Method for preparing polyvinyl alcohol rice straw composite material

A polyvinyl alcohol and composite material technology, which is applied in the field of preparing polyvinyl alcohol rice straw composite materials, can solve the problems of unfavorable rice straw full bonding, difficulty in achieving uniform distribution, and affecting material performance, so as to increase user affinity and uniform performance , good color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

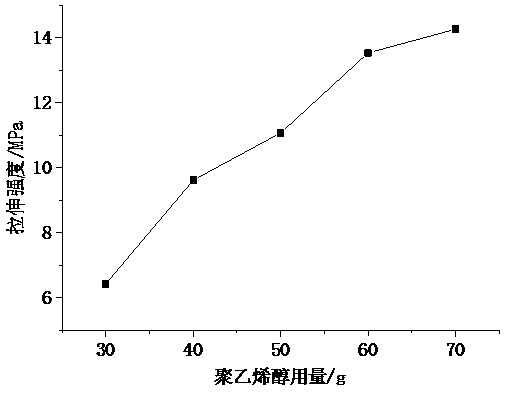

[0020] After the rice straw is dried in the sun, it is chopped into small sections of 2 cm. Weigh 100 grams of chopped rice straw and place it in a stirring tank. Weigh 40 grams of polyvinyl alcohol, add it to 620 mL of water, and stir to dissolve at 90°C. Pour the polyvinyl alcohol solution into the mixing tank filled with crushed rice straw while it is hot, and stir evenly. Put the wet material in a stainless steel pan, dry it at 65°C until the water content is 20%, stir or tear it intermittently to prevent it from forming into large pieces. The dried material was put into a mold, and then hot-pressed at 150°C and 18MPa for 15min. After cooling to room temperature, unmould and trim. The tensile strength of the composite material reaches 9.62MPa.

Embodiment 2

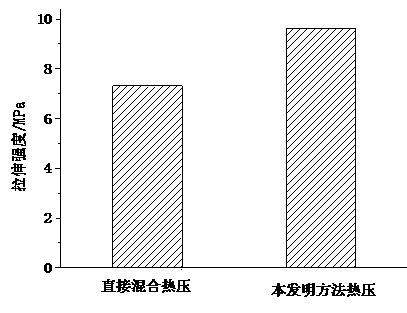

[0022] After the rice straw is dried in the sun, it is chopped into small sections of 3 cm, and then cut and pulverized by an anchor grinder. Weigh 100 grams of crushed rice straw and place it in a stirring tank. Weigh 40 grams of polyvinyl alcohol, add it to 620 mL of water, and stir to dissolve at 90°C. Pour the polyvinyl alcohol solution into the mixing tank filled with crushed rice straw while it is hot, and stir evenly. Put the wet material in a stainless steel pan, dry it at 65°C until the water content is 20%, stir or tear it intermittently to prevent it from forming into large pieces. The dried material was put into a mold, and then hot-pressed at 150°C and 18MPa for 15min. After cooling to room temperature, unmould and trim. The tensile strength of the composite material reaches 10.35MPa.

Embodiment 3

[0024] The rice straw is dried in the sun and crushed by a straw crusher. Weigh 100 grams of crushed rice straw and place it in a stirring tank. Weigh 30 g of polyvinyl alcohol, add it into 450 mL of water, and stir to dissolve at 90°C. Pour the polyvinyl alcohol solution into the mixing tank filled with crushed rice straw while it is hot, and stir evenly. Put the wet material in a stainless steel pan, dry it at 80°C until the water content is 15%, stir or tear it intermittently to prevent it from forming into large pieces. The dried material was put into a mold, and then hot-pressed at 145°C and 12MPa for 13min. After cooling to room temperature, unmould and trim. The tensile strength of the composite material reaches 8.04MPa.

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com