Method for processing waste water of acid leaching and deironing of potassium feldspar

A waste water treatment, potassium feldspar technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of polluted environment, high cost, waste water discharge, etc., and achieve quality High efficiency, low cost and fast efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

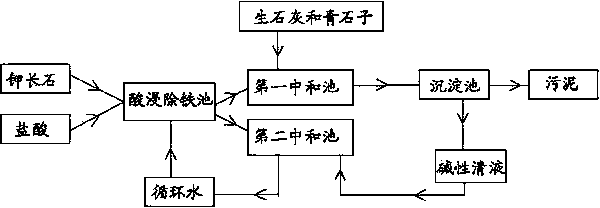

[0018] Such as figure 1 As shown, taking the treatment of 1 ton of potassium feldspar as an example, a kind of potassium feldspar acid leaching iron removal wastewater treatment process steps are as follows:

[0019] 1) Potassium feldspar acid leaching to remove iron

[0020] Measure 1m30% industrial hydrochloric acid or waste sulfuric acid in the acid leaching iron removal pool, weigh 1 ton of ground potassium feldspar and put it into the acid leaching iron removal pool, mix evenly with a circulation pump, acid leaching at room temperature for 2-3 days, After obtaining the potassium feldspar after acid leaching to remove iron, the hydrochloric acid or waste sulfuric acid acid solution is pumped out for recycling;

[0021] 2) Wash potassium feldspar

[0022] First wash the potassium feldspar after acid leaching and iron removal in step 1) with 2m3 circulating water for 6 times, collect the first washing liquid after washing the potassium feldspar in the first neutralization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com