Preparation method of banana composite fruit vinegar

A compound fruit wine and banana technology, applied in the field of food processing, can solve the problems of affecting the mass transfer process, less flavor of fruit vinegar, improving production efficiency, prolonging fermentation time, etc., to improve acetic acid resistance, suitable for a wide range of people, fruit Intense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of banana compound fruit vinegar, comprising the steps of:

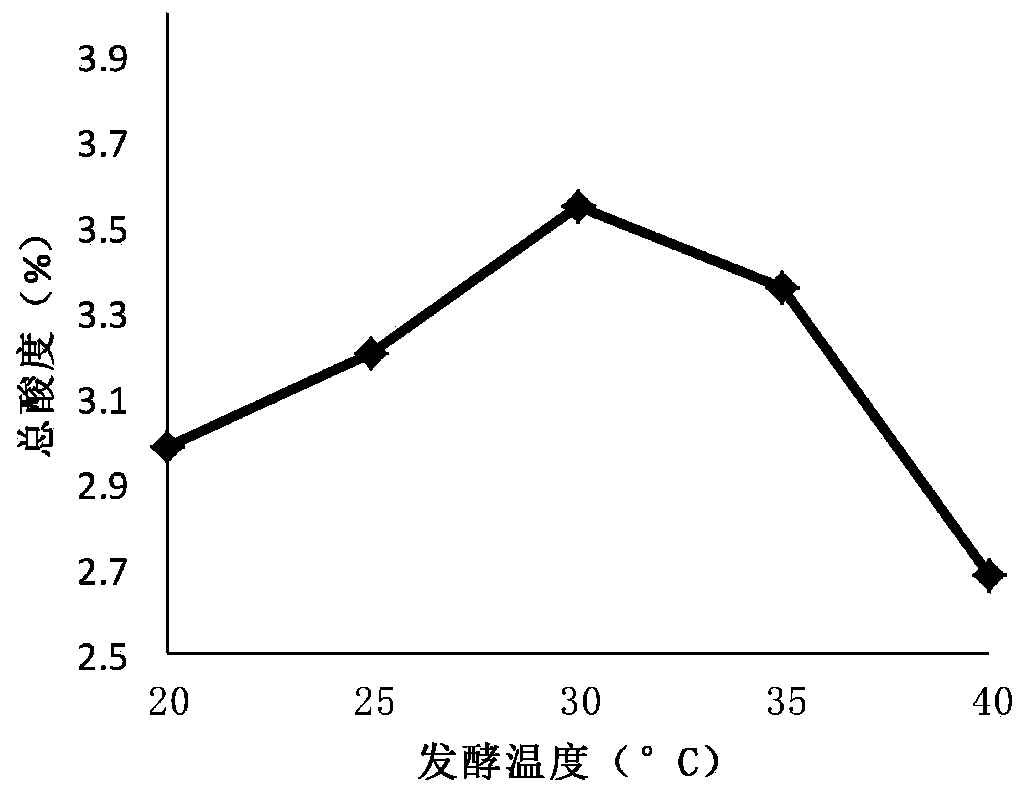

[0034] (1) get the pulp of banana pulp, longan pulp and passion fruit by the weight ratio of 20:10:10, add the pectinase of 0.2% of mixture gross mass after mixing, then add the drinking water of 2 times of mixture gross mass, Slurry, enzymatic hydrolysis at 30°C for 30 minutes, centrifugation, take the upper layer of fruit juice, add sugar solution 4 times the volume of the fruit juice to obtain the first pre-fermentation material; the sugar solution contains white sugar with a mass fraction of 12%;

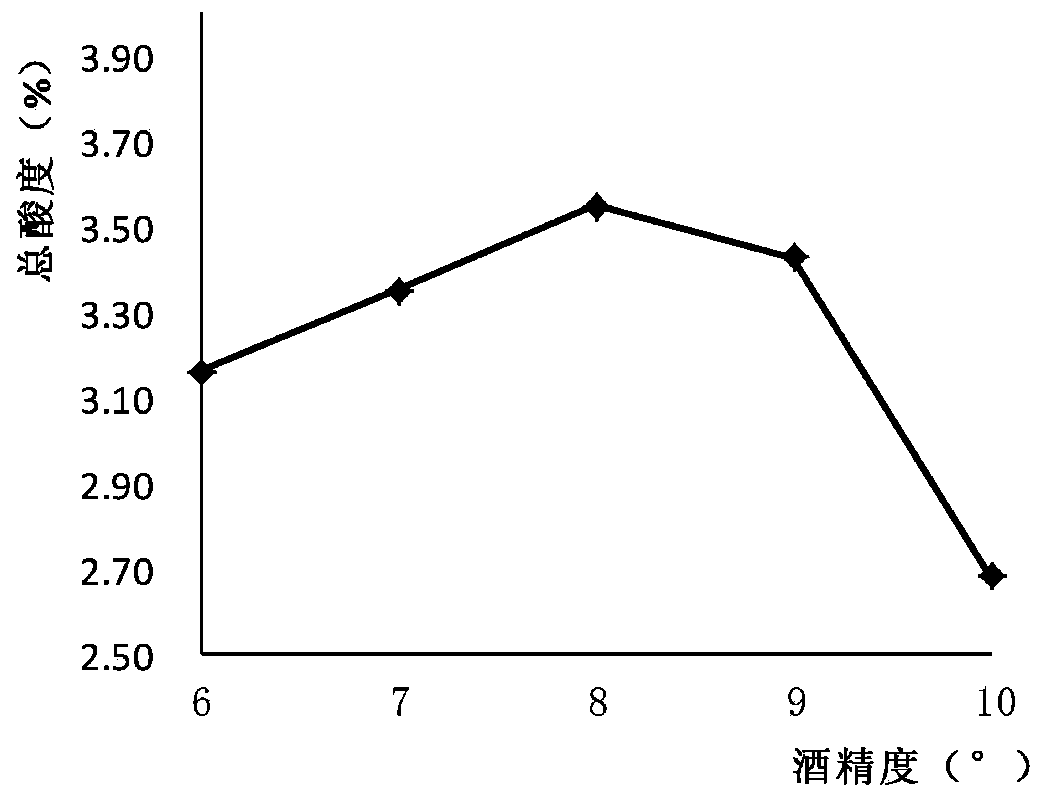

[0035] (2) Add 0.05% of its quality yeast to the first pre-fermentation material in step (1), carry out anaerobic fermentation at 25°C, the alcohol content of the material to be fermented is 6°, and obtain banana compound fruit wine;

