Rear drive electric forklift multifunctional wet axle

An electric forklift, multi-functional technology, applied in the field of forklifts, can solve the problems of poor longitudinal and lateral stability of the whole vehicle, insufficient braking force, large interior space of the whole vehicle, etc. , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

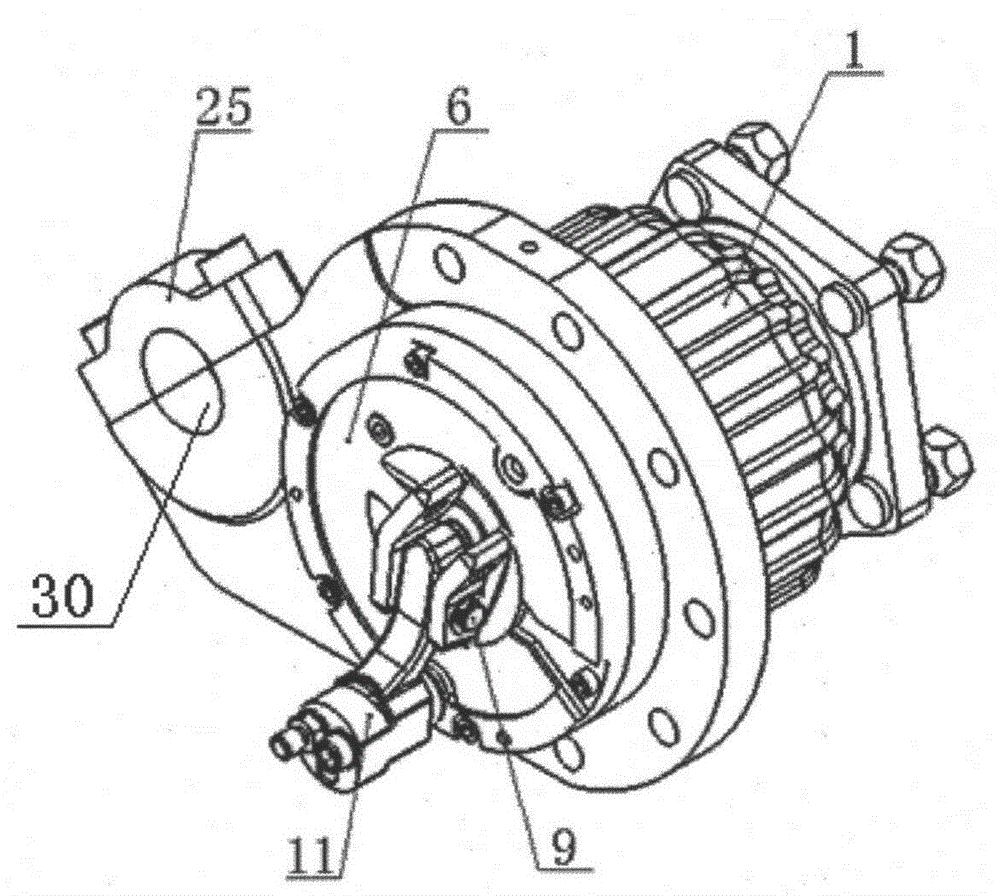

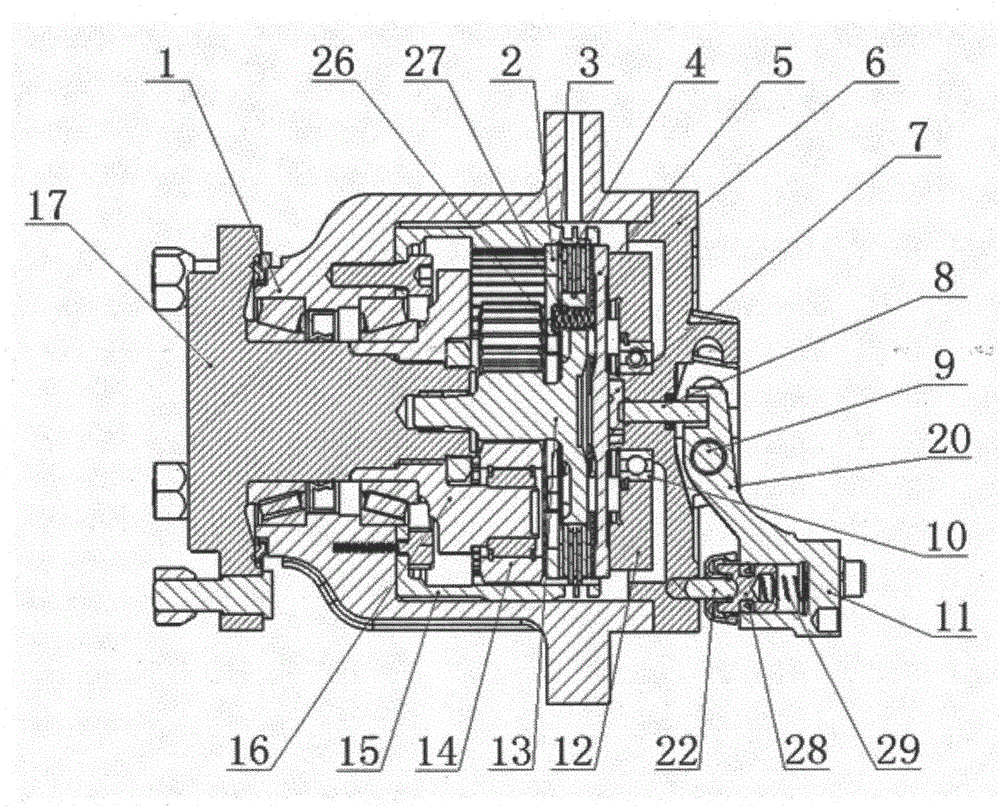

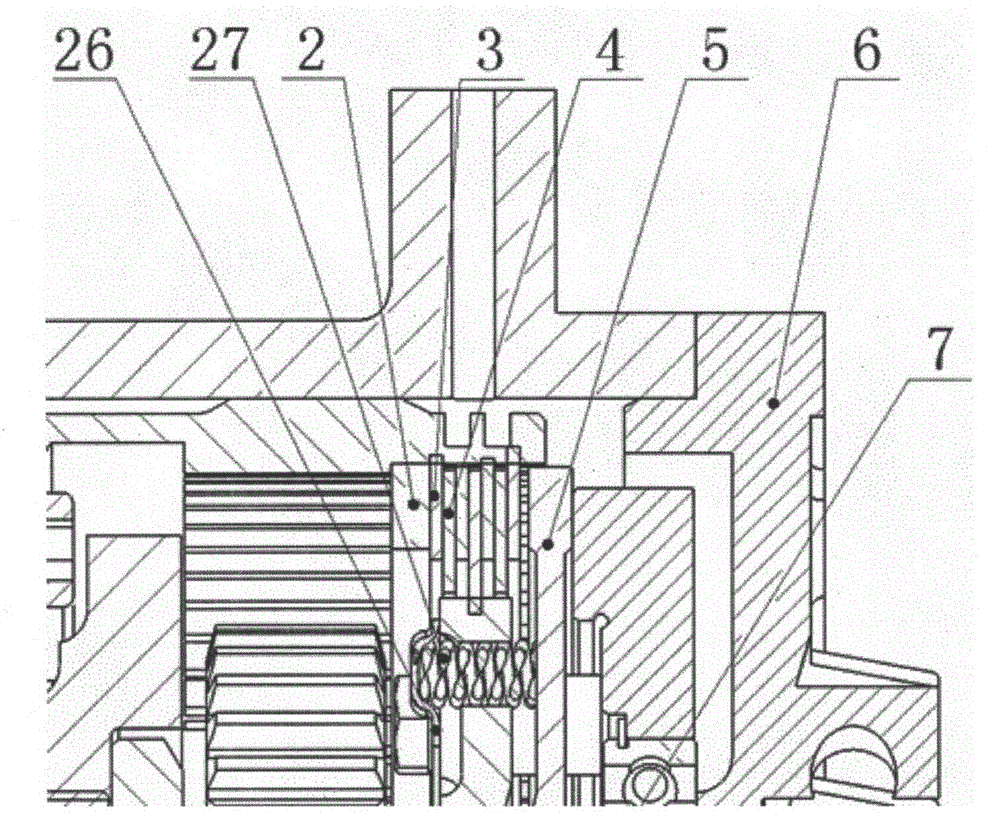

[0030] Benyouming is a multi-functional wet bridge for rear-drive electric forklifts, such as Figure 1-Figure 3 As shown, it mainly consists of output half shaft 17, planetary carrier 16, planetary gear assembly 14, ring gear 15, sun gear 13, friction plate 3, spacer 4, piston 5, brake cylinder assembly 11, housing 1. The shell cover 6 and other components. A bearing cover 25 is installed on the housing 1, and a mounting hole 30 is formed between the bearing cover 25 and the housing 1, thereby realizing the sinking of the fulcrum of the door frame. One end of the output half shaft 17 is connected to the planet carrier 16 through an internal spline, and the planet carrier 16 is axially limited by a lock nut; the three planetary wheel assemblies 14 are riveted on the planet carrier 16 (such as Figure 7 As shown), the planetary g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com