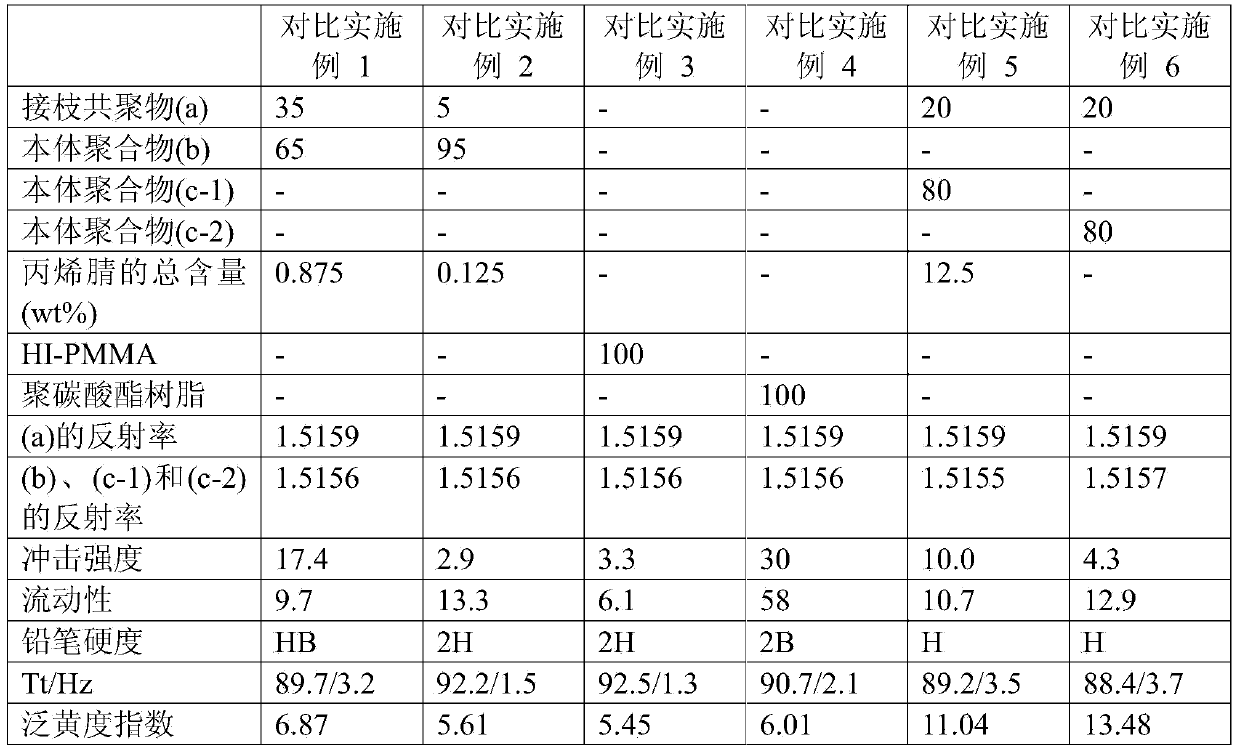

Examples

Embodiment 1

[0063] (a) Preparation of graft copolymer

[0064] (i) Preparation of small particle size rubber polymer

[0065] 45 parts by weight of 1,3-butadiene, potassium rosinate of 1.2 parts by weight, potassium oleate of 1.5 parts by weight, sodium carbonate (Na 2 CO 3 ), 0.5 parts by weight of potassium bicarbonate (KHCO 3 ), 0.3 parts by weight of tert-dodecanemercaptan and 100 parts by weight of ion-exchanged water were simultaneously added to a polymerization reactor (autoclave) purged with nitrogen, and the temperature of the reactor was raised to 55°C. Then, 0.3 parts by weight of potassium persulfate was added to the reactor to initiate a reaction.

[0066] After the reaction was performed for 10 hours, 0.05 parts by weight of t-dodecylmercaptan was further added thereto. The reaction was continued at 65° C. for 8 hours to terminate, and a rubber polymer with a small particle size was obtained.

[0067] The prepared small particle rubber polymer had a gel content of 90%, ...

Embodiment 2

[0082] The procedure was carried out in the same manner as in Example 1, except that 15 wt% of the graft copolymer and 85 wt% of the bulk polymer were used.

Embodiment 3

[0084] Except using 20wt% graft copolymer and 80wt% bulk polymer, it was carried out in the same manner as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| gel fraction | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com