sealed box

A packaging box and sealing effect technology, applied in the field of packaging boxes, can solve the problems of waste, poor sealing performance, and plastic products can only be used once, so as to prevent the penetration of oxygen and water vapor, good sealing effect, and avoid food The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

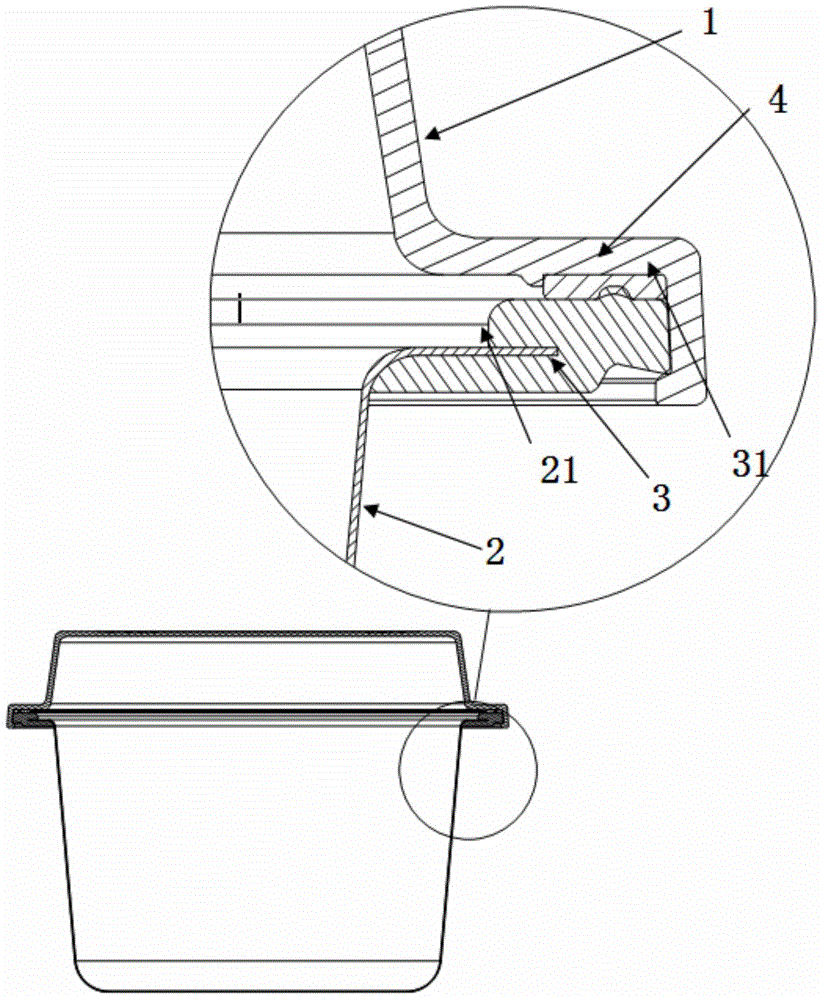

[0016] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 1 as standard.

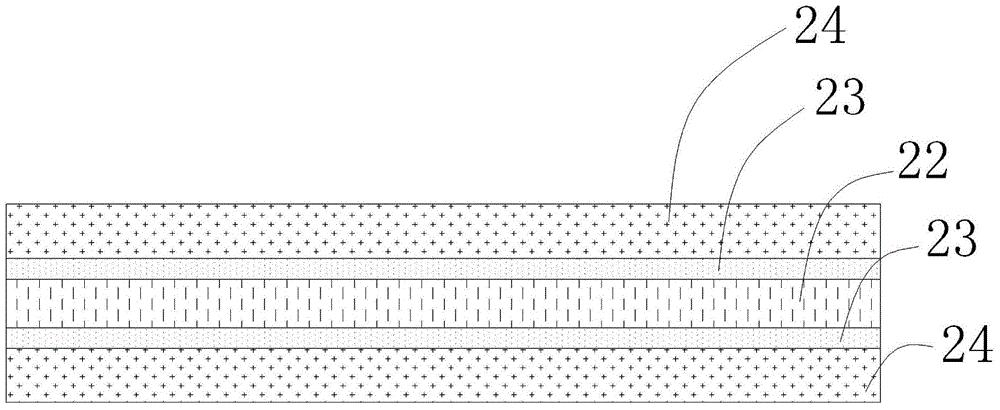

[0017] like figure 1 As shown, the sealed packaging box of the present invention includes a box cover 1, a box body 2 and an injection molding ring 3. The box cover 1 is made of LDPE material through an injection molding process. The end of the box cover 1 is formed with an undercut position 11. The box body 2. It is made of three-layer or more than three-layer co-extruded materials through the blister process. The opening end of the box body 2 is bent outwards and extended to form a ring-shaped box edge material 21. The box edge material 21 is A ring-shaped table top surrounds the opening of the box body 2, and an annular injection molding ring 3 is provided on the outer end of the box mouth edge material 21. The injection molding ring 3 is formed on the edge of the box mouth edge material 21 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com