Method of color fixation for dyeing fabric made of acid dye

A technology of acid dyes and color treatment, applied in the field of fabric dyeing and finishing, can solve the problems of small molecular weight, poor wet fastness, and transfer of strong acid dyes, and achieve the effects of improved color fastness of fabrics, low price, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of method that the dyed fabric of acid dye is carried out color fixing treatment, comprises the steps:

[0021] (1) Preparation of silicon-containing hydrosol;

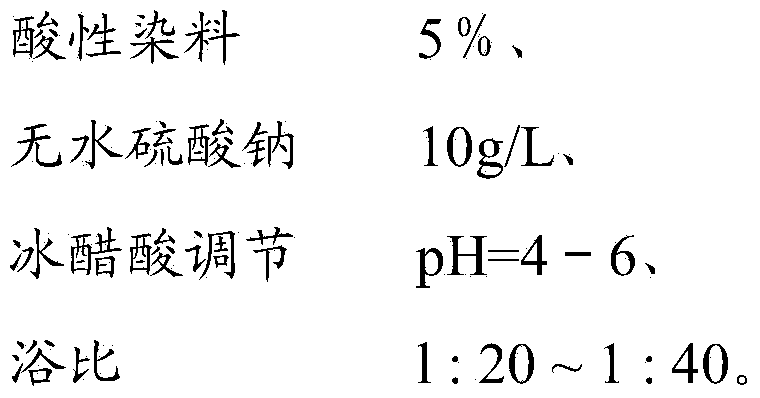

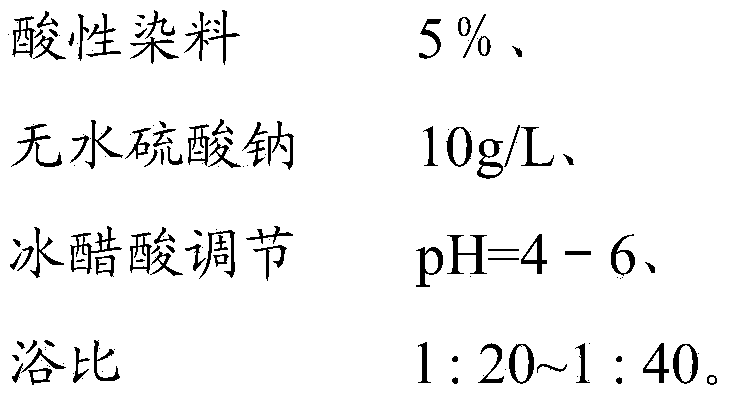

[0022] (2) Dyeing: Dip the silk fabric in the dye prepared with acid red G, adjust the pH of the dye to 4, and the liquor ratio is 1:20, do not wash it after dyeing, roll it on a padding machine, and then heat it at 60°C drying;

[0023] (3) Sol color fixing treatment: use the silicon-containing hydrosol prepared in step (1) to treat the fabric dyed in step (2), and the fabric is dipped and rolled twice in the sol, with a pressure of 4kg / cm 2 , with a liquid loading rate of 60%, pre-baked in an oven at 50°C for 20 minutes, and then baked at 170°C for 10 minutes.

Embodiment 2

[0025] A kind of method that the dyed fabric of acid dye is carried out color fixing treatment, comprises the steps:

[0026] (1) Preparation of silicon-containing hydrosol;

[0027] (2) Dyeing: Dip the nylon fabric in the dye prepared with brilliant blue RAW, adjust the pH of the dye to 5, and the bath ratio 1:30. drying;

[0028] (3) Sol color fixing treatment: use the silicon-containing hydrosol prepared in step (1) to treat the fabric dyed in step (2), and the fabric is dipped and rolled twice in the sol, with a pressure of 4kg / cm 2 , with a liquid loading rate of 65%, pre-baked in an oven at 60°C for 10 minutes, and then baked at 160°C for 10 minutes.

Embodiment 3

[0030] A kind of method that the dyed fabric of acid dye is carried out color fixing treatment, comprises the steps:

[0031] (1) Prepare Si / Ti composite hydrosol, wherein the molar ratio of silicon to titanium is Si:Ti=5:1;

[0032] (2) Dyeing: Dip the silk fabric in the dye prepared with acid medium black T, adjust the pH of the dye to 5, and the liquor ratio is 1:30. ℃ drying;

[0033] (3) Sol color fixing treatment: use the silicon-containing hydrosol prepared in step (1) to treat the fabric dyed in step (2), and the fabric is dipped and rolled twice in the sol, with a pressure of 4kg / cm 2 , with a liquid-carrying rate of 70%, pre-bake in an oven at 70°C for 10 minutes, and then bake at 160°C for 8 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com