Waterproof and elastic fabric

A technology of elastic fabric and waterproof coating, applied in textile, yarn, fabric and other directions, can solve the problems of poor appearance and hand feeling, and achieve the effect of low cost, good waterproof breathability and excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Using hard staple fibers as surface fibers, using composite polyester filament fibers as skeleton fibers, blending to form a core-spun composite yarn in which hard staple fibers are coated with composite polyester filament fibers, and then spraying a waterproof coating agent; Through, sizing, threading, weaving, and finishing processes, the waterproof elastic fabric is made; the hard short fibers account for 70%, and the composite polyester filament fibers account for 30%, and the composite polyester filament fibers are made of polymethane Made of butylene dicarboxylate and polybutylene terephthalate.

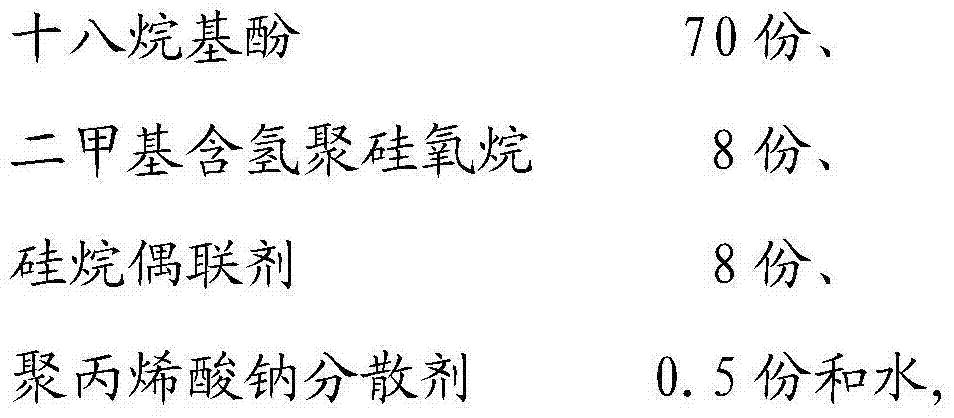

[0012] Described waterproof coating agent is made up of the following components by weight:

[0013]

[0014] After the components are mixed, water is added to form a waterproof coating agent with a water content of 40%.

[0015] The composite polyester filament fiber is prepared by the following method: after blending polybutylene isophthalate and polybutylene terep...

Embodiment 2

[0017] Using hard staple fibers as surface fibers, using composite polyester filament fibers as skeleton fibers, blending to form a core-spun composite yarn in which hard staple fibers are coated with composite polyester filament fibers, and then spraying a waterproof coating agent; Through, sizing, threading, weaving, and finishing processes, waterproof elastic fabrics are made; the hard short fibers account for 85%, and the composite polyester filament fibers account for 15%, and the composite polyester filament fibers are made of polymethane Made of butylene dicarboxylate and polybutylene terephthalate.

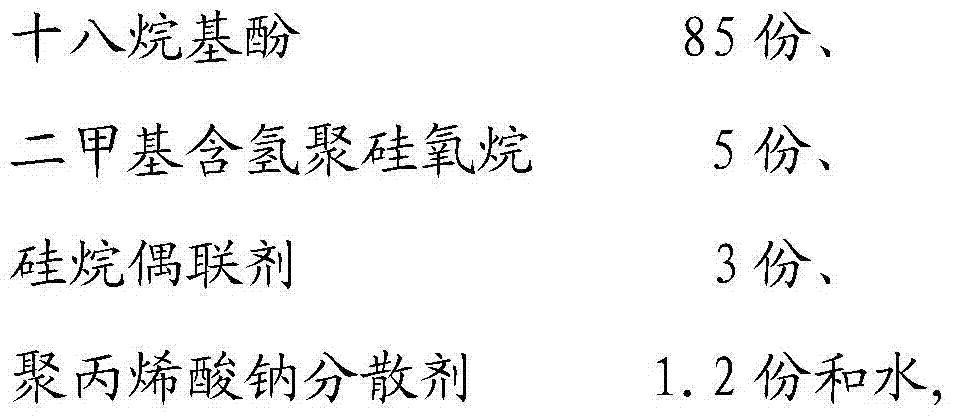

[0018] Described waterproof coating agent is made up of the following components by weight:

[0019]

[0020] After the components are mixed, water is added to form a waterproof coating agent with a water content of 20%.

[0021] The composite polyester filament fiber is prepared by the following method: after blending polybutylene isophthalate and polybutylene terepht...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com