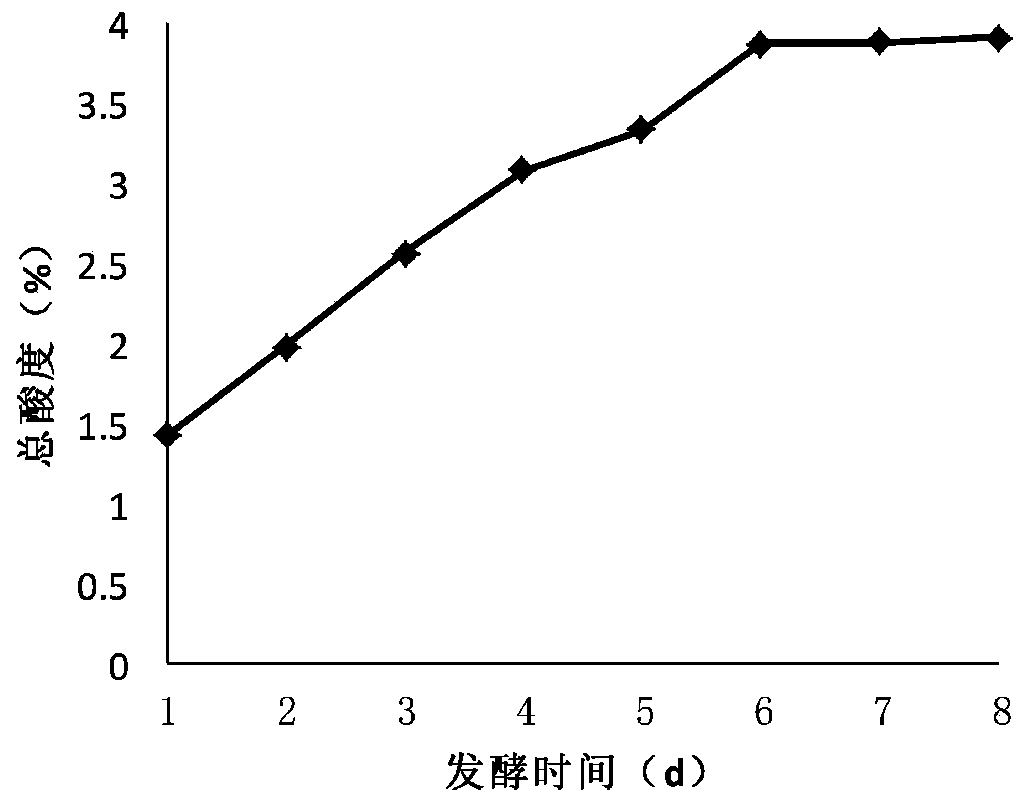

[0036] (3) Take dried acetic acid bacteria, dissolve them in purified water, add corn cobs, and obtain a load rate of acetic acid bacteria of 2.0×10 after 24 ...

Embodiment 2

[0039] A preparation method of banana compound fruit vinegar, comprising the steps of:

[0040] (1) get the pulp of banana pulp, longan pulp and passion fruit by the weight ratio of 50:20:20, add the pectinase of mixture gross mass 0.23% after mixing, then add the drinking water of 2.2 times of mixture gross mass, Slurry, enzymatic hydrolysis at 33°C for 28 minutes, centrifugation, take the upper layer of fruit juice, add sugar solution 4.3 times the volume of the fruit juice, to obtain the first pre-fermentation material; the sugar solution contains white sugar with a mass fraction of 13%;

[0041] (2) Add 0.06% of its quality yeast to the first pre-fermentation material in step (1), carry out anaerobic fermentation at 24°C, the alcohol content of the material to be fermented is 7°, and obtain banana compound fruit wine;

[0042] (3) Take dried acetic acid bacteria, dissolve them in purified water, add loofah, and obtain a loading rate of acetic acid bacteria of 3.2×10 after ...

Embodiment 3

[0045] A preparation method of banana compound fruit vinegar, comprising the steps of:

[0046] (1) get the pulp of banana pulp, longan pulp and passion fruit by the weight ratio of 27:18:14, add the pectinase of mixture gross mass 0.25% after mixing, then add the drinking water of 2.4 times of mixture gross mass, Slurry, enzymatic hydrolysis at 35°C for 26 minutes, centrifugation, take the upper layer of fruit juice, add 4.5 times the volume of fruit juice sugar solution to obtain the first pre-fermentation material; the sugar solution contains white sugar with a mass fraction of 14%;

[0047] (2) Add 0.07% of its quality yeast to the first pre-fermentation material in step (1), carry out anaerobic fermentation at 23°C, the alcohol content of the material to be fermented is 8°, and obtain banana compound fruit wine;

[0048] (3) Take dried acetic acid bacteria, dissolve them in purified water, add bagasse, and obtain a load rate of acetic acid bacteria of 4.5×10 after equilib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com